Super-clear flexible glass protection film, preparation method and application thereof

A glass protective film, flexible glass technology, applied in branch equipment, film/sheet release coating, film/sheet adhesive, etc., can solve the problems of easy product snowflakes and bubbles, high scrap rate, high hardness , to solve the effect of laminating bubbles and snowflakes, high production yield, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

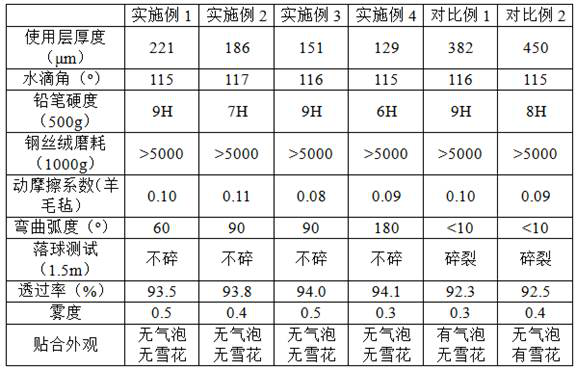

Embodiment 1

[0063] An ultra-clear and high-hardness flexible glass protective film is made by the following steps:

[0064] Step S1: mix polyurethane-modified acrylic resin, epoxy-modified acrylic resin, fluorine-modified polyurethane resin, photoinitiator, ethyl acetate, acetone, methyl ethyl ketone, and toluene in mass ratio: 25:10:2:0.5: 15:10:5:10, stir and mix evenly, coat on the A side of the second PET layer, enter the high-temperature oven, and set the temperature of the oven in different zones. The temperature is: 40℃, 60℃, 90℃, 120℃, 100℃, It goes out of the oven and enters into a UV curing device, where it is cured into the first polyurethane acrylic coating, and the semi-finished product A1 is obtained by winding. The thickness of the second PET layer is 125 μm, the thickness of the first polyurethane acrylic coating is 35 μm, and the thickness of semi-finished product A1 is 160 μm.

[0065] Step S2: Stir and mix polyurethane-modified acrylic resin, photoinitiator, ethyl acet...

Embodiment 2

[0072]Step S1: mix polyurethane-modified acrylic resin, epoxy-modified acrylic resin, fluorine-modified polyurethane resin, photoinitiator, ethyl acetate, acetone, methyl ethyl ketone, and toluene in mass ratio: 30:10:2:0.5: 15:15:5:10, stir and mix evenly, coat on the A side of the second PET layer, enter the high-temperature oven, and set the temperature of the oven in different zones, the temperature is: 40°C, 60°C, 90°C, 120°C, 100°C It goes out of the oven and enters into a UV curing device, where it is cured into the first polyurethane acrylic coating, and the semi-finished product A1 is obtained by winding. The thickness of the second PET layer is 75 μm, the thickness of the first polyurethane acrylic coating is 45 μm, and the thickness of semi-finished product A1 is 120 μm.

[0073] Step S2: Stir and mix polyurethane-modified acrylic resin, photoinitiator, ethyl acetate, acetone, butanone according to mass ratio: 35:0.5:15:10:10, and coat them in step S1 semi-finished ...

Embodiment 3

[0080] Step S1: Mix polyurethane-modified acrylic resin, epoxy-modified acrylic resin, fluorine-modified polyurethane resin, photoinitiator, ethyl acetate, acetone, methyl ethyl ketone, and toluene in mass ratio: 30:5:1.5:0.6: 15:15:5:10, stir and mix evenly, coat on the A side of the second PET layer, enter the high-temperature oven, and set the temperature of the oven in different zones, the temperature is: 40°C, 60°C, 90°C, 120°C, 100°C It goes out of the oven and enters into a UV curing device, where it is cured into the first polyurethane acrylic coating, and the semi-finished product A1 is obtained by winding. The thickness of the second PET layer is 50 μm, the thickness of the first polyurethane acrylic coating is 45 μm, and the thickness of semi-finished product A1 is 95 μm.

[0081] Step S2: Stir and mix polyurethane-modified acrylic resin, photoinitiator, ethyl acetate, acetone, butanone according to mass ratio: 35:0.5:15:10:10, and coat them in step S1 semi-finished...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com