Preparation method of folding filter element capable of removing heavy metals

A folded filter element, heavy metal technology, applied in chemical instruments and methods, filtration treatment, adsorption water/sewage treatment, etc. To achieve the effect of reducing waste liquid discharge, efficient and stable removal effect, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Embodiment 1, first utilize the melt-blown equipment to prepare the non-woven fabric of polytrimethylene terephthalate; The above-mentioned non-woven fabric is put into concentration and is 10%, and temperature is in the chitosan aqueous solution of 90 ℃, after reacting for 24h, take out ; Wash the reacted non-woven fabric with pure water at 40°C for 10 minutes; put the rinsed non-woven fabric in an oven at 60°C for 30 minutes; make the dried non-woven fabric into a folded filter element.

[0020] The pleated filter element in this embodiment is a relatively common structure on the market, basically including a central rod, a shell, and a filter membrane between the central rod and the shell. The filter membrane here is made of modified non-woven fabric. The folds form pleats with pleat valleys at the base central stem, pleat peaks that touch the shell, and the legs of the pleat peaks.

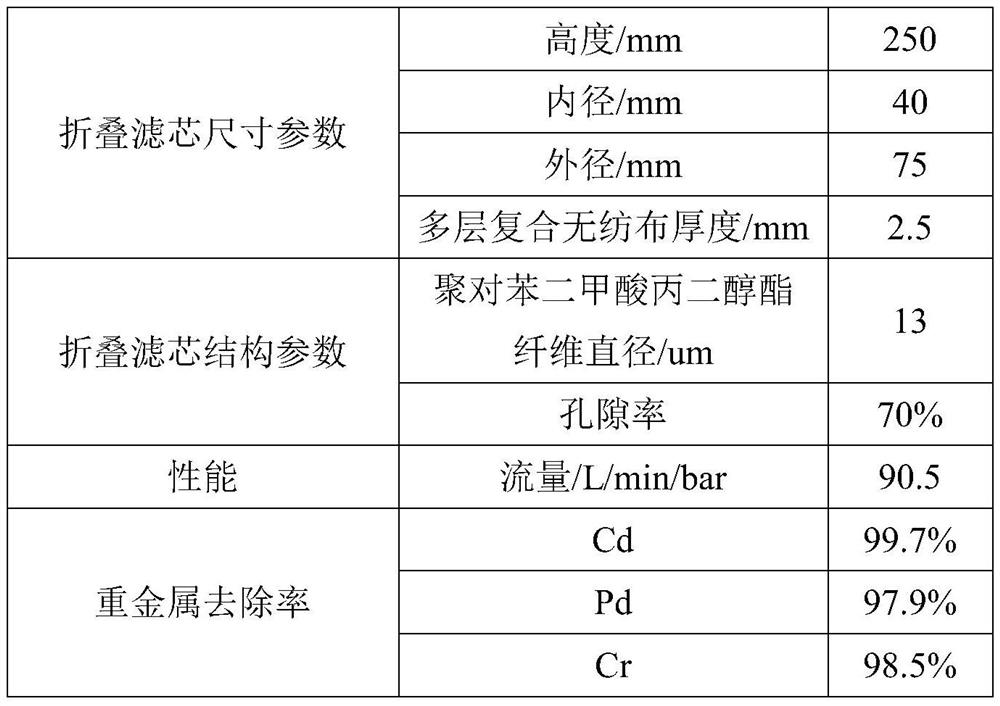

[0021]

Embodiment 2

[0022] Embodiment 2, at first utilize melt-blown equipment to prepare the body non-woven fabric of polybutylene terephthalate; The above-mentioned filter element is put into concentration and is 5%, and temperature is in the aqueous solution of ethylenediaminetetraacetic acid of 70 ℃, reacts After 8 hours, take it out; wash the reacted filter element in 60°C pure water for 20 minutes; put the rinsed filter element in a 60°C oven to dry for 30 minutes; make the dried non-woven fabric into a folded filter element;

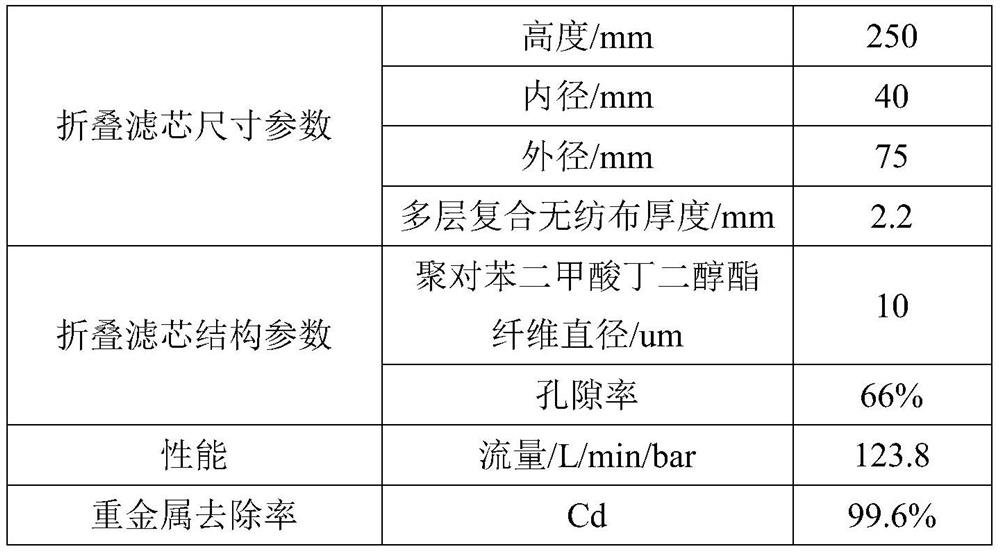

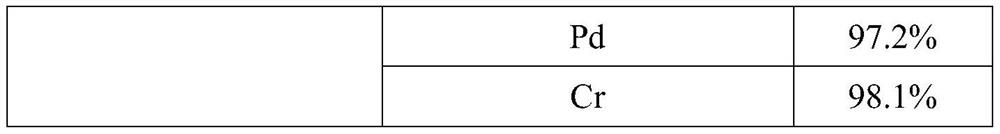

[0023]

[0024]

Embodiment 3

[0025] Embodiment 3, first utilize melt-blowing equipment to prepare the non-woven fabric of polycarbonate; Put the above-mentioned filter element into the aqueous solution of nitrilotriacetic acid with a concentration of 10% and a temperature of 80°C, and take it out after reacting for 12 hours; Wash the filter element in pure water at 60°C for 15 minutes; put the rinsed filter element in a 60°C oven to dry for 30 minutes; make the dried non-woven fabric into a folded filter element;

[0026]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com