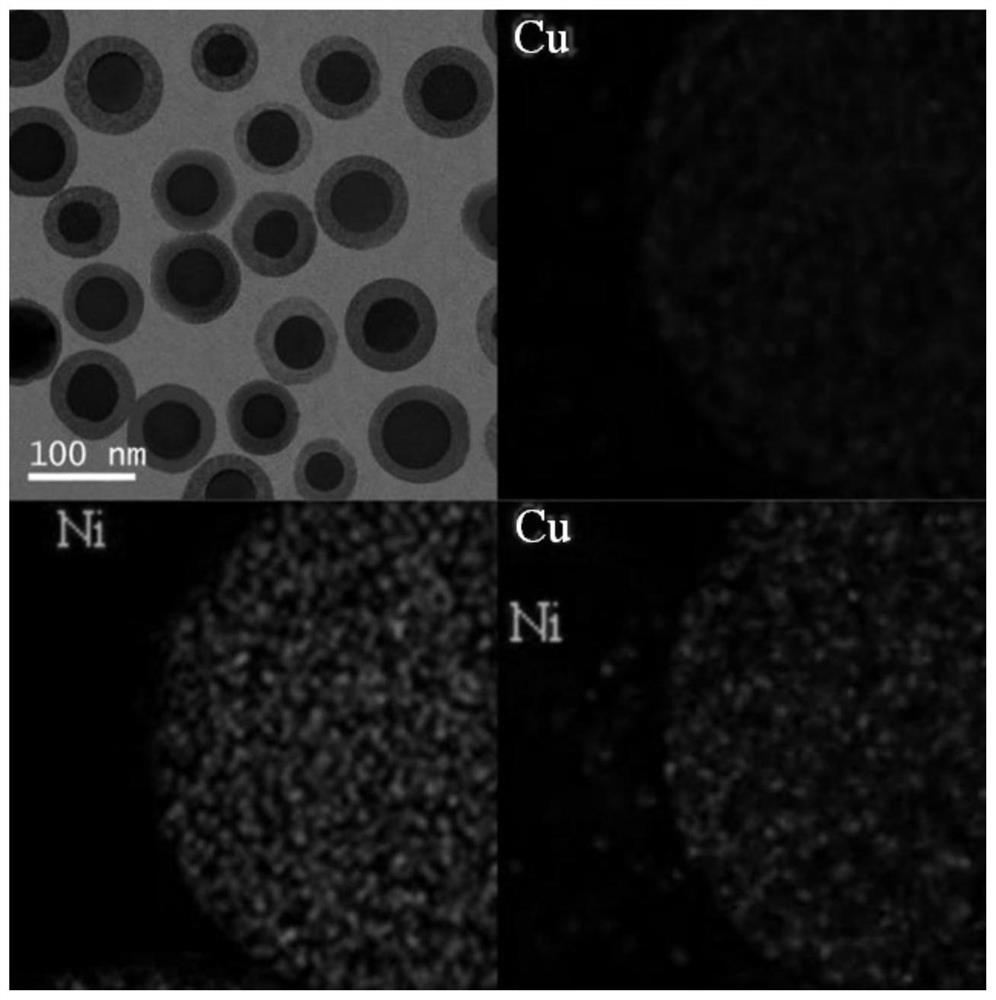

Nano hierarchical pore SiO2@Cu/Ni core-shell material as well as preparation method and application thereof

A multi-level porous, nano-level technology, applied in catalyst activation/preparation, nanotechnology, nanotechnology, etc., can solve the problems of high preparation cost and poor stability of precious metal active centers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A Nanoscale Hierarchical Porous SiO 2 The preparation method of @Cu / Ni core-shell material, comprises the following steps:

[0034] 1) Mix ethyl orthosilicate and ethanol at a volume ratio of 1:(30-40) and prepare a tetraethyl orthosilicate solution, mix ammonia water and water at a volume ratio of 1:(6-6.5) and prepare to obtain ammonia aqueous solution;

[0035] 2) Mix ethyl orthosilicate solution with ammonia solution and stir at 20-30°C for 20-28h, then centrifuge, and wash the solid product obtained by centrifugation until neutral, then dry at 100-120°C for 10 -12h, and then calcined at 545-555°C for 4-7h to obtain nano-scale spherical SiO 2 ; Wherein, the volume ratio between the ethyl orthosilicate in the ethyl orthosilicate solution and the ammonia in the ammonia solution is 1:(0.5-1.5);

[0036] 3) Nanoscale spherical SiO 2 Mix with water at a mass volume ratio of 0.18-0.23g / 65mL to prepare a dispersion, and then mix the dispersion with (0.048-0.052)mol·L ...

