Multifunctional colorful anti-counterfeiting film preparation method based on rotation parameter control

A color film, multi-functional technology, applied in the field of film materials and optical anti-counterfeiting, can solve the problems of high cost of thermochromic materials, strict printing conditions, non-permanent discoloration, etc., to improve appearance performance, long service life, and safety. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

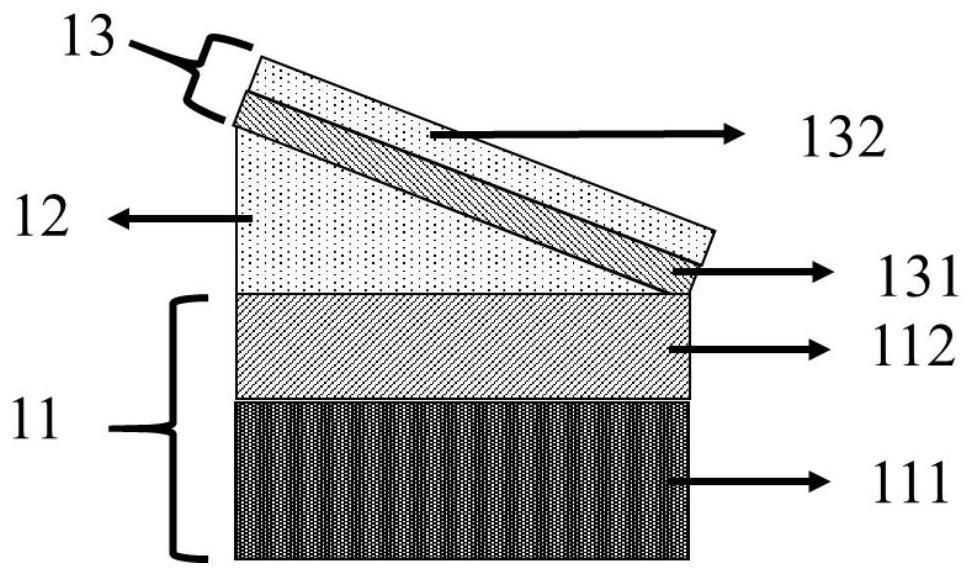

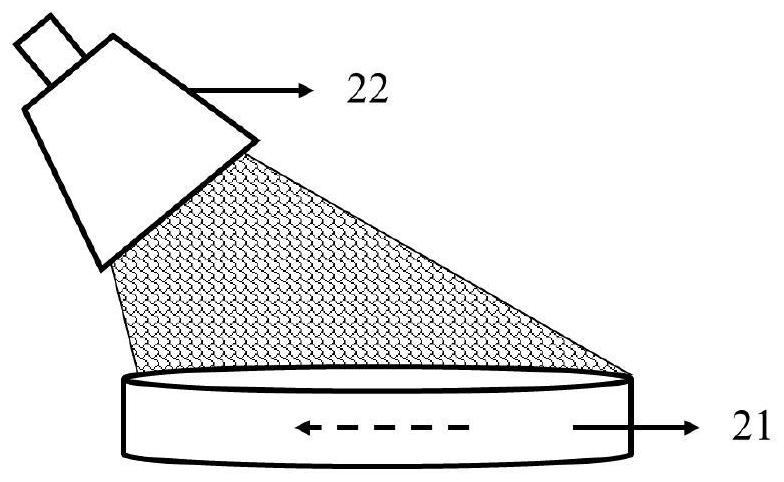

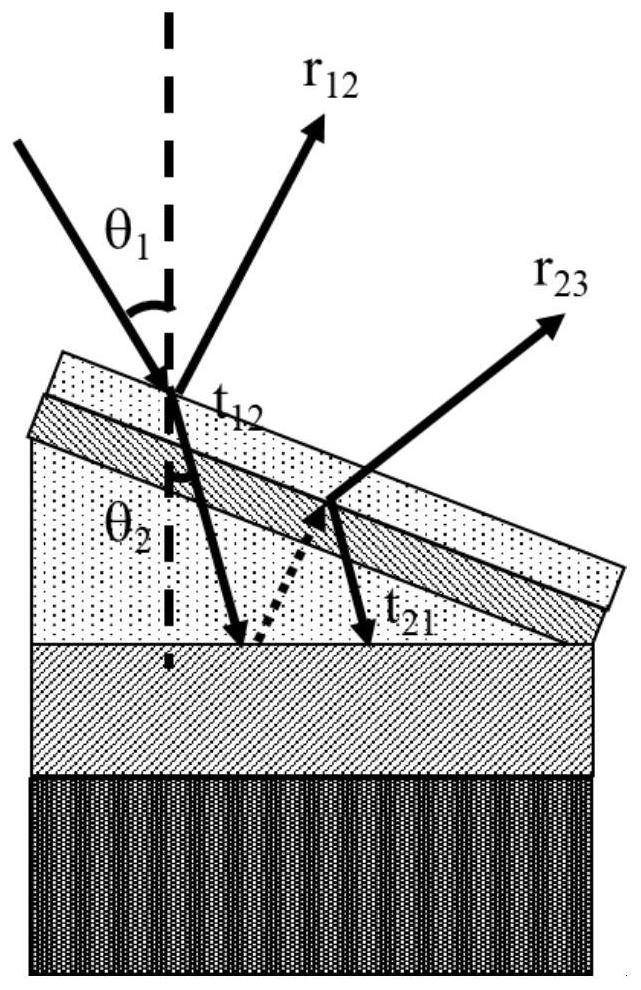

[0043] see figure 1 , this implementation provides a multifunctional color thin film controlled by rotation parameters and its preparation method, which includes: an interference medium layer, a base layer compounded at the bottom of the interference medium layer, and a surface compounded at the top of the interference medium layer Film layer; wherein, the base layer includes a substrate layer, and a carrier layer attached below the substrate layer; the surface film layer includes a functional layer compounded on the top of the above-mentioned interference medium layer, and will be compounded on the functional layer Protective layer on top. The substrate layer, the interference medium layer and the functional layer together form a cavity-type interference resonance structure.

[0044] The carrier layer is a variety of materials in different scenarios, regardless of thickness. The protective layer provides protection against oxidation and the like for the structure, and adop...

Embodiment 1

[0053] like figure 1 As shown, the rotation parameter-controlled interference unit structure provided in this embodiment includes a carrier layer, a substrate layer, a pre-interference medium layer, a functional layer, and a protective layer in sequence from bottom to top.

[0054] The carrier layer is SiO 2 sheet, regardless of thickness; substrate layer and functional layer are made of Ge 2 Sb 2 Te 5 , the thickness is 5nm and 10nm; the pre-interference medium layer adopts ITO, and the thickness of the pre-interference medium layer is 0-150nm. Except for the pre-interference medium layer, the above other layers are all uniform layers.

[0055] When sputtering the pre-interference medium layer, the rotation angle of the rotating platform is 0°, that is, when sputtering, the rotating platform is stationary.

[0056] Will Figure 4 The interferometric unit structure shown in the three periodic stacking, the structure is as Figure 7 shown. It includes a carrier layer, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com