Preparation method of electro-catalytic material VS2 for ENRR

A technology of electrocatalysis and vanadium disulfide, applied in chemical instruments and methods, electrodes, vanadium compounds, etc., can solve the problems of difficult unification of physical characteristics of materials, long reaction time, etc., and achieve the effect of concentrated size distribution and shortened time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following will be further described in detail through specific embodiments, but the present invention is not limited to the following examples.

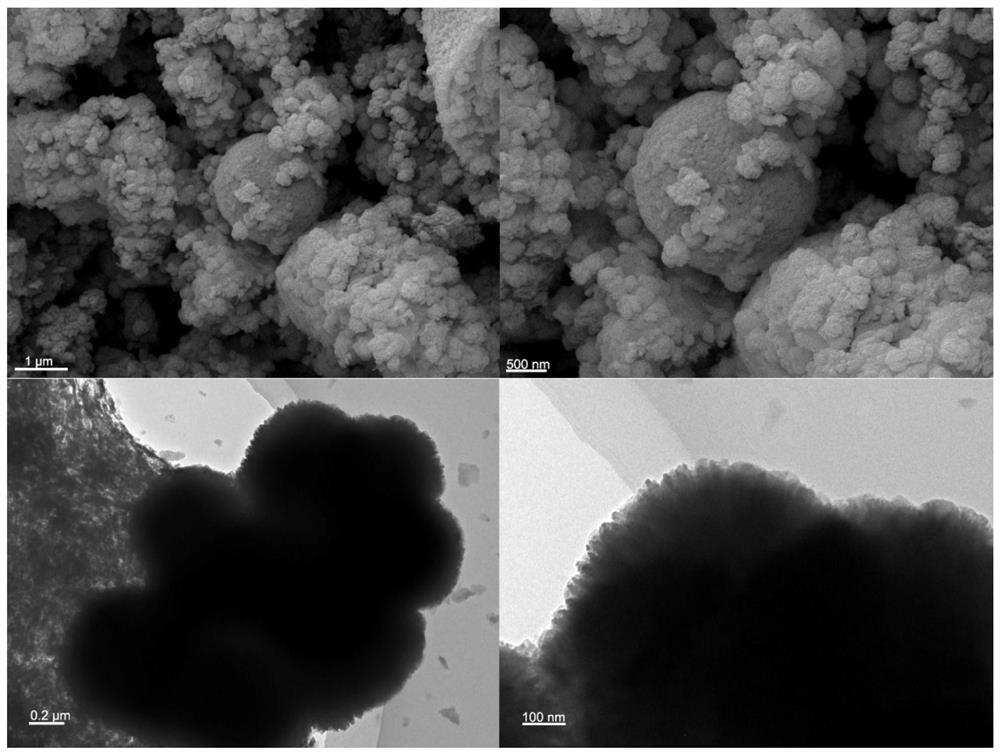

[0020] combine figure 1 As shown, an electrocatalytic material VS for ENRR 2 , the material is mainly composed of microspheres with a particle size of about 1 μm.

[0021] Preparation method: Mix 3 mmol of ammonium metavanadate, 15 mmol of thioacetamide and 40 mL of ultrapure water, and stir magnetically for 1 hour to obtain a light green turbid liquid. The above liquid was transferred to a microwave reactor, and the hydrothermal synthesis was carried out according to the following process: heating from room temperature to 120°C for 10 minutes, and keeping at this temperature for 8 minutes; then heating to 150°C for 10 minutes, and keeping at this temperature for 8 minutes; then 10 minutes Heated to 180°C, and kept at this temperature for 120min; finally cooled naturally to room temperature. The power used in the microw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com