Biodegradable high-barrier coated paper as well as preparation method and application thereof

A biodegradable and coated paper technology, applied in the field of coated paper, can solve the problems of environmental pollution, biodegradability and other problems, and achieve the goals of alleviating environmental pollution, excellent barrier performance, good oxygen barrier performance and water vapor barrier performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

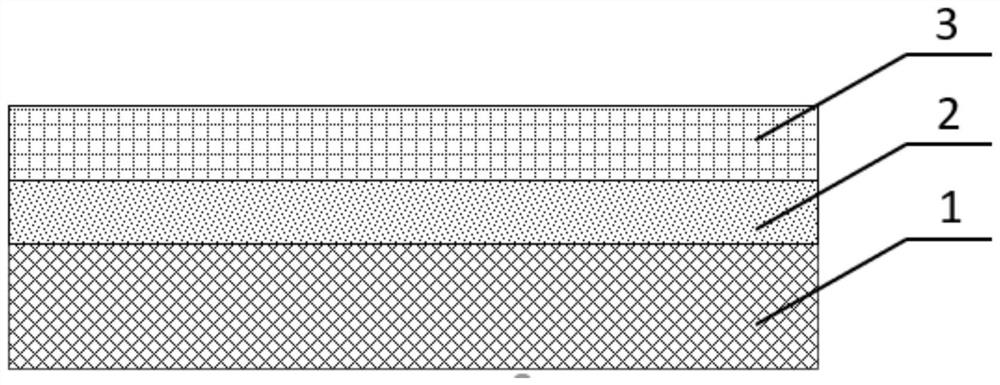

[0044] The invention provides a kind of preparation method of biodegradable high barrier coated paper, comprising the following steps:

[0045] Preparation of S1 barrier layer: Coat the polyvinyl alcohol / nanocellulose composite coating on the base paper surface. After coating, place the coated paper at 40-70°C to dry for 30-120 minutes. The preferred drying method and conditions are: Dry in an oven at 70°C for 60 minutes. The drying method can also be selected according to the needs and conditions: natural drying, hot plate drying, far-infrared drying, vacuum drying, microwave drying, etc.;

