Production method for tire cord steel

A production method and technology for cord steel, which are applied to workpiece surface treatment equipment, metal rolling, manufacturing tools, etc., can solve the problems of affecting production rhythm, excessive residues, and high wire breakage rate, and achieve the effect of easy peeling and removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

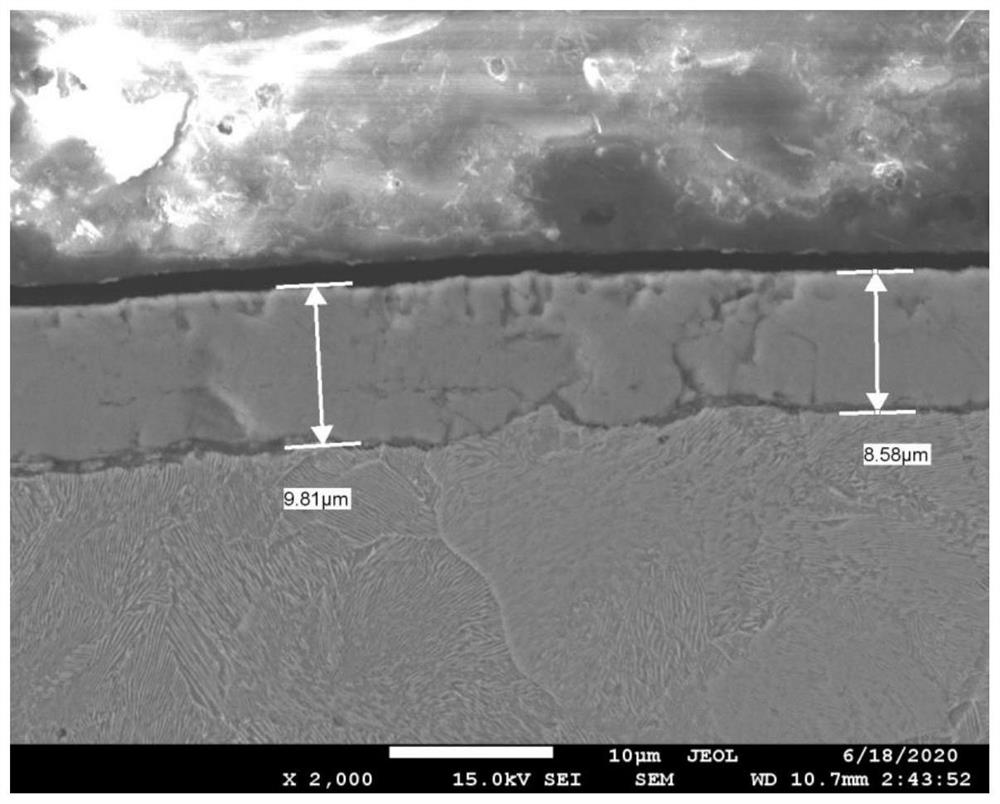

Embodiment 1

[0032] Production of cord steel with a specification of φ5.5mm, composition design C: 0.69%-0.76%; Mn: 0.46%-0.6%; Si: 0.15%-0.3%, Cr≤0.06%; After the billet is rolled at a high line speed, The silk is spun at a spinning temperature of 900°C, and coiled into coils on the air-cooled roller table. The coil is conveyed forward by the air-cooled roller table for controlled cooling. The fan is turned off in the early stage, and the coil passes through the roller table until the temperature reaches 800°C. Then turn on the fan to cool the coil quickly, and cool the coil quickly at a cooling rate of 33.25°C / s. After passing through the Ar3~Ar1 interval, control the cooling rate to slowly cool the phase transition zone. Before the temperature reaches the phase transition point, according to the production environment part Turn on the air cooling of the cooling roller line to let the coil cool down to the phase transition point at a cooling rate of 5°C / s. After reaching the phase transit...

