Cold charging alloy pipe dismounting method

An alloy tube and cold-loading technology is applied in metal processing, metal processing equipment, manufacturing tools, etc., and can solve the problems of easy damage to the base material of the cold-loaded base 2, low disassembly efficiency, and difficulty in disassembling the cold-loaded alloy tube 1. To achieve the effect of easy realization of the dismantling method, good dismantling effect and low dismantling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

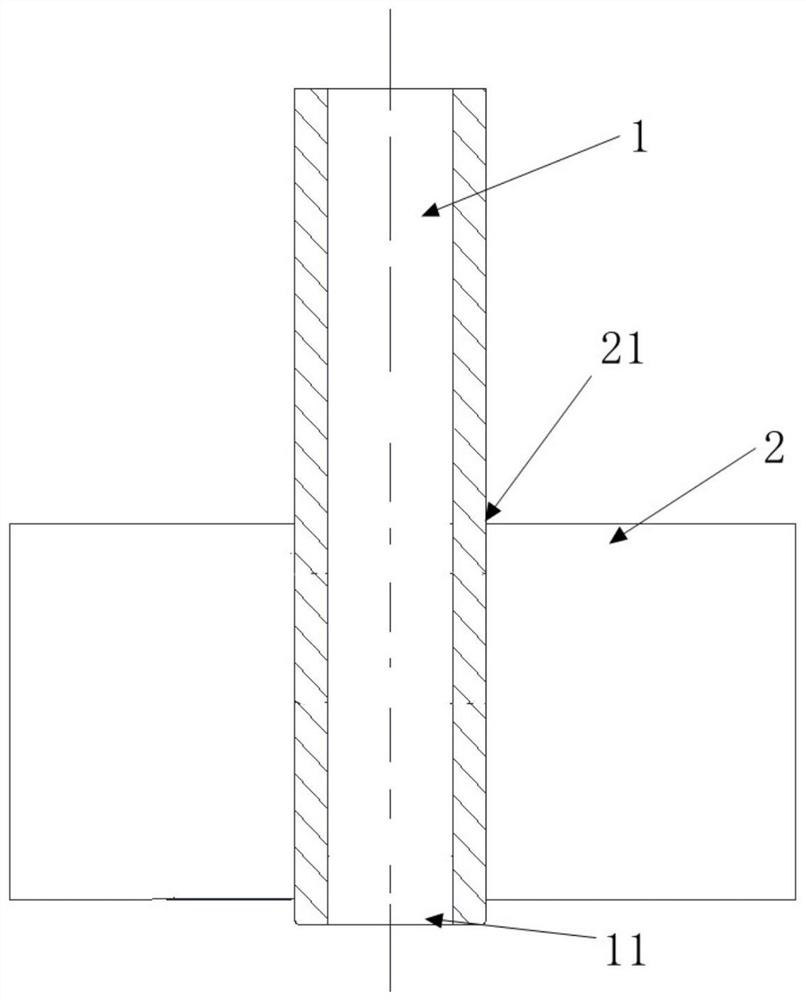

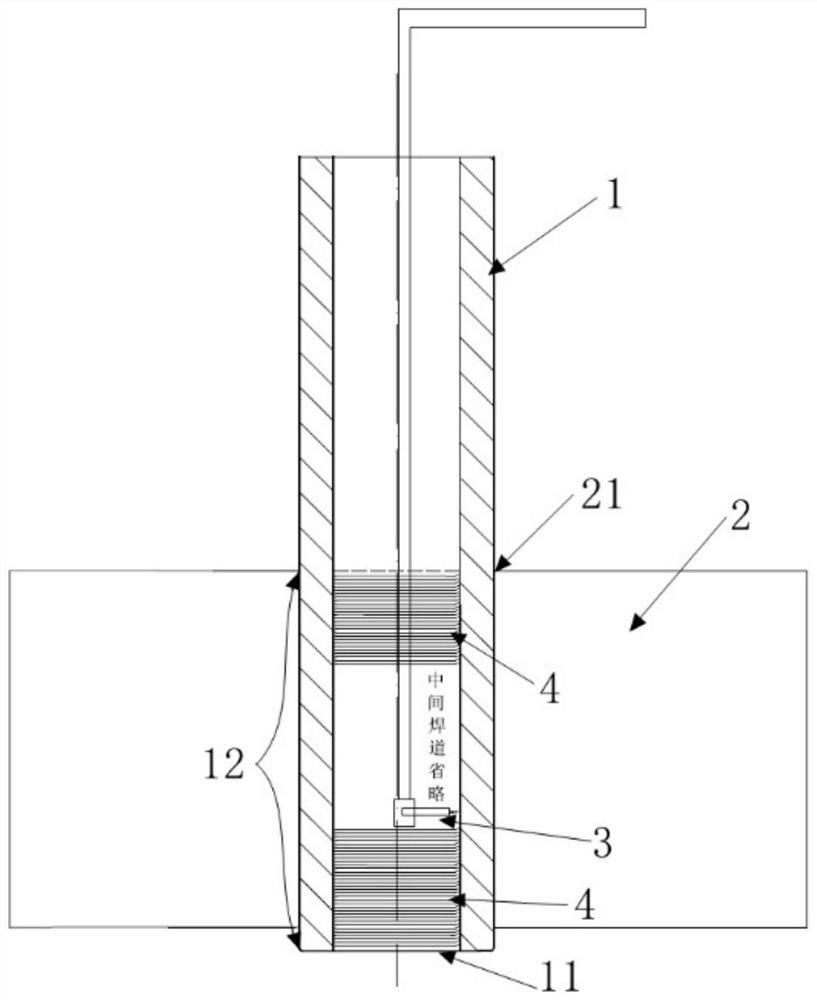

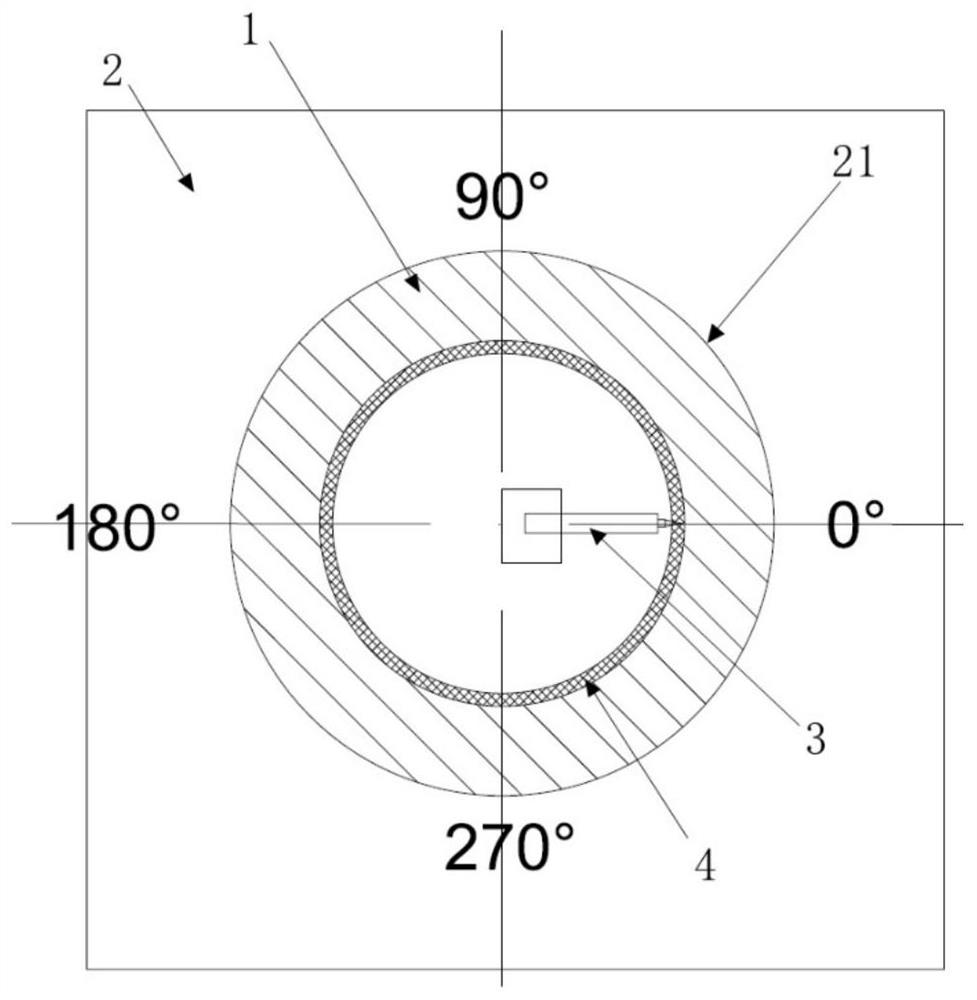

[0044] Circumferentially welded, as attached figure 2 , 3 As shown (attached figure 2 The middle bead is omitted), start arc welding from any position, perform single-layer or multi-layer welding in the counterclockwise or clockwise direction, each bead 4 is full circle or intermittent welding, and is carried out in continuous or intermittent welding state For the next welding (that is, 4 welds are spirally or spaced), the circumferential welding speed is 50mm-70mm / min. After the welding is completed, the inner wall of the welding operation section 12 is distributed in a single layer or evenly distributed in multiple layers along the axial direction. weld bead 4.

Embodiment 2

[0046] Axially welded, as attached Figure 4 , 5 As shown (attached Figure 4 The middle bead in the middle bead is omitted), start arc welding from any position, perform single-layer or multi-layer welding along the axial direction, and perform the next welding in the continuous / stop welding state (that is, weld bead 4 helical or spaced distribution), the axis The welding speed in the direction is 70mm-80mm / min. After the welding is completed, the inner wall of the welding operation section 12 is distributed in a single layer or in multiple layers in the circumferential direction with weld beads 4 parallel to the axis.

[0047] 4. During the welding process, monitor the temperature of the tube wall of the alloy tube 1 and the cold loading base 2. If the temperature of the inner wall of the cold loading hole 21 is too high or the temperature difference is too large, it may cause thermal deformation of the base metal of the cold loading base 2 and cause When damaged, stop wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com