Special agent for plant fiber product polymerization and preparation method thereof

A plant fiber and special agent technology, which is applied in the field of composite materials and plant fiber materials, can solve the problems of not easy to degrade, heavy weight, natural ecological environment pressure and damage, etc., to increase soil fertility, strong compressive performance, and reduce weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

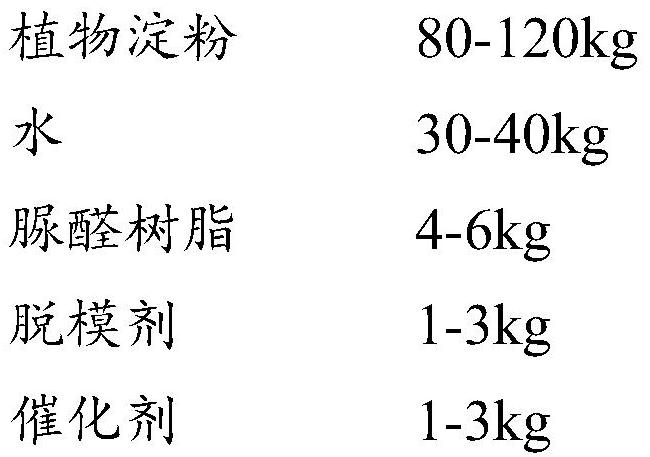

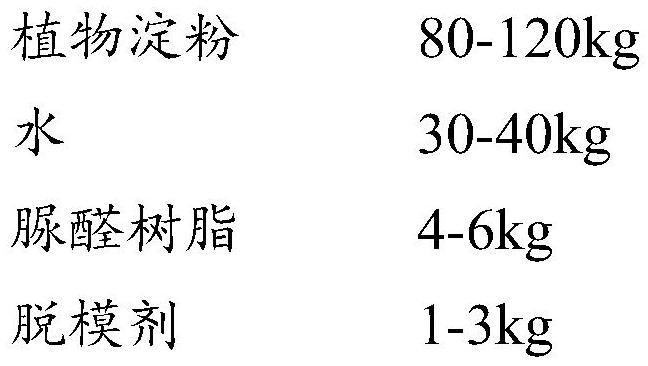

Embodiment 1

[0019] When preparing, take 80kg of plant starch; 30kg of water; 4kg of urea-formaldehyde resin; put them into the mixing tank in turn, stir until uniform, and cool and discharge; then add 1kg of release agent; Put the raw materials into the grinder, grind to 500-1000 mesh level, and then discharge.

Embodiment 2

[0021] When preparing, take 80kg of plant starch; 30kg of water; 5kg of urea-formaldehyde resin; put them into the mixing tank in turn, fully stir until uniform, and cool and discharge; then add 2kg of release agent; Put the raw materials into the grinder, grind to 500-1000 mesh level, and then discharge.

Embodiment 3

[0023] When preparing, take 120kg of plant starch; 30kg of water; 5kg of urea-formaldehyde resin; put them into the mixing tank in turn, fully stir until uniform, and cool and discharge; then add 2kg of mold release agent; Put the raw materials into the grinder, grind to 500-1000 mesh level, and then discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com