Engine combustion chamber structure, engine and fire pump

A combustion chamber and engine technology, which is applied to combustion engines, engine components, machines/engines, etc., can solve the problems of reduced engine life, poor heat dissipation, damage, etc., to prevent excessive temperature, good cooling effect, and guarantee The effect of the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

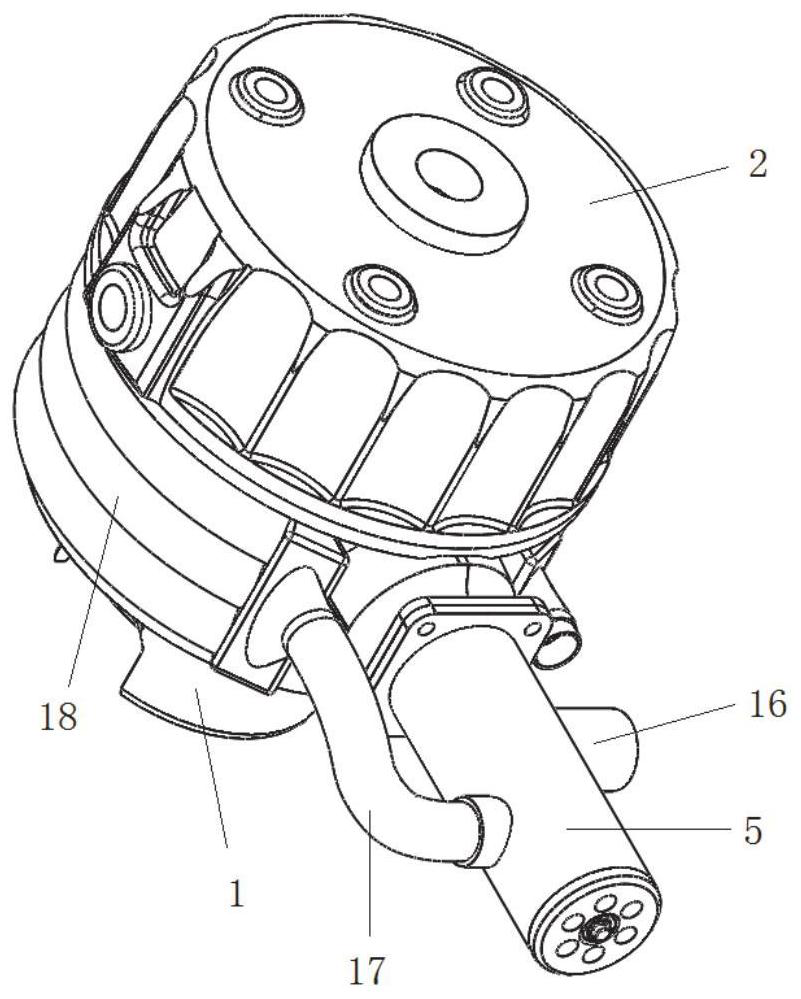

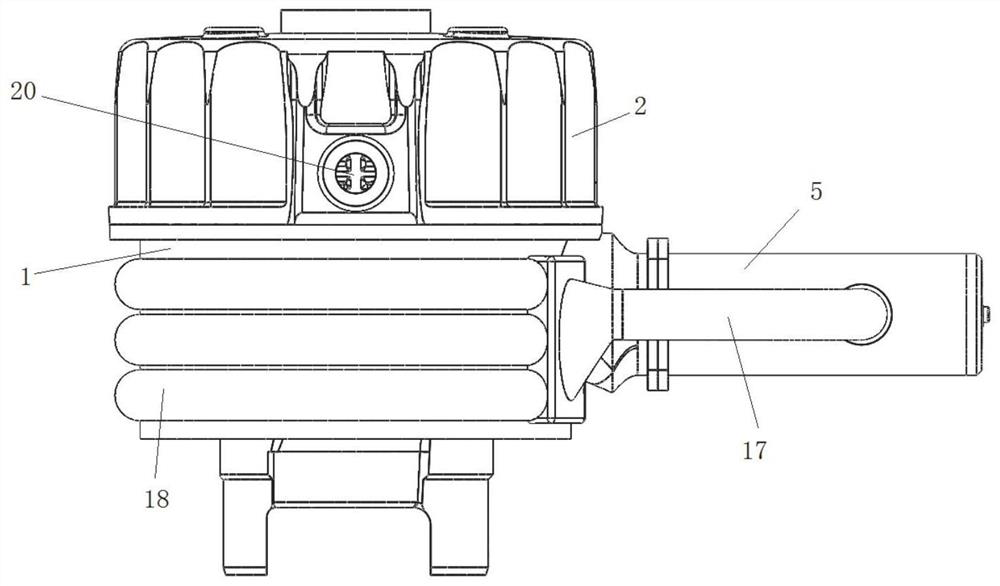

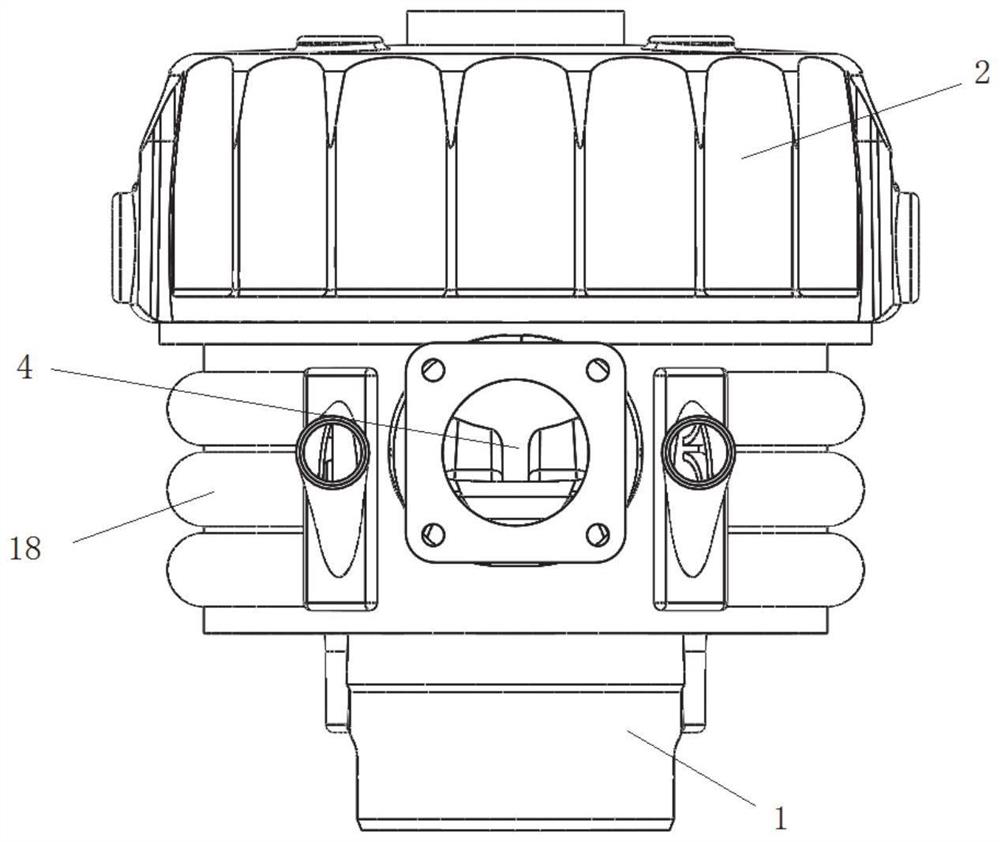

[0034] This embodiment provides a kind of engine combustion chamber structure, is used for the engine of fire pump, as Figure 1-Figure 4 As shown, the combustion chamber structure includes a combustion chamber cylinder block 1, and there is a space for fuel combustion inside the combustion chamber cylinder block. One end of the combustion chamber cylinder block is buckled and fixed with a cavity cover 2, and the cavity cover is used to align the combustion chamber cylinder body. One end of the body is open and closed. A fuel injection plug is installed on the chamber cover for injecting fuel into the combustion chamber.

[0035] The combustion chamber cylinder includes a first cylinder part 1-1 and a second cylinder part 1-2 integrally connected, and an air inlet 3 and an exhaust port 4 are opened on the second cylinder part.

[0036] The above structure is the same as that of the existing fire pump engine combustion chamber, and this embodiment is an improvement on the exis...

Embodiment 2

[0063] This embodiment provides an engine, which is provided with the engine combustion chamber structure described in Embodiment 1. Other structures of the engine may adopt the structure of an existing fire pump engine, and will not be described in detail here.

Embodiment 3

[0065] This embodiment provides a fire pump, which is installed with the engine described in Embodiment 2. The other structures of the fire pump can be those of the existing fire pump, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com