Cab hood of maglev vehicle and manufacturing method thereof

A manufacturing method and magnetic levitation technology, which is applied to the driver's cab hood of magnetic levitation vehicles and its manufacturing field, can solve the problems of difficult control of product weight deviation, unfavorable light weight of rail traffic, and large changes in product local dimensions, and achieve a significant lightweight effect , product thickness reduction, and the effect of reducing the difference in thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

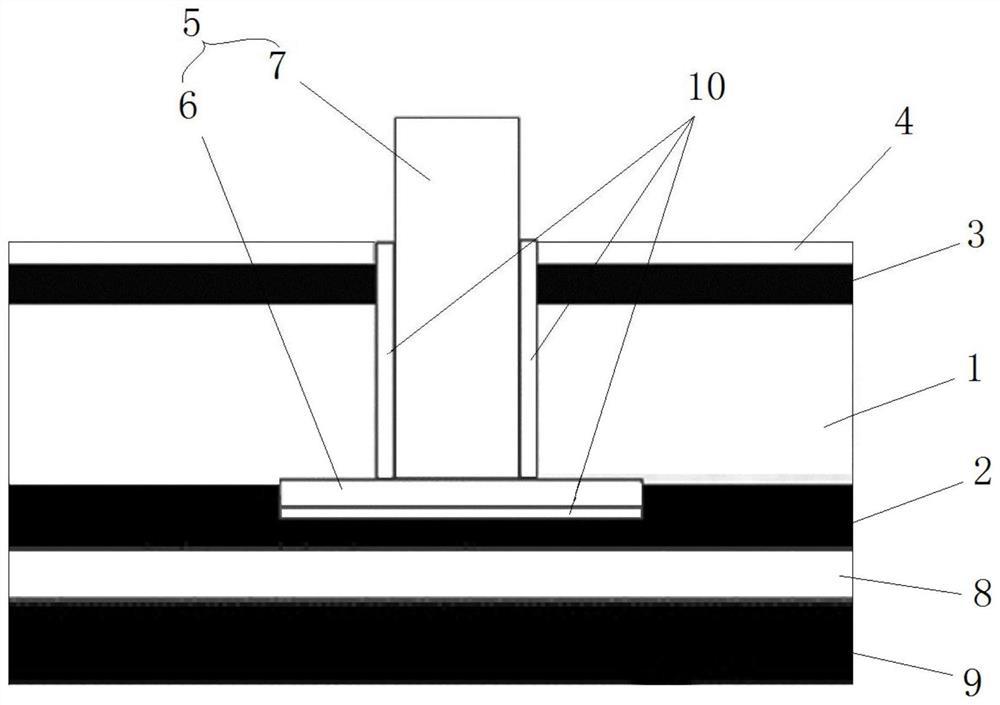

[0040] This embodiment provides a specific implementation of the driver's cab hood of a magnetic levitation vehicle, such as figure 1 As shown, it includes: a hood body, the hood body has a foam sandwich layer 1 and a buffer layer arranged on the upper surface and the lower surface of the foam sandwich layer 1, the buffer layer mainly adopts carbon fiber prepreg, specifically Yes, the buffer layer uses 50K tow carbon fiber prepreg.

[0041] On the upper surface of the buffer layer located on the upper surface of the foam sandwich layer 1 of the hood body, a sound-insulating layer 4 is also provided, and the sound-insulating layer 4 is made of sound-insulating and damping material.

[0042] The metal piece 5 on the hood body is embedded in the foam sandwich layer 1 and the buffer layer, and one end of the metal piece 5 protrudes from the outside of the hood body. The part of the metal part 5 embedded in the foam sandwich layer 1 and the buffer layer is respectively connected w...

Embodiment 2

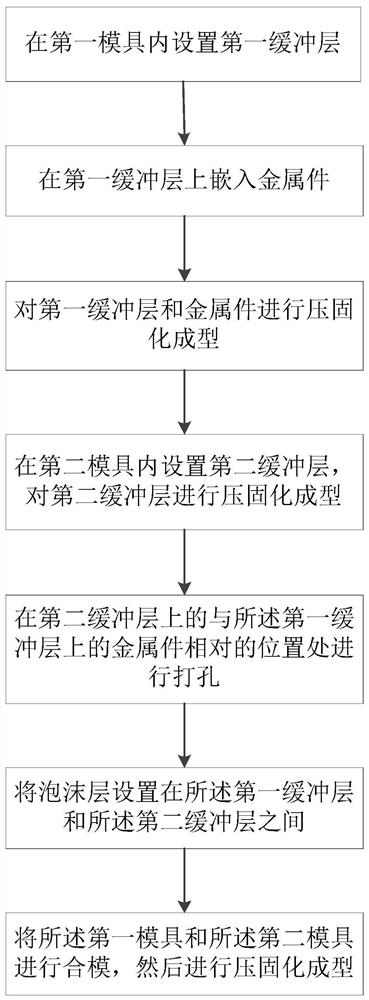

[0047] This embodiment provides a specific embodiment of the manufacturing method of the driver's cab hood of the magnetic levitation vehicle described in Embodiment 1, as figure 2 shown, including the following steps:

[0048] First, cut prepreg and foam are supplied.

[0049] In the second step, the surface layer 9, the impact-resistant layer 8 and the first cushioning layer 2 are sequentially laid in the lower mold.

[0050] The third step is to embed the metal part 5 on the first buffer layer 2 and apply glue;

[0051] In the fourth step, the surface layer 9, the impact-resistant layer 8, the first buffer layer 2 and the metal part 5 are vacuum-bag-cured and molded into a semi-finished product A;

[0052] The fifth step is to lay the second buffer layer 3 in the upper mold, and punch holes on the second buffer layer 3. The specific punching position is: the position opposite to the metal piece 5 on the first buffer layer 2 ;

[0053] In the sixth step, the second buff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com