A stress-relieving high-speed rail car group manufacturing body leveling device

A technology for stress relief and leveling devices, which is applied in the direction of feeding devices, manufacturing tools, positioning devices, etc., to achieve the effects of avoiding dimensional deviation, improving the flexibility of use, and improving the cleaning range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

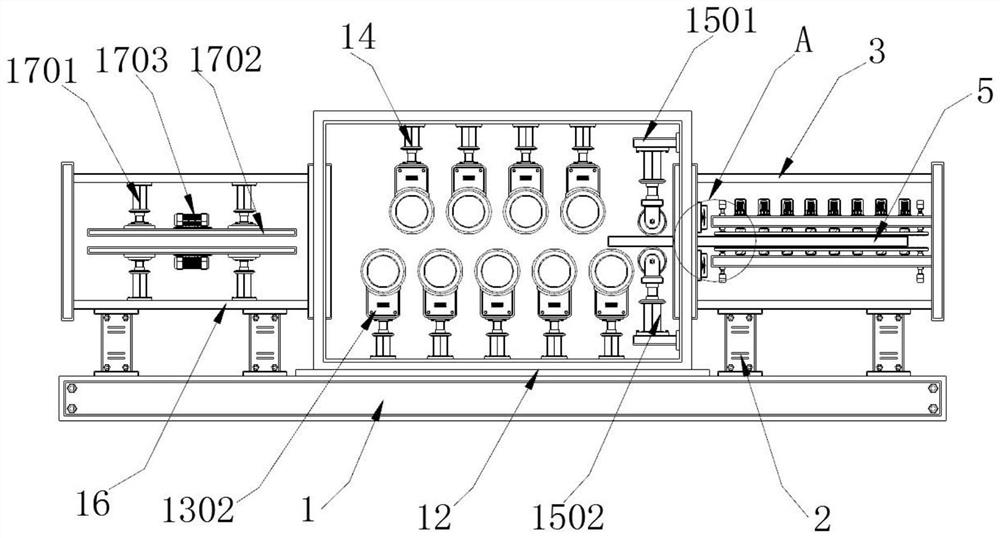

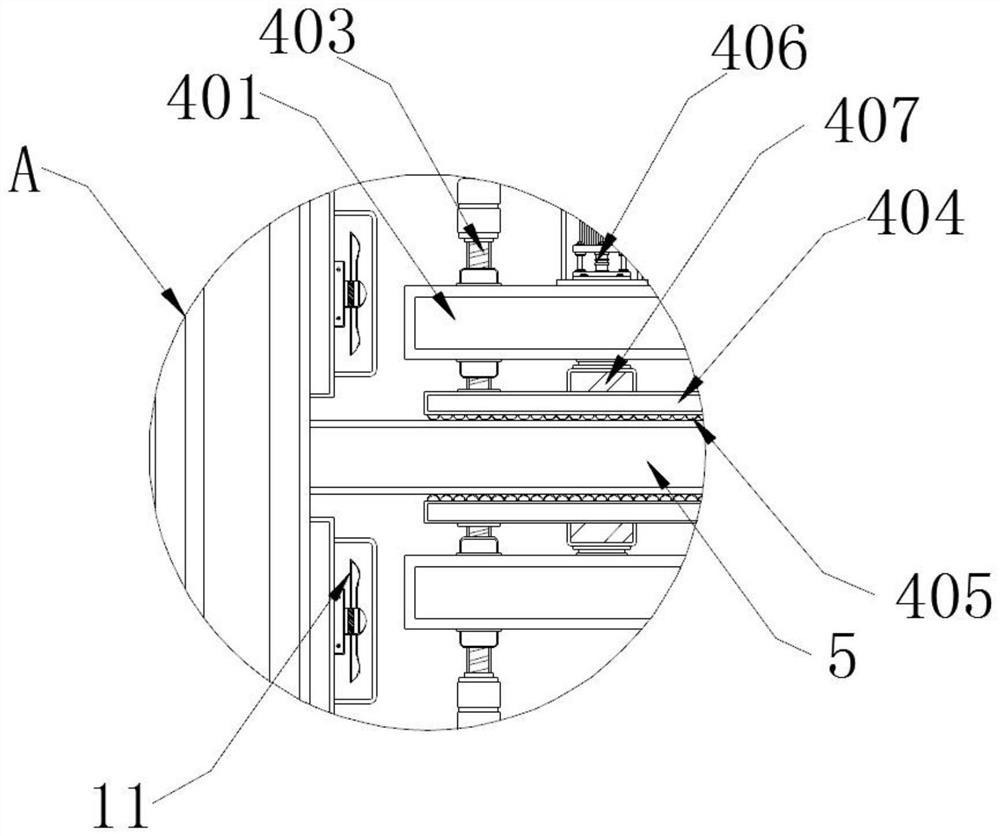

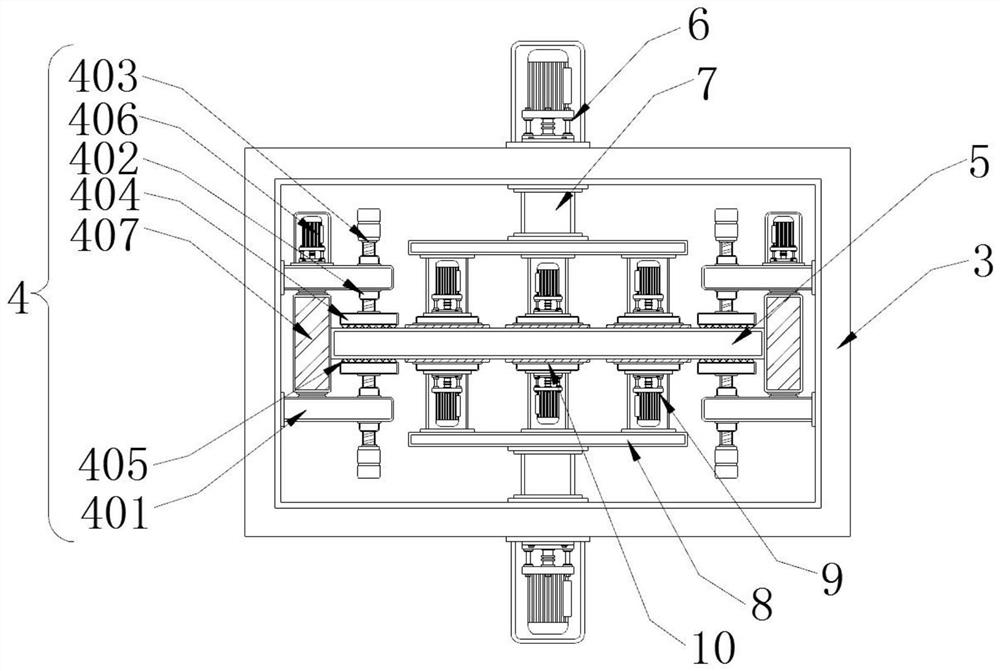

[0030] see Figure 1-8, the present invention provides a technical solution: a stress-relieving high-speed rail vehicle group manufacturing body leveling device, comprising a base 1, a lower leveling component 13 and a stress-relieving component 17, the top of the base 1 is provided with support seats 2 on both sides, and The top right side of the support base 2 is provided with a feeding box 3 , the inner two sides of the feeding box 3 are connected with a limit push assembly 4 , and the inner side of the limit push assembly 4 is arranged with a steel plate 5 of the vehicle group, and the middle end of the top of the base 1 is A leveling box 12 is provided, the lower leveling assembly 13 is arranged on the inner side of the bottom of the leveling box 12 , and the lower leveling assembly 13 includes a second hydraulic cylinder 1301 , a fixed seat 1302 , a driving gear 1303 , a fourth motor 1304 , and a fixed cylinder 1305 , the driven gear 1306, the power transmission shaft 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com