UV curing adhesive and preparation method thereof

A production method and technology for curing glue, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve problems such as retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

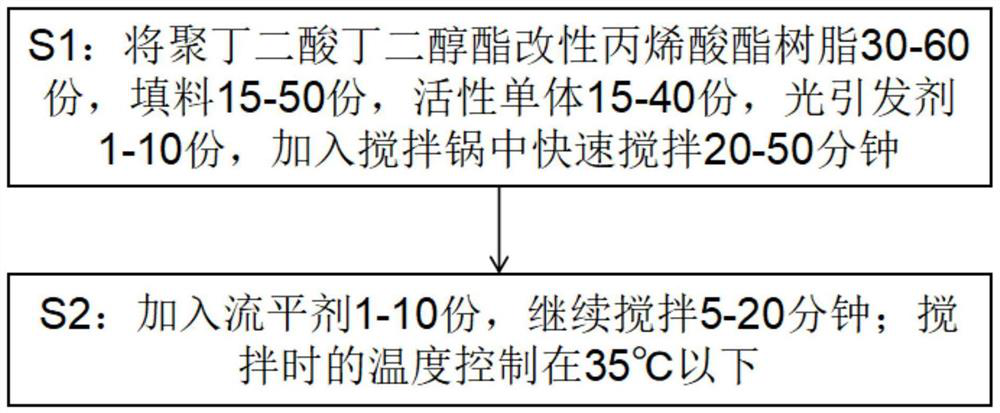

Method used

Image

Examples

experiment example 1

[0058] A kind of UV solid adhesive is prepared by mixing the raw materials in Table 1 parts by weight:

[0059] Raw material mixing ratio of UV-curable adhesive in Table 1 Experimental Example 1

[0060] Polybutylene succinate modified acrylate resin 45 copies VORANOL TM 220-110N Polyol

25 copies Isooctyl acrylate 10 copies Polyethylene glycol (200) diacrylate 14 copies 1-Hydroxycyclohexyl phenyl ketone 3 copies 2,4,6-Trimethylbenzoylphenylphosphonic acid ethyl ester 1 copy EFKA-3777 1 copy Silok-5100 1 copy

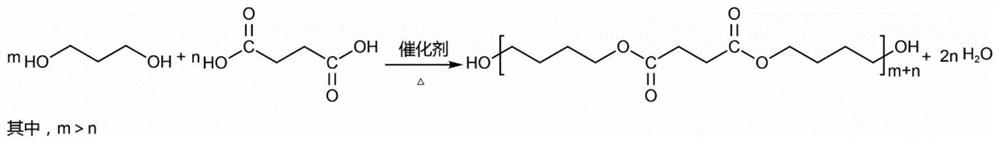

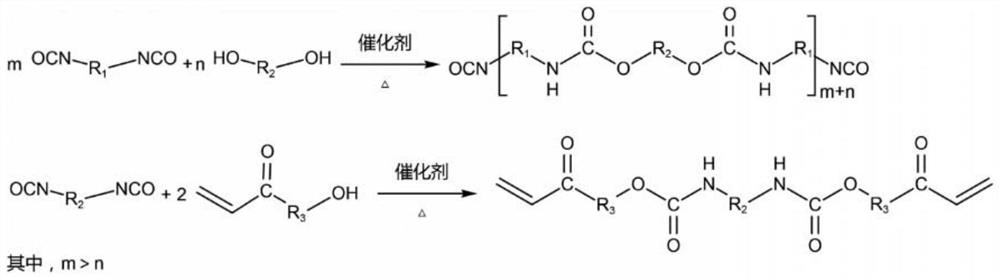

[0061] Wherein, the preparation method of polybutylene succinate modified acrylate resin is:

[0062] Put 100 parts of 1,4-butanediol and 65 parts of succinic acid into the reaction kettle; add 0.05 parts of tetrabutyl titanate under the protection of nitrogen; control the stirring speed at 150-200r / min, heat the oil bath and keep it at 130-160°C, use a vacuum dehydration device to reduce the internal...

experiment example 2

[0067] A kind of UV solid adhesive, is mixed and formulated by the raw material of table 2 parts by weight:

[0068] Raw material mixing ratio of UV-curable adhesive in Table 2 Experimental Example 2

[0069] Polybutylene succinate modified acrylate resin 38 copies WANOL C2010 32 copies Polyethylene glycol (200) diacrylate 16 copies 2-Methyl-2-propenoic acid-3,3,5-trimethylcyclohexyl ester 9.5 servings 1-Hydroxycyclohexyl phenyl ketone 2 copies 2,4,6-Trimethylbenzoylphenylphosphonic acid ethyl ester 1 copy EFKA-3777 1 copy Silok-5100 0.5 parts

[0070] Wherein, the preparation method of polybutylene succinate modified acrylate resin is:

[0071] Put 100 parts of 1,4-butanediol and 65 parts of succinic acid into the reaction kettle; add 0.05 parts of tetrabutyl titanate under the protection of nitrogen; control the stirring speed at 150-200r / min, heat the oil bath and keep it at 130-160°C, use a vacuum dehydratio...

experiment example 3

[0076] A kind of UV solid adhesive is prepared by mixing the raw materials in Table 1 parts by weight:

[0077] Raw material mixing ratio of UV-curable adhesive in Table 3 Experimental Example 3

[0078] Polybutylene succinate modified acrylate resin 49 copies Acetyl tributyl citrate 20 copies Isooctyl acrylate 15 copies 2-(2-Ethoxyethoxy)ethyl acrylate 11 copies 1-Hydroxycyclohexyl phenyl ketone 2 copies 2,4,6-Trimethylbenzoylphenylphosphonic acid ethyl ester 1.5 servings EFKA-3777 0.5 parts Silok-5100 1 copy

[0079] Wherein, the preparation method of polybutylene succinate modified acrylate resin is:

[0080] Put 100 parts of 1,4-butanediol and 65 parts of succinic acid into the reaction kettle; add 0.05 parts of tetrabutyl titanate under the protection of nitrogen; control the stirring speed at 150-200r / min, heat the oil bath and keep it at 130-160°C, use a vacuum dehydration device to reduce the internal pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com