Comb fitting for a combing machine

A technology for carding cloth and combing machine, applied in the direction of combing machine, fiber processing, textile and papermaking, etc., can solve the problems of increasing manufacturing error, high manufacturing cost, time-consuming and other problems, avoiding dimensional deviation, reducing The effect of a single length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

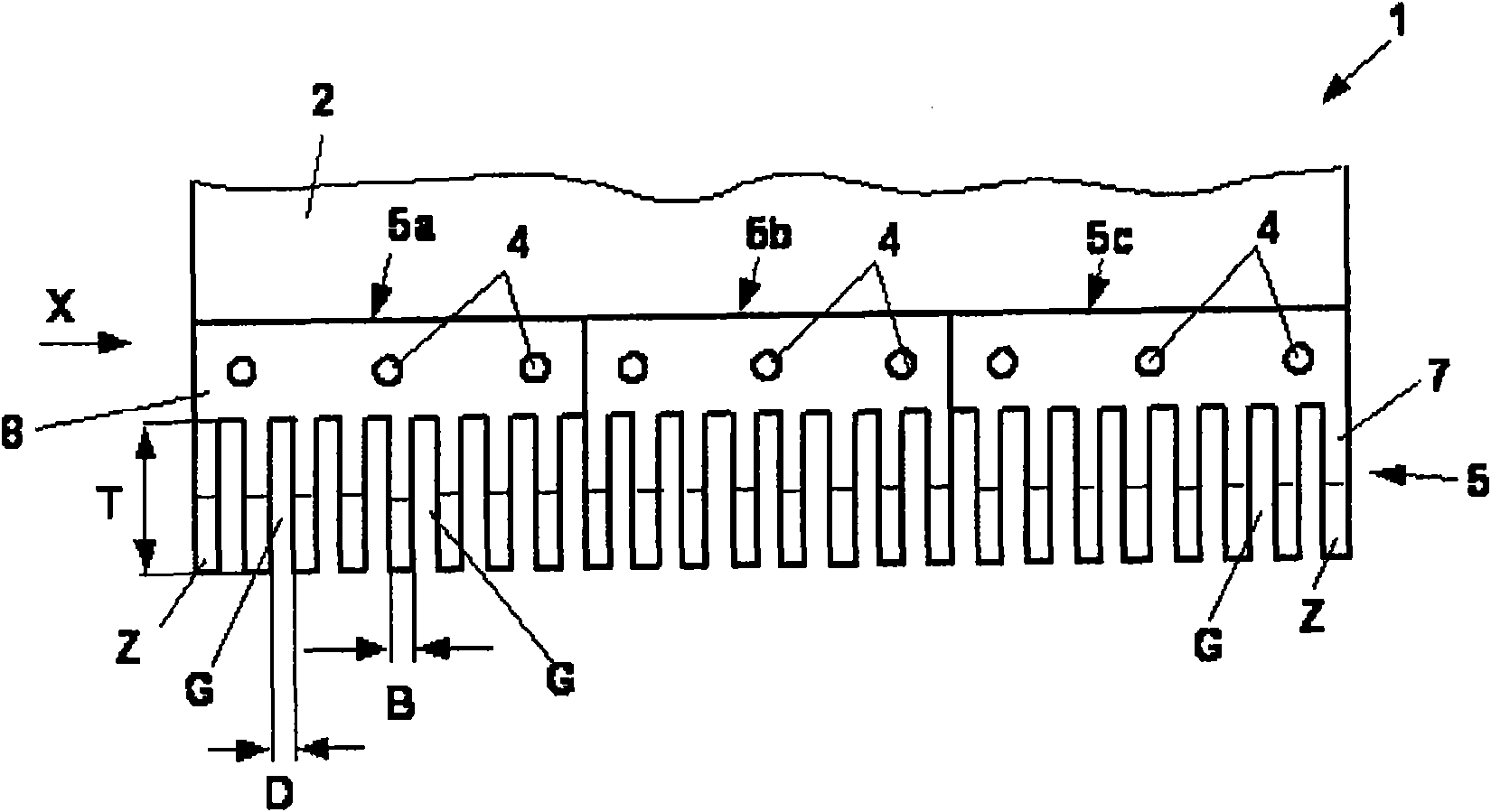

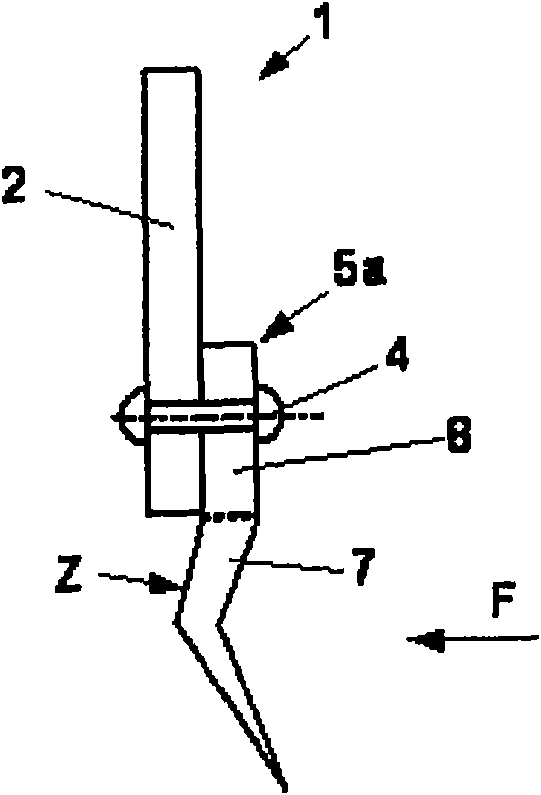

[0029] figure 1 Shows a partial view of a fixed comb 1 of a combing machine in figure 2 is shown in side view X. The fixed comb is positioned between a pair of detaching rollers and the front end of the lower nipper of the clamp assembly in its installed position, as can be seen, for example, from the published patent document DE19736582A1 figure 1 seen in.

[0030] Illustration of the fixed comb holder is omitted in this exemplary embodiment. Only frame 2 (plate) is shown, which is connected to a fixed comb holder (not shown) and to which card cloth 6 is fastened by rivets 4 . The card cloth can also be fastened to the frame 2 by other fastening means, for example by screws, or glued or welded to the frame.

[0031] as available from figure 1 It further follows that in this embodiment the carding cloths comprise three carding cloths 5a to 5c which are placed adjacent to each other and in each case of a row of teeth Z (needles) placed adjacent to each other by a rivet 4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com