Application of trifluoroethoxy vinyl phosphate in battery electrolyte

A technology of trifluoroethoxy vinyl phosphate and fluoroethoxy vinyl phosphate, which is applied in the field of battery electrolyte additives, can solve the problems of battery capacity loss, increased manufacturing cost, and cumbersome manufacturing process, and achieve good charging and discharging Efficiency and cycle performance, increased storage performance, and effects of improved flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

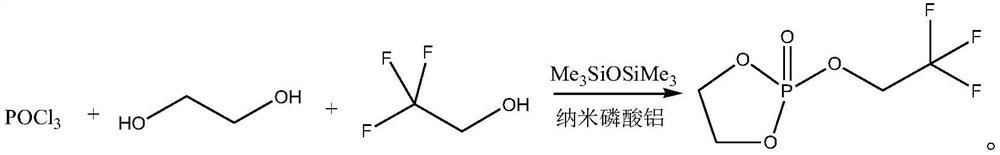

Method used

Image

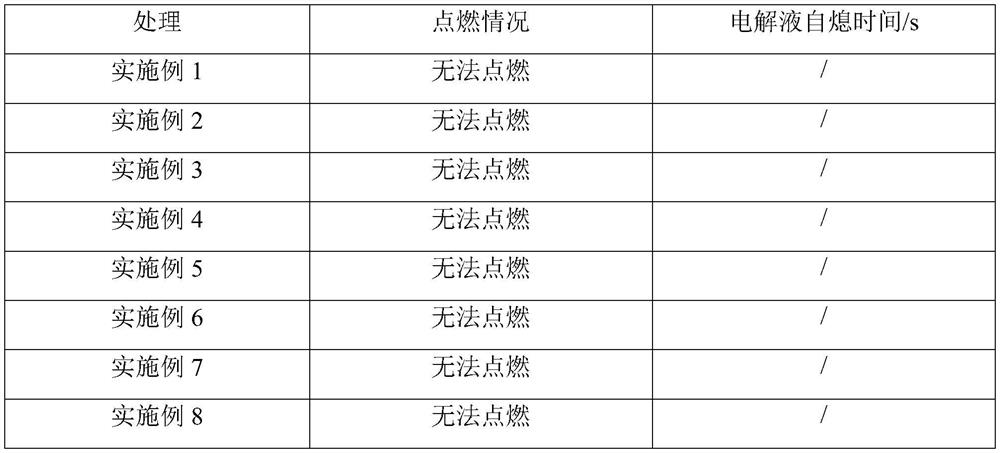

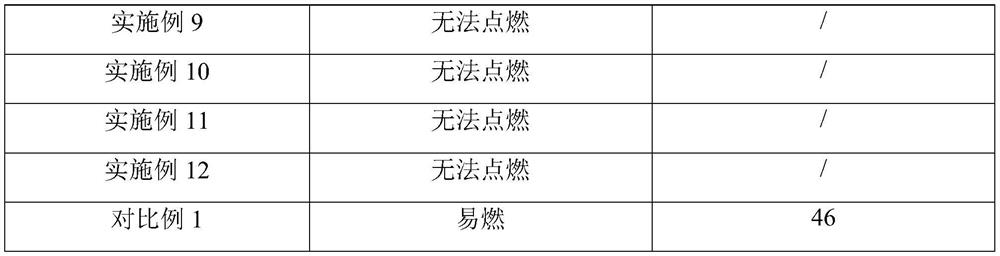

Examples

Embodiment 1

[0019] The battery electrolyte includes a mass ratio of 15: 77.2: 7.8 LIPF 6 However, trifluoroacetate and trifluoroethoxy phosphoric acid vinyl phosphate (99.5% or more purity), the moisture content of 27 ppm, acid value of 39 ppm, oxygen, and oxygen content.

Embodiment 2

[0021] The organic solvent is mixed with a volume ratio of 30: 40:30, a methyl propionate and methyl propionate and trifluoroacetate;

[0022] Take the weight ratio of 1: 2 LIBF 4 LISO 3 CF 3 Common as a lithium salt;

[0023] The battery electrolyte includes a mass ratio of 18: 80: 2, an organic solvent and a trifluoroethoxy phroleter (99.5% or more purity), the obtained battery electrolyte 30 ppm, 41 ppm, oxygen <1 ppm.

Embodiment 3

[0025] The volume ratio of 10: 20: 30: 30: 10: 30: 30: 30: Detethyl carbonate, methyl carbonate, diethyl carbonate and trifluoroacetate mixed organic solvent;

[0026] Take the weight ratio of 1: 2: 1 Liclo 4 , LIN (CF 3 SO 2 ) 2 And LIC (CF 3 SO 2 ) 3 Common as a lithium salt;

[0027] The battery electrolyte includes a mass ratio of 15.6: 83: 1.4, a organic solvent, and trifluoroethoxy phrolene (99.5% or more), the water content of 29 ppm, acid value is 40 ppm, oxygen part of the resulting battery electrolyte <1 ppm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com