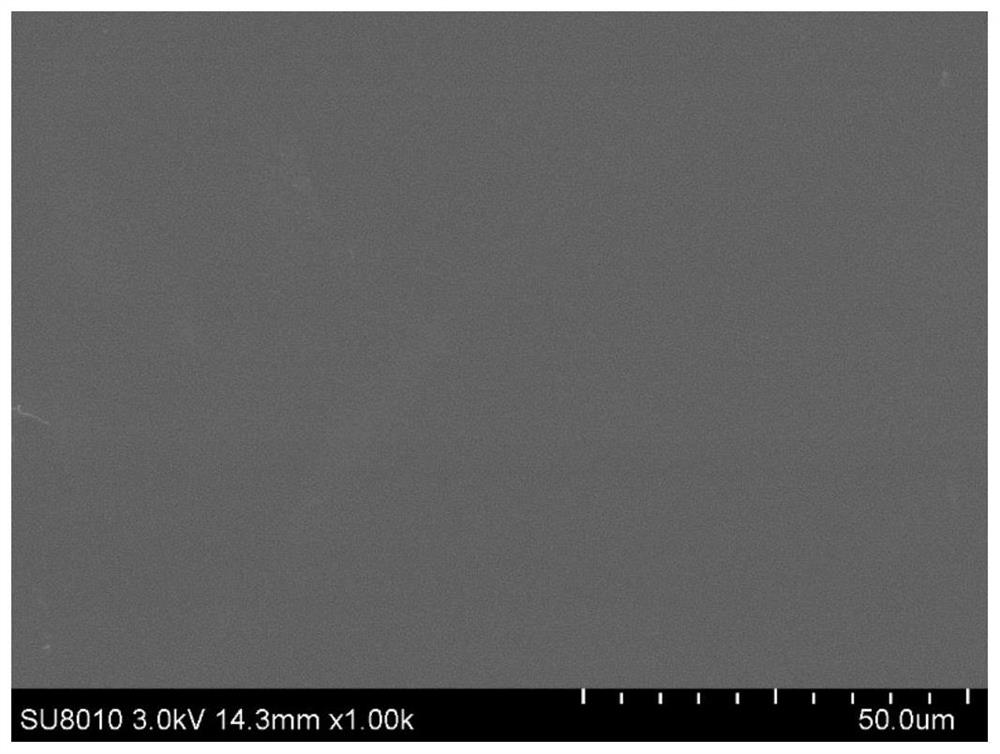

[0046] S2 Preparation of the heat-sealing layer: apply the cellulose acetate solution on the barrier layer obtained in step S1, and after the coating is completed, place the coated paper indoors to dry naturally for 30-120 minutes to obtain the biological Degradable high barrier coated paper.

[0047] In some embodiments of the present invention, in step S1, the coated base paper is sing...

Embodiment 1

[0070] A preparation method of biodegradable high barrier coated paper, comprising the following steps:

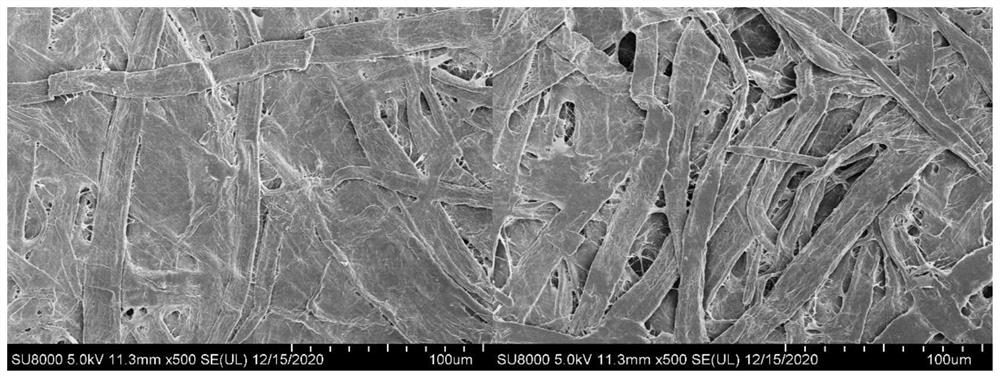

[0071] (1) Preparation of polyvinyl alcohol / nanocellulose composite coating: 8.62g of TEMPO oxidized nanocellulose (5-10 μm in length, 10-20nm in diameter) with a solid content of 1.16% was added to 81.48ml deionized water, and the The rod was fully stirred until there was no obvious agglomeration, and the nanocellulose solution was obtained by ultrasonication for 1 h at 80 Hz in an ice-water bath at 0°C. Add 9.9 g of polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 90% (mol fraction) into the above-mentioned nanocellulose solution, then heat at 90°C, and stir for 4 hours at a speed of 350r / min until a uniform Transparent solution, that is, polyvinyl alcohol / nanocellulose mixed solution; the polyvinyl alcohol / nanocellulose mixed solution is left to defoam for 2 hours, and the solution is cooled to room temperature for later use to ob...

Embodiment 2

[0080] A preparation method of biodegradable high barrier coated paper, comprising the following steps:

[0081] (1) Preparation of polyvinyl alcohol / nanocellulose composite coating: 8.62g of quaternary ammonium salt modified cationic nanocellulose (length 1-10 μm, diameter<20nm) with a solid content of 1.27% was added to 81.48ml deionized water, Stir well with a glass rod until there is no obvious agglomeration, and take 9.8 g of polyvinyl alcohol with a degree of polymerization of 1700 and a degree of alcoholysis of 97% (mole fraction) and add it to the above nanocellulose solution , and then heated at 90°C, and stirred at a speed of 400r / min for 4h until a uniform transparent solution was obtained, that is, the polyvinyl alcohol / nanocellulose mixed solution; the polyvinyl alcohol / nanocellulose mixed solution was left to defoam 2h. Wait for the solution to cool down to room temperature for later use.

[0082] (2) Preparation of cellulose acetate solution: 10g degree of subs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Oxygen transmission rate | aaaaa | aaaaa |

| Water vapor transmission rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com