Leakproof humidifying composite hollow fiber membrane as well as preparation method and application thereof

A fiber membrane and hollow technology, which is applied in the field of leak-proof and humidification composite hollow fiber membrane preparation, can solve the problems of electrode submersion, low power generation efficiency, poor humidification effect, etc. Catch-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

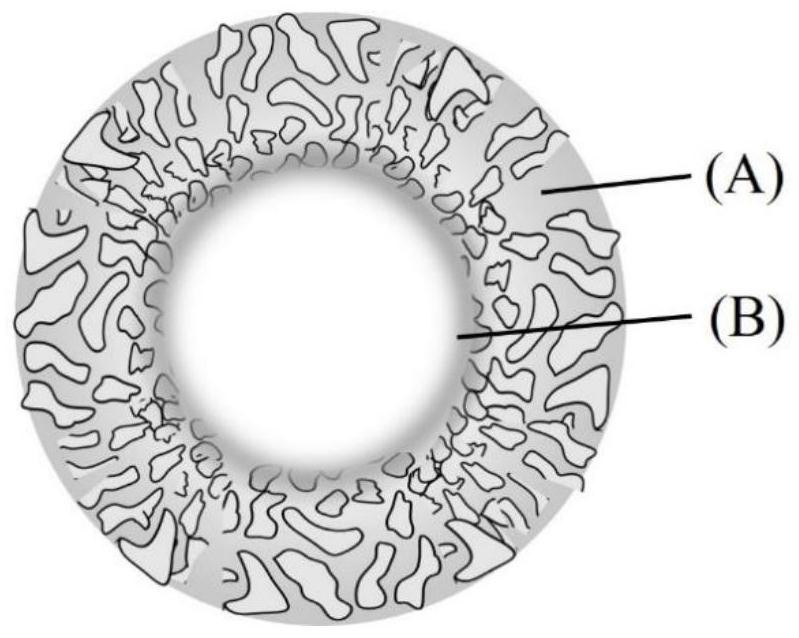

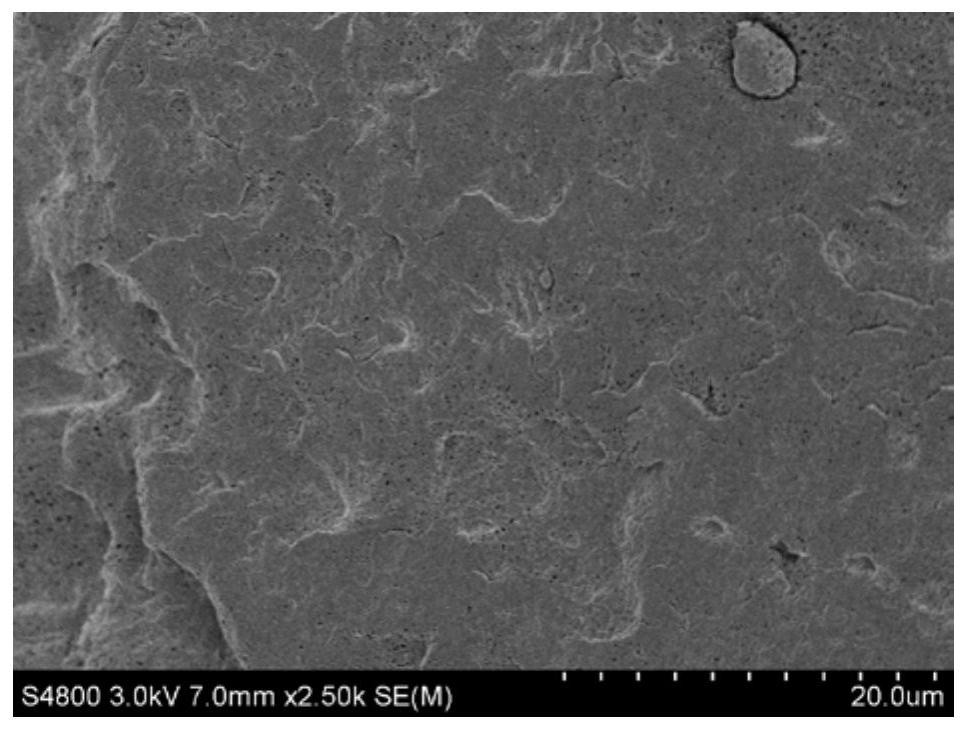

[0042] Embodiment 1 A kind of anti-leakage humidification composite hollow fiber membrane, its preparation method comprises:

[0043] (1) Preparation of spinning casting solution: Prepare spinning casting solution according to the ratio of 19.0wt% cellulose acetate powder, 71.0wt% N,N-dimethylformamide, 10.0wt% PEG2000, specifically, acetic acid After the cellulose powder is vacuum-dried at 50°C for 24 hours to remove moisture, it is dissolved in N,N-dimethylformamide organic solvent, then added with PEG2000 hydrophilic modifier, mechanically stirred for 36 hours and defoamed for 48 hours to obtain a uniform Transparent spinning casting solution, for subsequent use;

[0044] (2) Immersion precipitation phase transfer method: use a hollow fiber spinning machine to spin, and under 1.0MPa, the spinning casting liquid obtained in step (1) is extruded from the spinneret together with the core liquid, wherein the core The liquid is water, and the external coagulation bath is a mixe...

Embodiment 2

[0046] Embodiment 2 A kind of anti-leakage humidification composite hollow fiber membrane, its preparation method comprises:

[0047] (1) Preparation of spinning casting solution: Prepare spinning casting solution according to the ratio of 14.0wt% cellulose powder, 84.0wt% N, N-dimethylacetamide, 2.0wt% PVP-K30, specifically the fiber The plain powder is vacuum-dried at 40°C for 24 hours to remove moisture, dissolved in N,N-dimethylacetamide organic solvent, then added with PVP-K30 hydrophilic modifier, mechanically stirred for 6 hours and defoamed for 12 hours to obtain Uniform and transparent spinning casting solution, standby;

[0048] (2) Immersion precipitation phase transfer method: use a hollow fiber spinning machine to spin, and under 0.1MPa, the spinning casting liquid obtained in step (1) is extruded from the spinneret together with the core liquid, wherein the core The liquid is water, and the external coagulation bath is a mixed solution of water and N,N-dimethyla...

Embodiment 3

[0050] Embodiment 3 A kind of anti-leakage humidification composite hollow fiber membrane, its preparation method comprises:

[0051] (1) Preparation of spinning casting solution: prepare spinning casting solution according to the ratio of 24.0wt% polyether modified polysulfone powder, 56.0wt% N-methylpyrrolidone, and 20.0wt% polyvinyl alcohol, specifically, The polyether-modified polysulfone powder is vacuum-dried at 60°C for 24 hours to remove moisture, then dissolved in N-methylpyrrolidone organic solvent, then added with polyvinyl alcohol hydrophilic modifier, mechanically stirred for 72 hours and defoamed for 72 hours, then it is ready Obtain a uniform and transparent spinning solution for subsequent use;

[0052](2) Immersion precipitation phase transfer method: use a hollow fiber spinning machine to spin, and under 2.0MPa, the spinning casting liquid obtained in step (1) is extruded from the spinneret together with the core liquid, wherein the core The liquid is water,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com