Cloth breaking machine for spinning

A cloth breaking machine and table top technology, which is used in textiles and papermaking, textile material cutting, metal processing, etc., can solve the problems of no heating jacket, no cylinder, no clamping device, etc., so as to solve the problem of freezing fingers. And the effect of frostbite, improve work efficiency, reduce cost and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

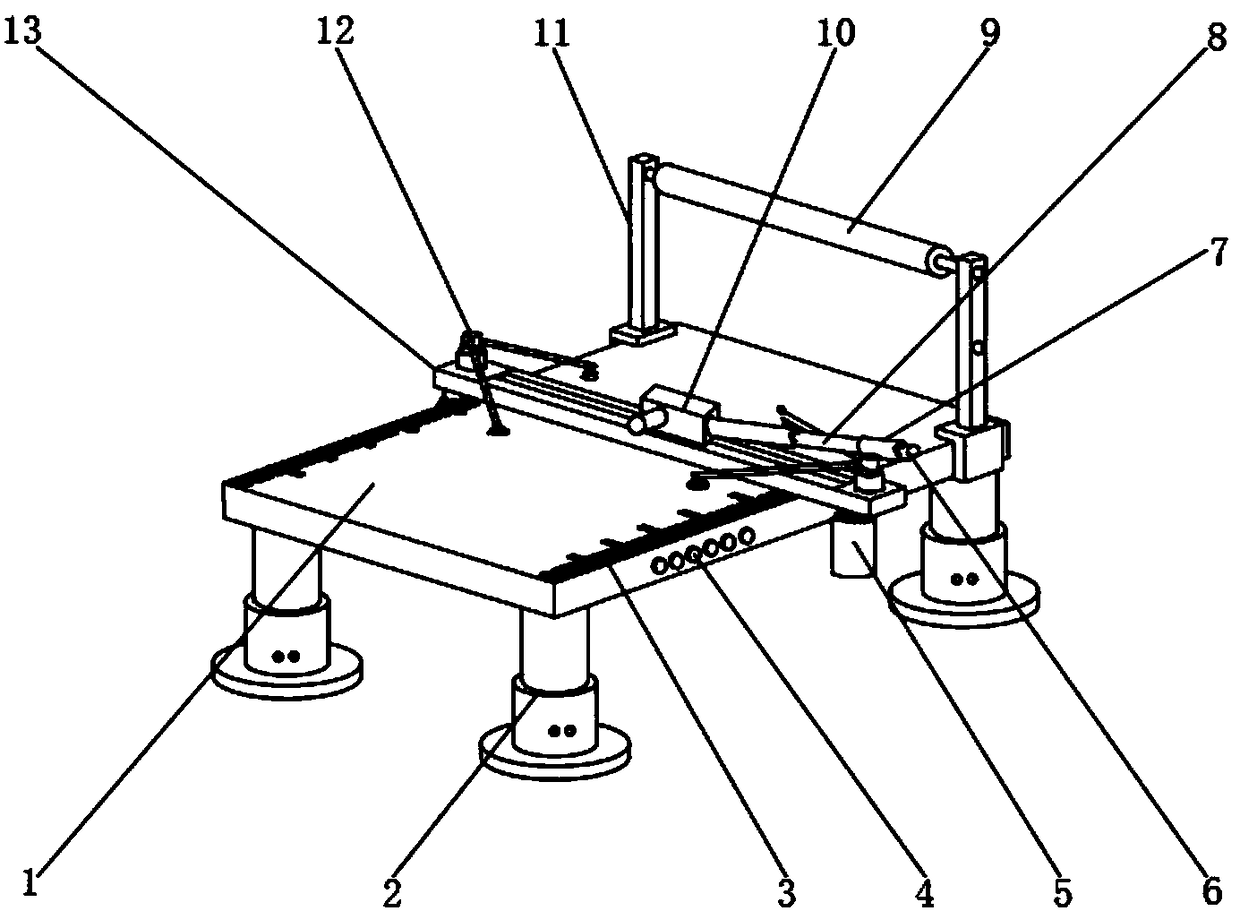

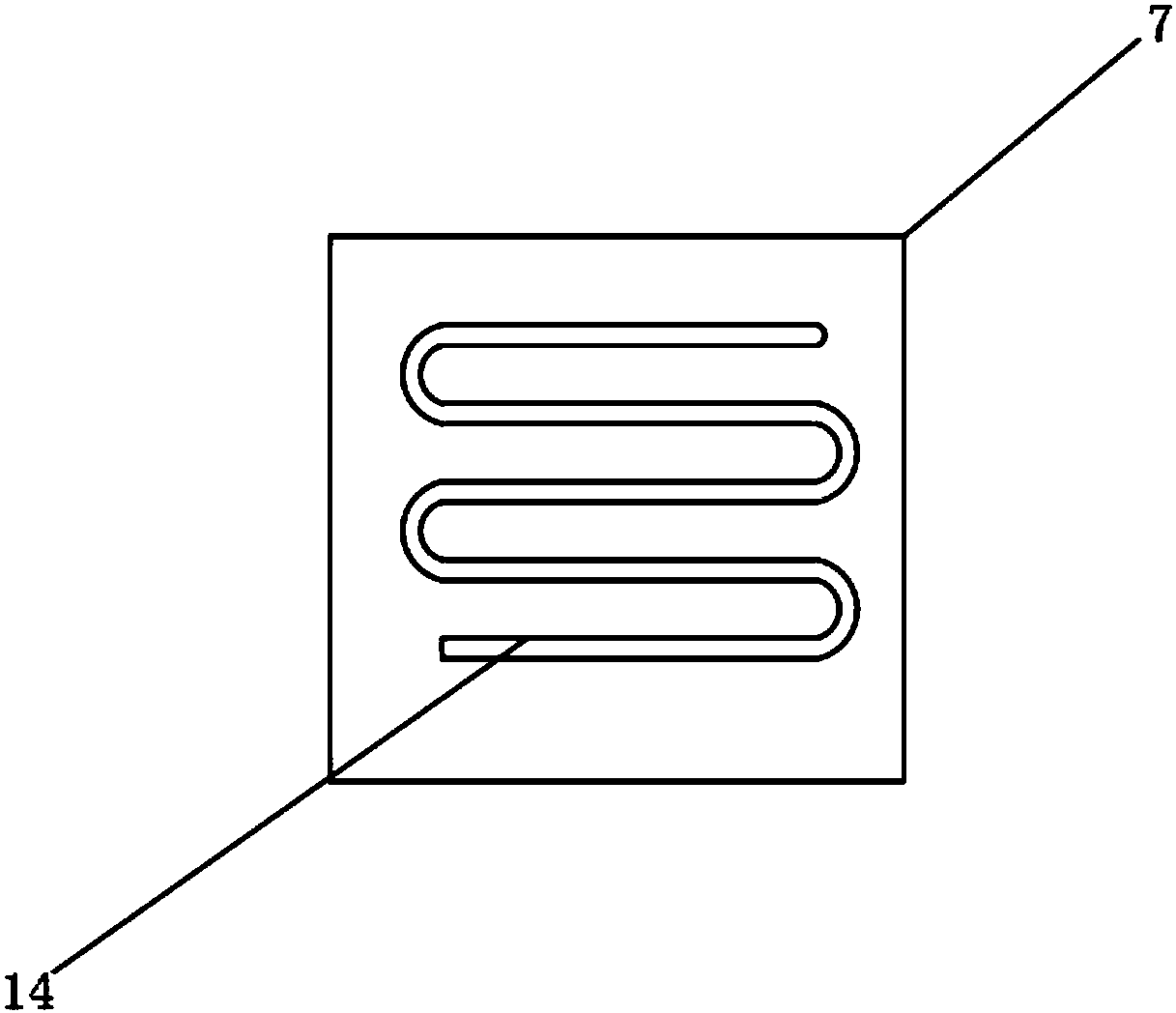

