Mixed-flow water turbine draft tube with inclined bent cone

A draft tube and water turbine technology, which is applied in the direction of reaction engines, hydroelectric power generation, mechanical equipment, etc., can solve the problems of unstable output, fluctuation, and complex flow of Francis turbines, and achieve improved operation stability and reduced Volatility, the effect of improving stability performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

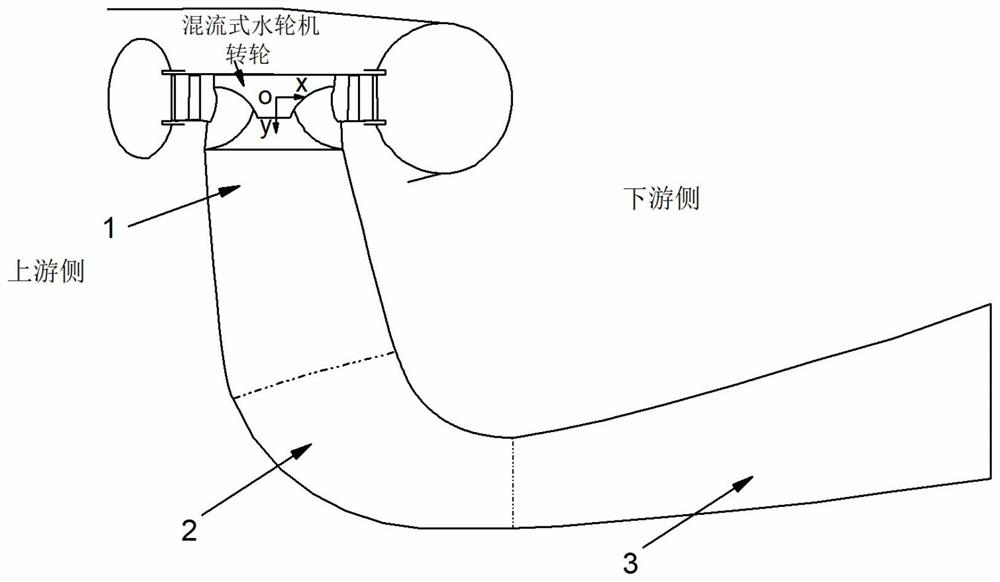

[0028] As shown in the figure, a draft tube of a Francis turbine with an obliquely curved cone includes an obliquely curved cone section unit 1 arranged at the outlet of the Francis turbine runner, and the obliquely curved cone section unit 1 is provided with an elbow section unit 2, The elbow section unit 2 is connected with a diffusion section unit 3 behind it.

