Vacuum nano waterproof breathable fabric and application thereof

A waterproof and breathable fabric, nano technology, applied in the field of fabrics, can solve the problems of poor waterproof and moisture permeability, reduced market share, drape, breathability, softness, fit and lightness loss, etc., to increase the breathability function, Increase antistatic effect, increase water repellency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

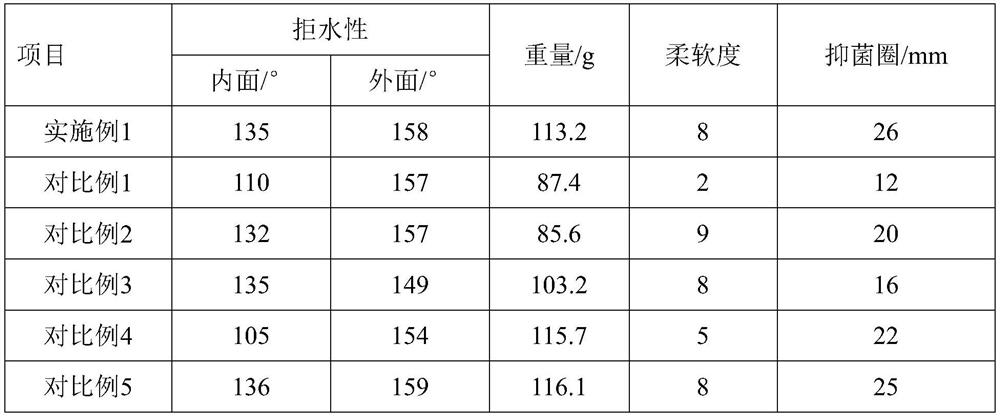

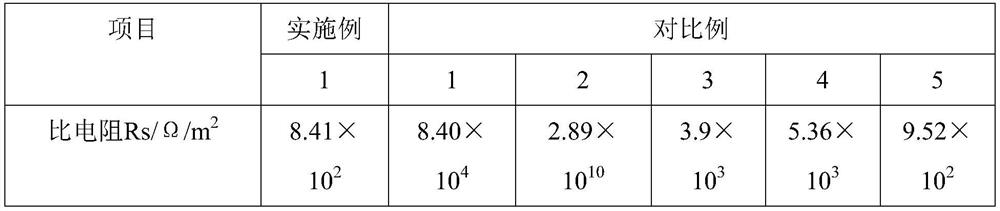

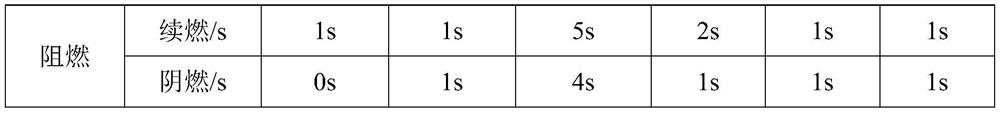

Examples

Embodiment 1

[0023] In this embodiment, a vacuum nano-waterproof and breathable fabric includes a built-in layer, a fabric substrate, a nano-waterproof layer, and a nano-water-repellent coating from the inside to the outside. The built-in layer and the nano-waterproof layer are respectively laminated on both sides of the fabric substrate by hot pressing. , the nano-water-repellent coating adopts vacuum nano-coating to deposit a thin film on the nano-water-proof layer;

[0024] The fabric base material is one of polypropylene fiber, polyester fiber and regenerated fiber.

[0025] The preparation steps of the vacuum nanometer waterproof breathable fabric are as follows:

[0026] (1) Preparation of built-in layer

[0027] a. Pickle the common polyimide fiber with salicylic acid with concentration percentage of 10-15% for 20-30min, then remove and drain and impregnate with ammonium chloride with concentration percentage of 2-5% for 20-30min , take it out and drain it, put it into a continuou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com