Soil washing equipment and method for remediation of heavy metal polluted soil

A technology of contaminated soil and soil leaching, which is applied in the direction of restoration of contaminated soil, separation methods, chemical instruments and methods, etc., can solve the problems of complex ex-situ treatment procedures, large floor space, and high treatment costs, and avoid transportation Difficulty, reduction in processing costs, and reduction in processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

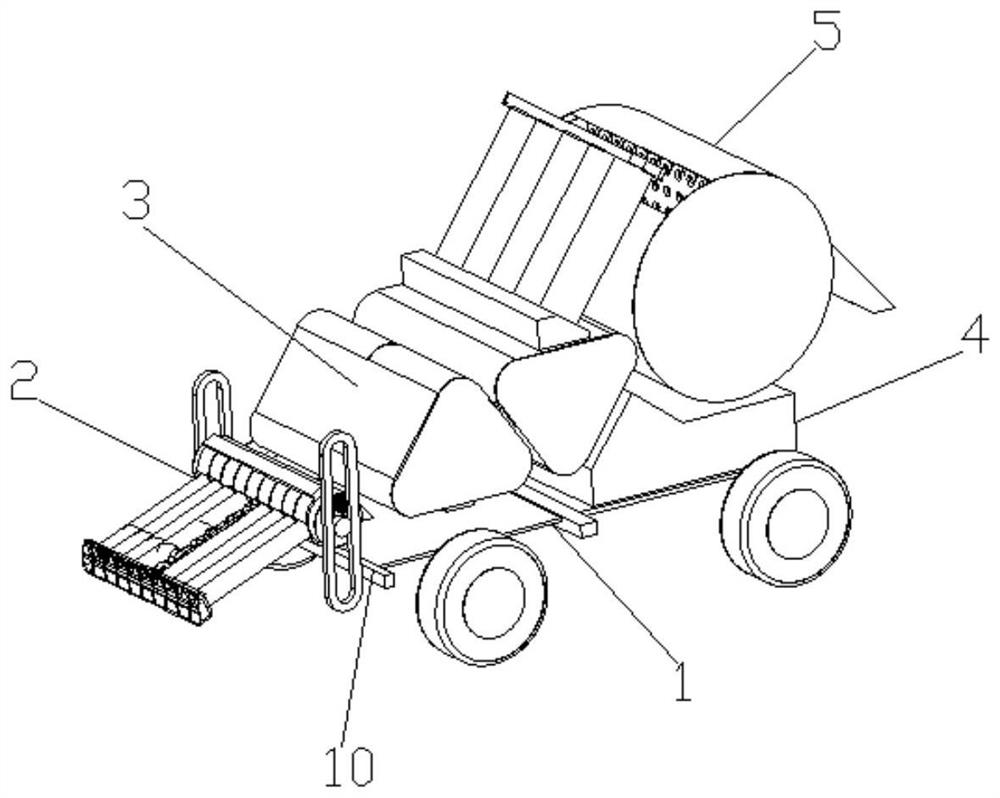

[0043] Such as figure 1The shown soil washing equipment for remediation of heavy metal-contaminated soil includes a movable chassis 1, a soil-taking unit 2 arranged at the front end of the movable chassis 1, arranged in the middle of the movable chassis 1 and communicated with the soil-taking unit 2 The rinsing unit 3 is arranged on the rear end of the movable chassis 1 and the drainage unit 5 is communicated with the rinsing unit 3, and the eluent supply unit 4 is arranged on the movable chassis 1 and communicated with the rinsing unit 3;

