Fluid distillation apparatus and method for circulating process fluid

A technology for process fluids and fluids, applied in the direction of control, application, and maintenance of heating chambers using interconnected flow control elements, which can solve problems affecting distillation arrangements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

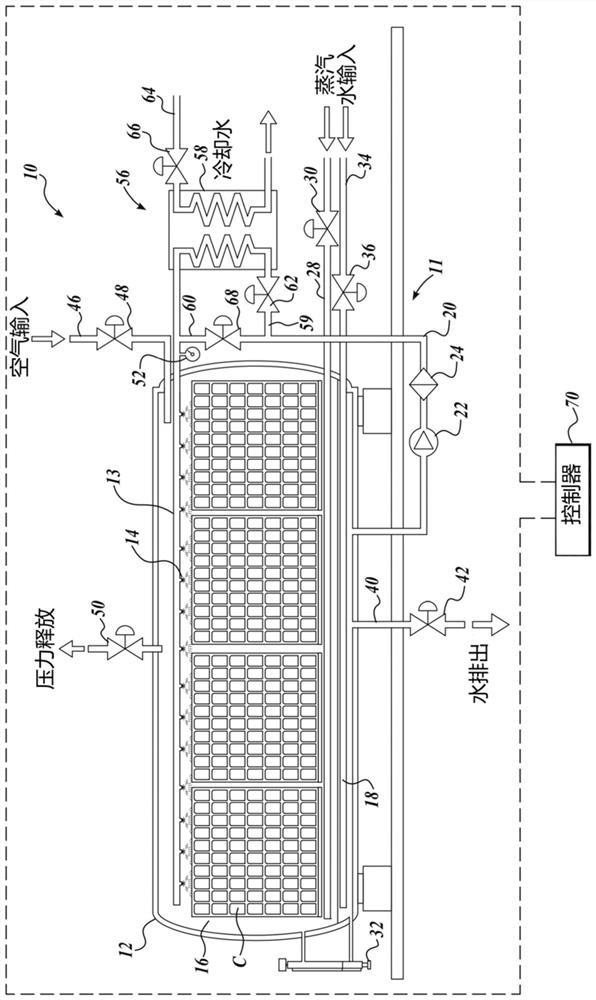

[0031] Embodiments of the present disclosure relate to an improved steam-water spray (SWS) distillation system that provides more uniform processing and faster cooling than prior art systems. In this regard, the improved SWS distillation system is configured to increase the total fluid flow through the still and thus reduce the temperature differential across the load during the cooling phase.

[0032] In general, embodiments of the improved SWS distillation system are achieved by separating the heat exchanger from the main recycle fluid loop and using a separate pump to circulate the process fluid through the heat exchanger. It will be understood from the following description that the advantages of the improved SWS distillation system include at least the following points: no increase in the height of the still; more flexibility in the selection of heat exchangers; the flow rate in the cooling stage can be compared with The flow is the same during the start-up phase and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com