Stirring device for efficiently aging slurry

A stirring device and high-efficiency technology, applied in the field of machinery, can solve the problems of heavy material deposition, uneven material, full contact between unfavorable materials and air, etc., to prevent layered precipitation, improve aging speed, and ensure aging effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

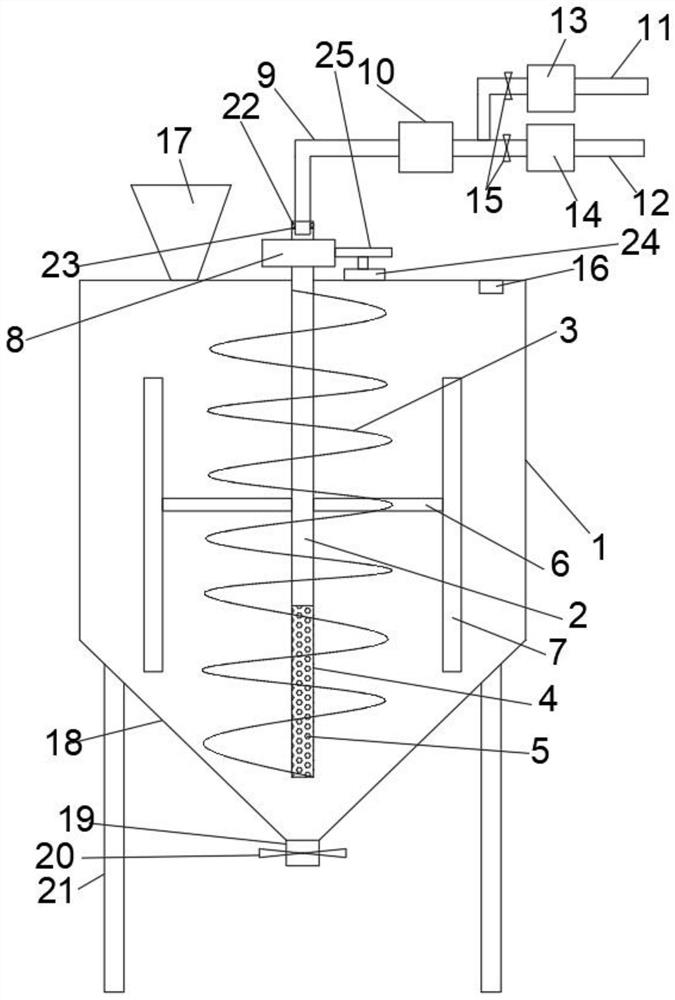

[0018] Such as figure 1 A stirring device for efficient aging of slurry is shown, a stirring tank 1, a hollow stirring shaft 2, a spiral stirring fan blade 3, a porous part 4, a vent hole 5, a transverse connecting rod 6, a vertical stirring blade 7, a second Gear 8, air pipe 9, air pump 10, first branch pipe 11, second branch pipe 12, refrigerator 13, heater 14, solenoid valve 15, temperature sensor 16, feed port 17, tapered part 18, discharge Port 19, valve 20, leg 21, bearing 22, oil seal 23, motor 24 and first gear 25.

[0019] The top of the mixing tank 1 forms a feed inlet 17 , the bottom forms a conical portion 18 , and the bottom of the conical portion 18 forms a discharge port 19 , and a valve 20 is installed on the discharge port 19 . Legs 21 are installed at the bottom of the tapered portion 18 .

[0020] The inner shaft of the stirring tank 1 is connected with a hollow stirring shaft 2, and the middle and lower part of the hollow stirring shaft 2 is fixed with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com