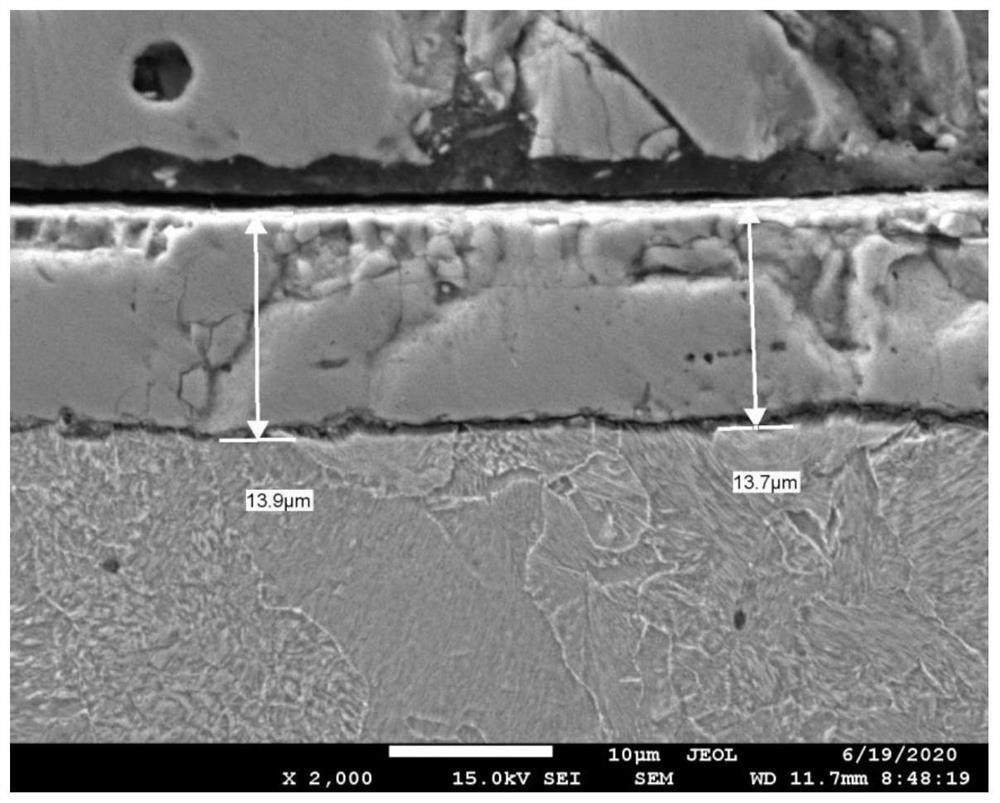

Embodiment 2

[0035]Production of cord steel with a specification of φ5.5, composition design C: 0.79%-0.86%; Mn: 0.46%-0.6%; Si: 0.15%-0.3%, Cr≤0.06%; After the billet is rolled at a high line speed, Spinning at a spinning temperature of 910°C, the wire rod is rolled into a coil on the roller table, and is continuously conveyed by the roller table into the air-cooled roller table for wire-controlled cooling. When entering the cooling control zone, the coil temperature is 880°C, and the coil is naturally cooled to 800°C to equalize the temperature of the coil after passing through the roller table. The coil enters the fast cooling stage. Turn on the air cooling and use the cooling rate of 28.5°C / s to quickly cool the coil. After cooling through the Ar3~Ar1 interval, control the cooling rate to perform slow cooling in the phase transition zone. When the wire temperature is close to the phase transition temperature, The wire is greatly affected by cooling. At this time, turn off the fan (or c...

Embodiment 3

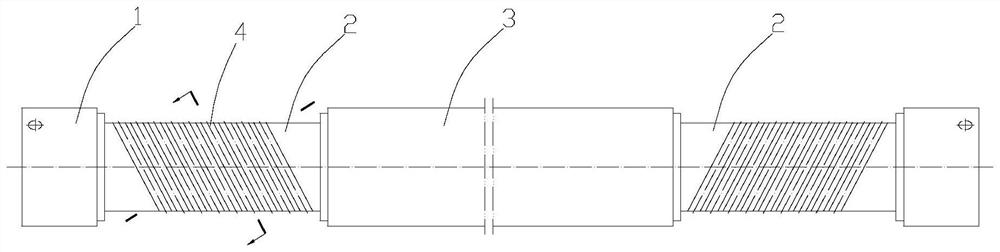

[0038] This embodiment involves the transformation of the idler rollers in the air-cooled roller table line. The reason for the transformation is that the cooling line idler rollers cool slowly on both sides and fast in the middle, that is, the cooling rate of the coils at the overlapping points on both sides is relatively slow. In order to solve this problem, this application has made related improvements to the structure of the idler roll: the idler roll is designed as a roll head 1 at both ends, a roll body 3 in the middle, and a roll neck 2 between the roll body 3 and the two roll heads 1 , the ring diameter of the roll body 3 is greater than the ring diameter of the roll neck 2, and the left and right overlapping points of the wire rod coil on the idler roller correspond to the upper and lower sides of the two roll necks 2 respectively, and the coils between the left and right overlapping points correspond to the roll body 3, so The air cooling of the cooling control rolle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com