Graphene polyurethane composite sponge material as well as preparation method and application thereof

A composite sponge and polyurethane technology, applied in the field of graphene-polyurethane composite sponge material and its preparation, can solve the problems of complex preparation process, poor adsorption capacity, narrow application field, etc., and achieves strong adsorption effect, easy industrialized implementation, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

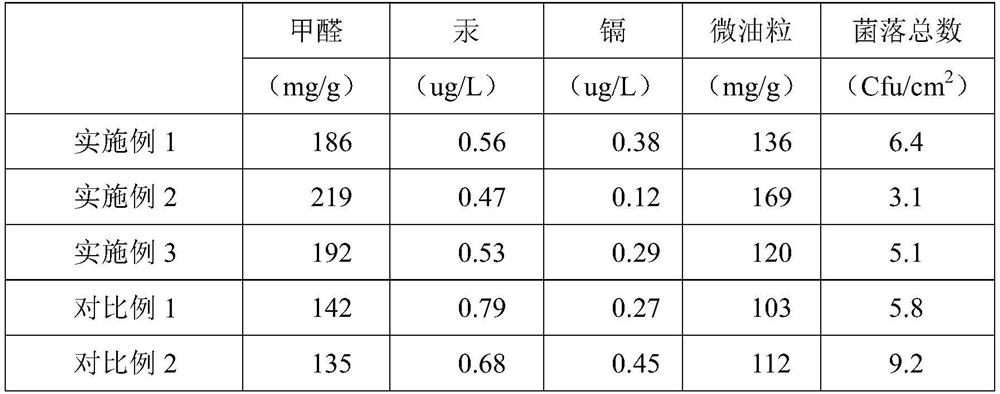

Examples

preparation example Construction

[0023] The invention provides a kind of preparation method of graphene polyurethane composite sponge material, comprises the following steps:

[0024] a. Weigh each raw material according to the following weight percentages, 0.05-0.14% of stannous octoate, 0.09-0.26% of triethylenediamine, 0.19-0.55% of mercaptoethanol, 0.20-0.60% of silicon-containing surfactant, and 0.50-0.50% of graphene oxide 2.00%, water 0.90-2.70%, 1,4-butanediol 1.67-5.01%, toluene diisocyanate 13.70-41.11%, polyether polyol 46.74-86.81%;

[0025] b. Ultrasonic dispersion of graphene oxide in water and 1,4-butanediol solution for 20-35 minutes to make it evenly dispersed and obtain GO dispersion;

[0026] c. Add mercaptoethanol to the GO dispersion and stir magnetically at 85-90°C for 30-35 minutes to obtain a modified GO dispersion;

[0027] d. Add polyether polyol to the modified GO dispersion, stir to disperse evenly, then add silicon-containing surfactant and stir until milky white, then add stanno...

Embodiment 1

[0037] Embodiment 1 adopts the inventive method to prepare graphene to filter polyurethane composite sponge material

[0038] The specific operation steps are as follows:

[0039] (1) The preparation raw materials include the following parts according to the mass percentage

[0040] Stannous octoate 0.09%

[0041] Triethylenediamine 0.17%

[0042] Mercaptoethanol 0.32%

[0043] Silicone Surfactant 0.40%

[0045] Water 1.78%

[0046] 1,4 Butanediol 3.29%

[0047] Toluene diisocyanate 27.03%

[0048] Polyether polyol 65.85%;

[0049] (2) Graphene oxide is ultrasonically dispersed in water and 1,4-butanediol solution for 20 minutes to make it evenly dispersed to obtain a GO dispersion;

[0050] (3) Add mercaptoethanol to the GO dispersion and stir magnetically at 85°C for 30 min to obtain the modified GO dispersion.

[0051] (4) Add polyether polyol SEP~560D to GO dispersion, mechanically stir to disperse evenly, then add silicon-containing...

Embodiment 2

[0053] Embodiment 2 adopts the inventive method to prepare graphene to filter polyurethane composite sponge material

[0054] Graphene filters the preparation method of polyurethane composite sponge material, comprises the steps:

[0055] The only difference from Example 1 is that the proportion of graphene oxide is 0.50%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com