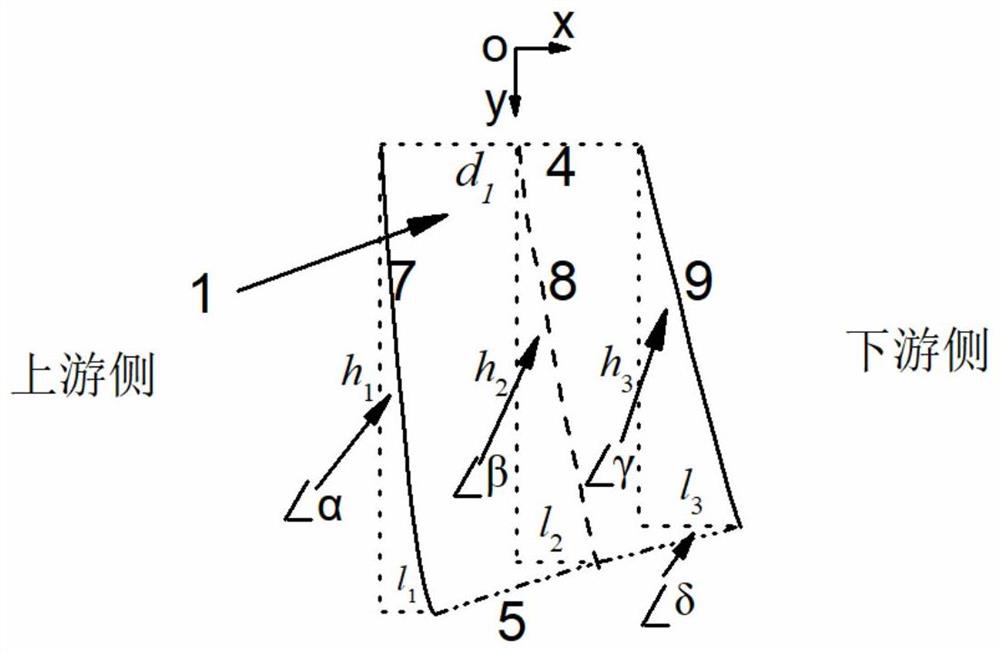

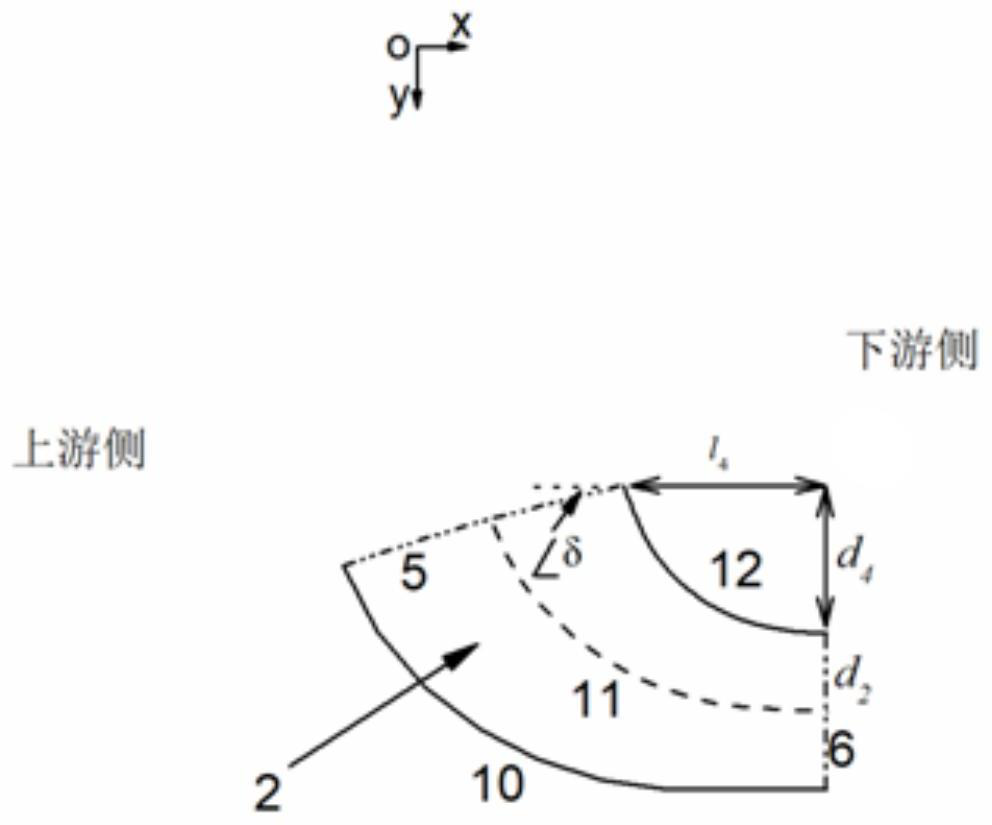

[0029] The inlet diameter d of the oblique cone section unit 1 1 It is equal to the diameter D of the outlet of the Francis turbine runner, from the diameter d 1 Determine the horizontal maximum offset distance l of the end point of the upstream side contour line 7 of the oblique cone unit relative to the starting point 1 and the vertical maximum distance are h 1 , where l 1 / d 1 =0.075~0.3, h 1 / d 1 =1.0~2.0; also by the diameter d 1 Determine the horizontal maximum offset distance l of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com