Embodiment 1

[0042] A Nanoscale Hierarchical Porous SiO 2 The preparation method of @Cu / Ni core-shell material, comprises the following steps:

[0043] 1) Mix 4mL tetraethyl orthosilicate with 140mL ethanol to obtain tetraethyl orthosilicate solution; mix 4mL ammonia water with 25mL water to obtain ammonia solution;

[0044] 2) Mix ethyl tetrasilicate solution with ammonia solution and stir at 25°C for 24h, then centrifuge, and wash the solid product obtained by centrifugation to neutrality, then dry at 110°C for 12h, and then place in a tube furnace Medium to 2°C·min -1 The heating rate was heated to 550 ° C, and the constant temperature was calcined for 5 hours to obtain nano-scale spherical SiO 2 ;

[0045] 3) 0.2g nanoscale spherical SiO 2 Add to 65mL water and ultrasonically disperse evenly to get SiO 2 Dispersions;

[0046] 4) to SiO 2 Add 7.2mL 0.05mol L to the dispersion -1 CuSO 4 ·5H 2 O solution, after stirring at 30°C for 1 hour, add 0.12g reducing agent iron powder, a...

Embodiment 2

[0051] In this embodiment, SiO prepared in Example 1 2 @Cu / Ni core-shell material is used as a desulfurization catalyst to catalyze the C-S bond breaking reaction of 4,6-dimethyldibenzothiophene. The specific experimental process is as follows:

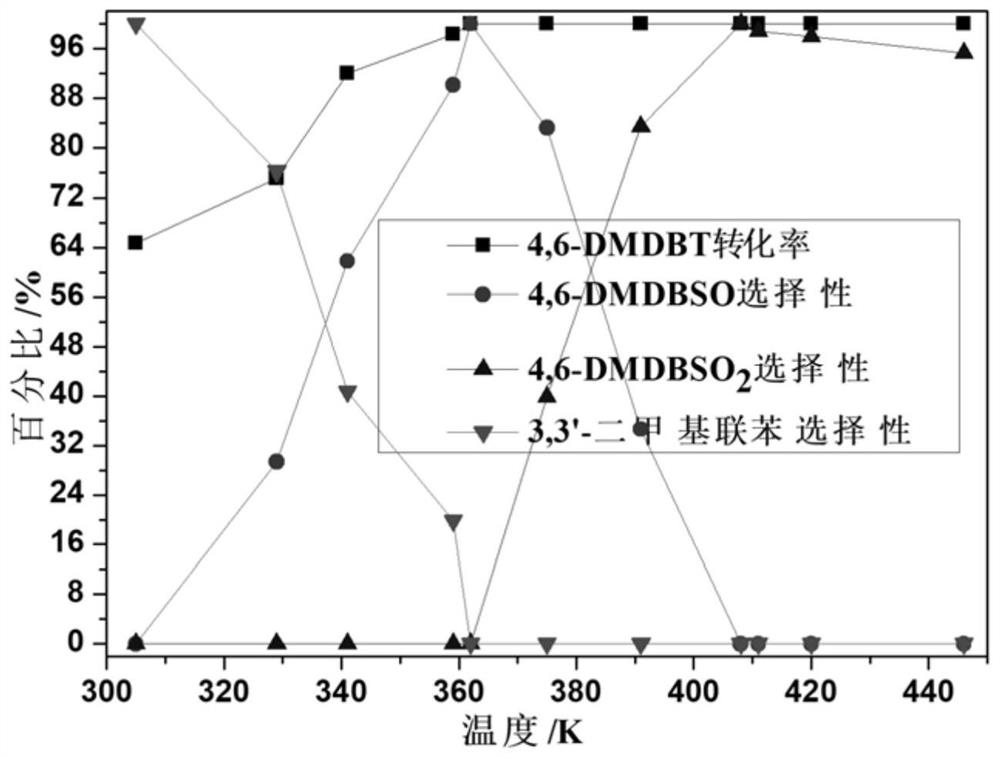

[0052] The reaction activity test of the catalyst was carried out in a fixed-bed reactor, and the dosage of the catalyst was 20 mg. Before the desulfurization reaction, the catalyst was heated in 800 °C H 2 Reduction in the atmosphere for 3h, so that the Cu center in the catalyst is replaced by Cu 2 Exist in the form of O, then cool to room temperature, will contain 1% methanol, 1% H 2 o 2 , 5% 4,6-DMDBT benzene solution mixture is introduced into the preheater, then flows into the reactor containing the catalyst, and stays at a specific reaction temperature for 65min. The experimental results are as follows figure 2 shown. From figure 2 It can be seen that even under mild conditions, the desulfurization rate and selectivity o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com