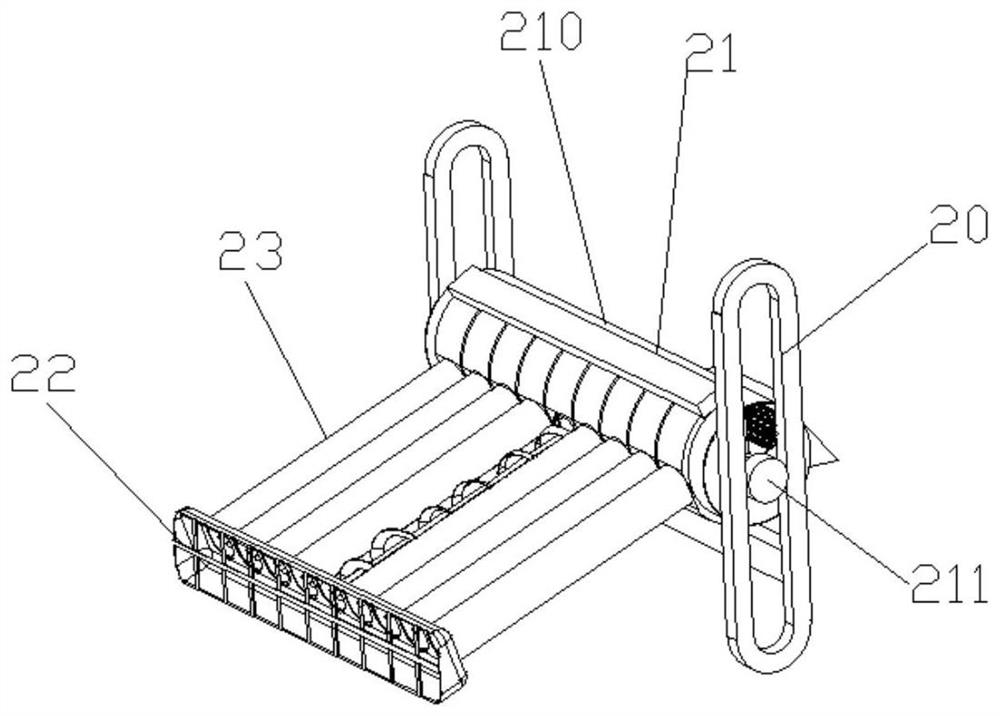

[0044] Such as figure 2 As shown, the soil fetching unit 2 includes an elevating guide rail 20 vertically arranged at the front end of the movable chassis 1, a soil crushing assembly 21 movably arranged on the elevating guide rail 20, an earth entry part 22 that can be in contact with the soil, and is connected with the soil entry part 22, The screw feeding roller group 23 of the soil crushing assembly 21;

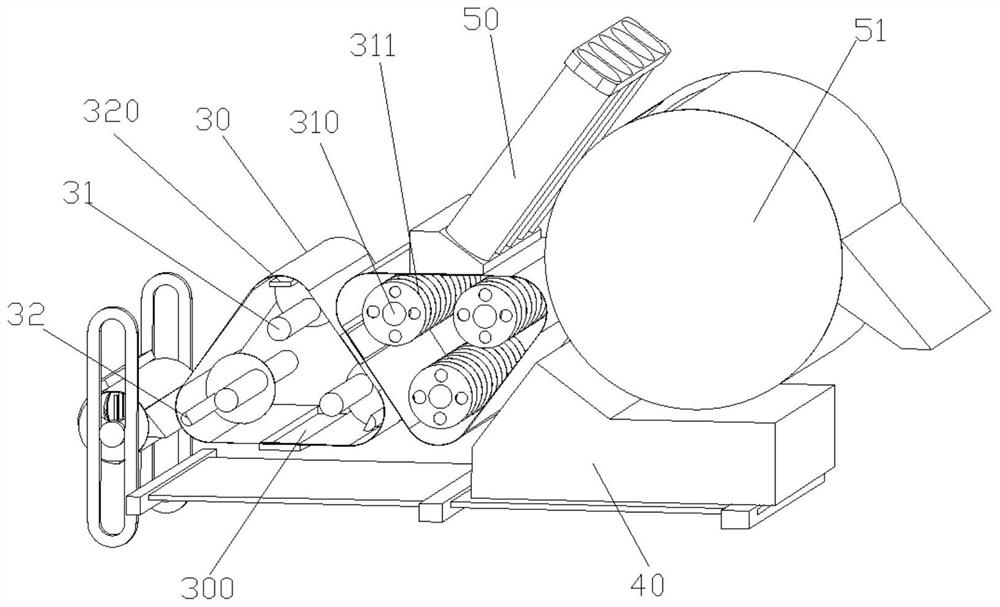

[0045] Such as image 3 As ...

Embodiment 2

[0067] A soil rinsing device for remediation of heavy metal-contaminated soil, comprising a movable chassis 1, a soil-taking unit 2 arranged at the front end of the movable chassis 1, and a leaching unit arranged in the middle of the movable chassis 1 and connected to the soil-taking unit 2 Unit 3, a filter and soil drainage unit 5 arranged on the rear end of the movable chassis 1 and connected to the washing unit 3, and a eluent supply unit 4 arranged on the movable chassis 1 and connected to the washing unit 3;

[0068] The soil fetching unit 2 includes a lift guide rail 20 vertically arranged on the front end of the movable chassis 1, a soil crushing assembly 21 movably arranged on the lift guide rail 20, a soil entry piece 22 that can be in contact with the soil, and is connected to the soil entry piece 22 and the soil crushing assembly. 21 screw feeding roller group 23;

[0069] The rinsing unit 3 includes two horizontally arranged triangular prism-shaped and connected ri...

Embodiment 3

[0097] A soil rinsing device for remediation of heavy metal-contaminated soil, comprising a movable chassis 1, a soil-taking unit 2 arranged at the front end of the movable chassis 1, and a leaching unit arranged in the middle of the movable chassis 1 and connected to the soil-taking unit 2 Unit 3, a filter and soil drainage unit 5 arranged on the rear end of the movable chassis 1 and connected to the washing unit 3, and a eluent supply unit 4 arranged on the movable chassis 1 and connected to the washing unit 3;

[0098] The soil fetching unit 2 includes a lift guide rail 20 vertically arranged on the front end of the movable chassis 1, a soil crushing assembly 21 movably arranged on the lift guide rail 20, a soil entry piece 22 that can be in contact with the soil, and is connected to the soil entry piece 22 and the soil crushing assembly. 21 screw feeding roller group 23;

[0099] The rinsing unit 3 includes two horizontally arranged triangular prism-shaped and connected rins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com