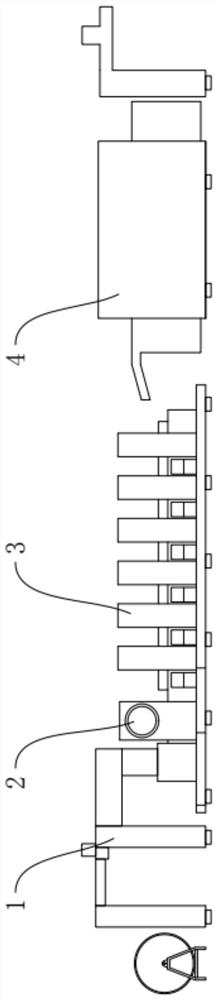

Online sizing and printing system and process based on single-pass digital printing machine

A technology of digital printing machine and printing process, applied in the field of fabric printing, can solve problems such as affecting the stability of printing quality, affecting the printing production process, blocking the nozzles of printing, and saving drying process costs, saving raw material costs, The effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

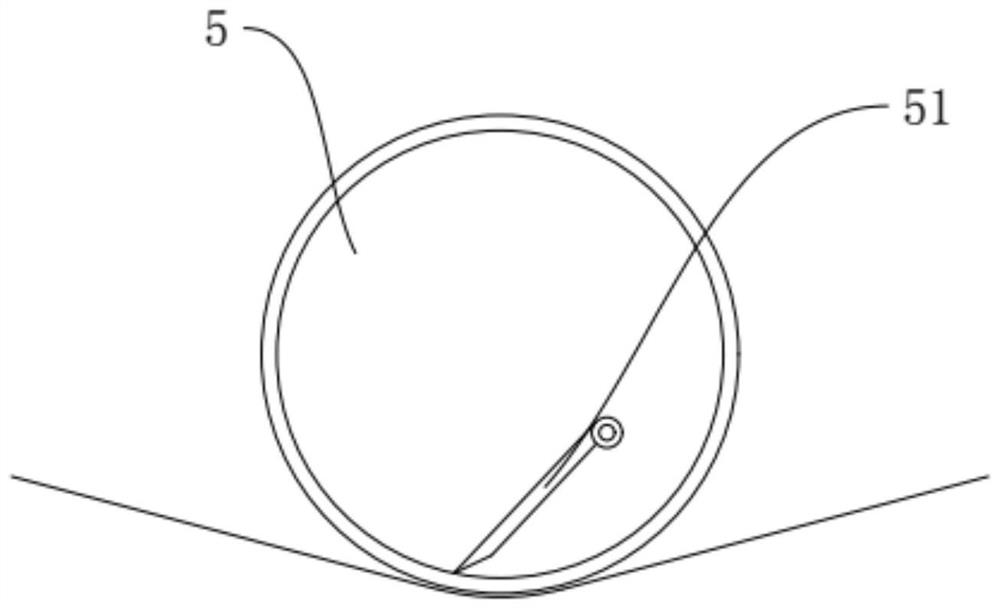

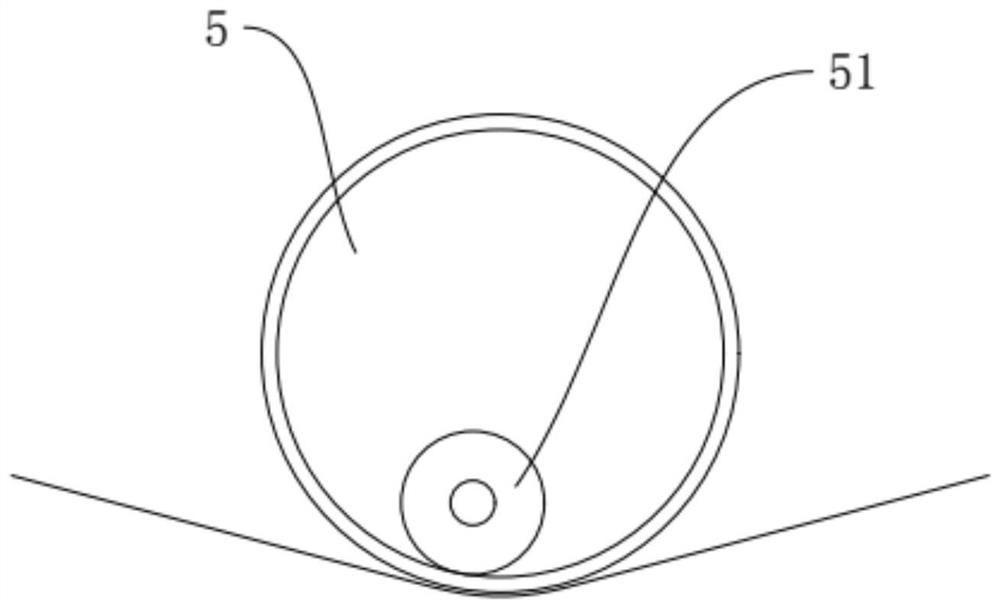

[0049] This embodiment discloses an online sizing printing system based on a single-pass digital printing machine. On the basis of Embodiment 1, refer to Figure 1-7 Shown in detail, the cylinder screen sizing device in the printing system specifically includes a sizing cylinder 5 and a scraping structure 51, a certain amount of foaming slurry is accumulated in the sizing cylinder 5, and the fabric is drawn from the underside of the sizing cylinder 5. Bypassing to achieve sizing; the scraping structure 51 is located on the inner side of the sizing cylinder 5, and presses against the inner peripheral lower side of the sizing cylinder 5, and can squeeze the foaming slurry input into the sizing cylinder 5, and the slurry is transparent. The over-sizing cylinder 5 is coated on the fabric to realize sizing; the scraping structure 51 can use a cylindrical extrusion cylinder 13 or a slurry scraper to squeeze and coat the slurry.

[0050] The sizing cylinder 5 is a cylindrical structu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com