Molten iron temperature measurement process auxiliary method and system based on deep learning

A technology of deep learning and molten iron, applied in the direction of neural learning methods, instruments, biological neural network models, etc., can solve the problems of inaccurate and comprehensive temperature measurement process judgment methods, reduce the unqualified rate of pouring products, improve accuracy, The effect of avoiding operator casualties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

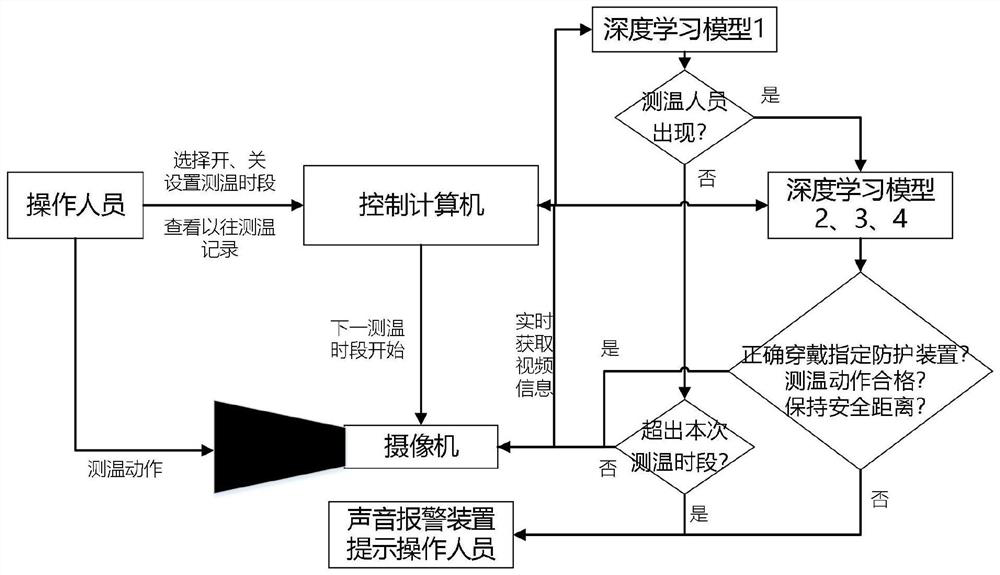

[0034] An embodiment of the present invention provides an auxiliary method for measuring the temperature of molten iron based on deep learning, including:

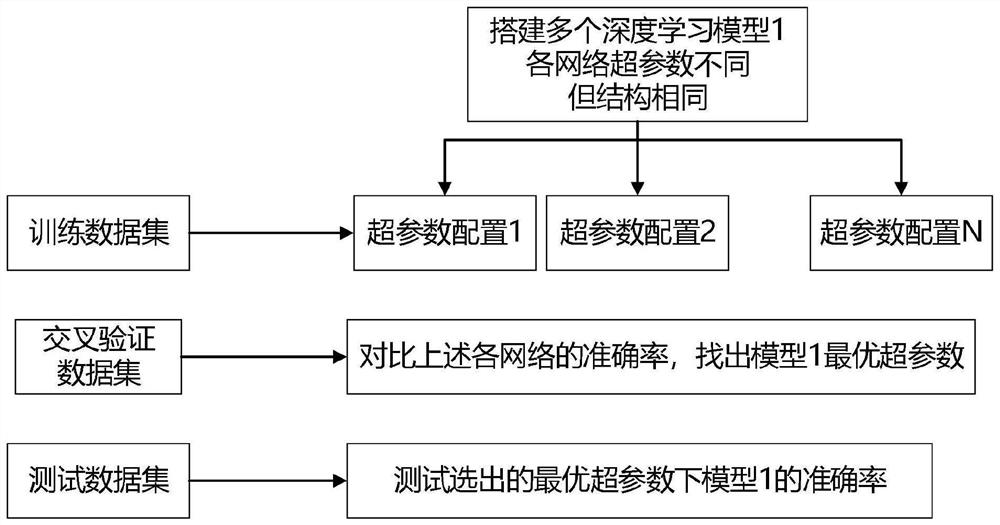

[0035] Four deep learning models are pre-built, among which, the first deep learning model is used to judge whether the temperature measuring personnel appear in the video image, the second deep learning model is used to judge whether the temperature measuring personnel wear the protective device of the specified color correctly, and the third The deep learning model is used to judge whether the temperature measuring posture of the temperature measuring personnel is qualified, and the fourth deep learning model is used to predict the distance between the body parts of the temperature measuring personnel and the molten iron furnace;

[0036] Obtain a large number of temperature measurement action videos of molten iron temperature measurement personnel in the cast iron pouring process. The images in the temperature measuremen...

Embodiment 2

[0062] Based on the same inventive concept, this embodiment provides a process auxiliary system for measuring molten iron temperature based on deep learning, which includes:

[0063] The model building module pre-constructs four deep learning models, wherein the first deep learning model is used to judge whether the temperature measuring personnel appears in the video image, and the second deep learning model is used to judge whether the temperature measuring personnel are wearing the protective protection of the specified color correctly. device, the third deep learning model is used to judge whether the temperature measurement posture of the temperature measuring personnel is qualified, and the fourth deep learning model is used to predict the distance between the body parts of the temperature measuring personnel and the molten iron furnace;

[0064] The model training module obtains a large number of temperature measurement action videos of molten iron temperature measuremen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com