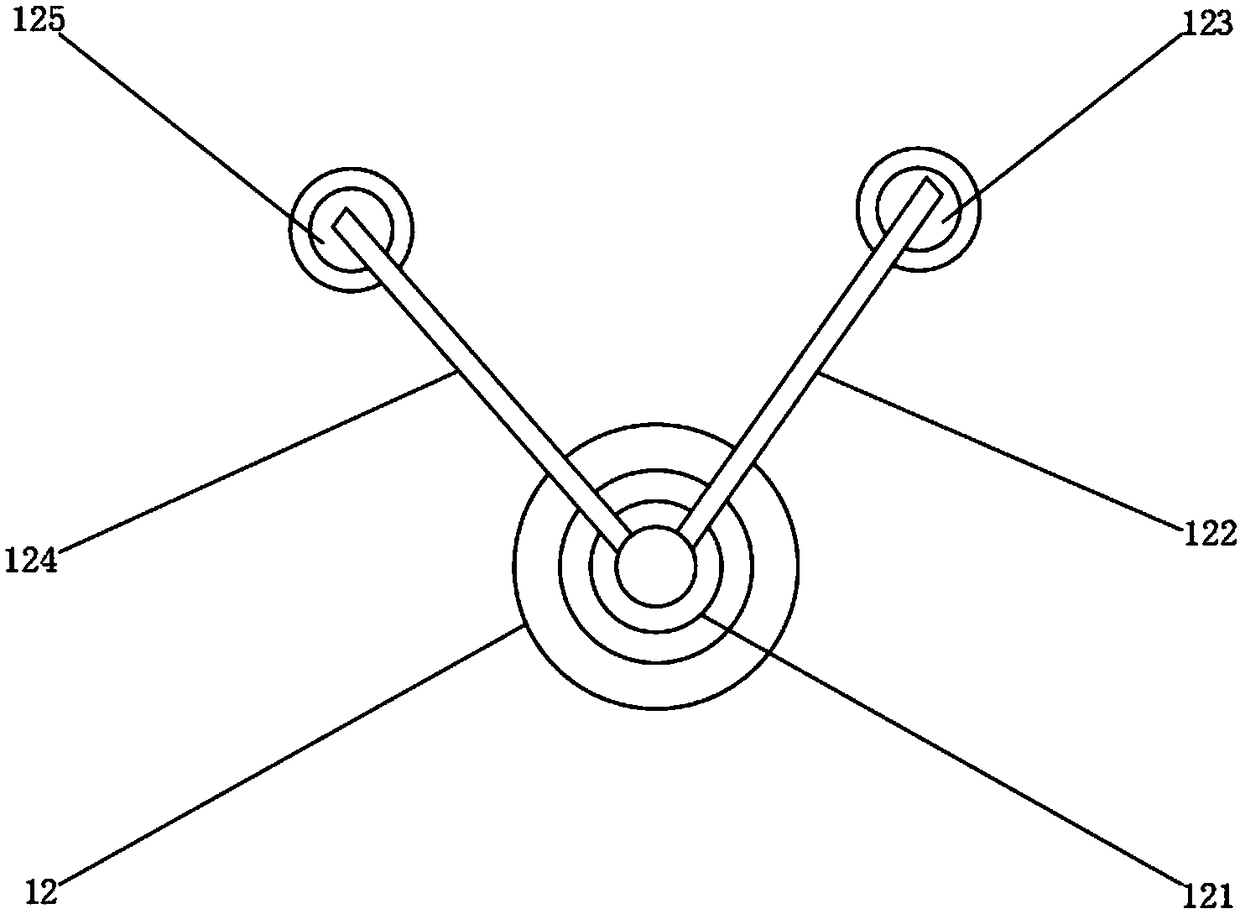

[0020] Example: such as Figure 1-3 As shown, the present invention provides a technical solution, a fabric cutting machine for textiles, comprising a table top 1, a cylinder 2 is installed at the bottom of the table top 1, and a scale scale 3 is arranged on the surface of the table top 1, and the top of the table top 1 is close to the scale scale 3 A cutting slide 13 is provided at one side of the table, and a column 11 is provided at a position above the table 1 near the side of the cutting slide 13, a control switch 4 is embedded and installed on one side of the table 1, and one side of the table 1 A first electric telescopic rod 5 is provided at a position close to the control switch 4, the upper ends of the cutting slide 13 are provided with clamping devices 12, and the cutting slide 13 is provided with a cutting device 10, and a cutting device 10 A telescopic rod 8 is connected to one side of the telescopic rod 8, a handle 6 is provided at one end of the telescopic rod 8,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com