Assembly type wall tile mounting structure and method

A technology for installing structure and wall tiles, applied to floors, building structures, covering/lining, etc., can solve problems such as poor assembly aesthetics and applicability, and sealing strip detachment, so as to improve safety and Aesthetics, cable disassembly and assembly guarantee, satisfying the effect of quick adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

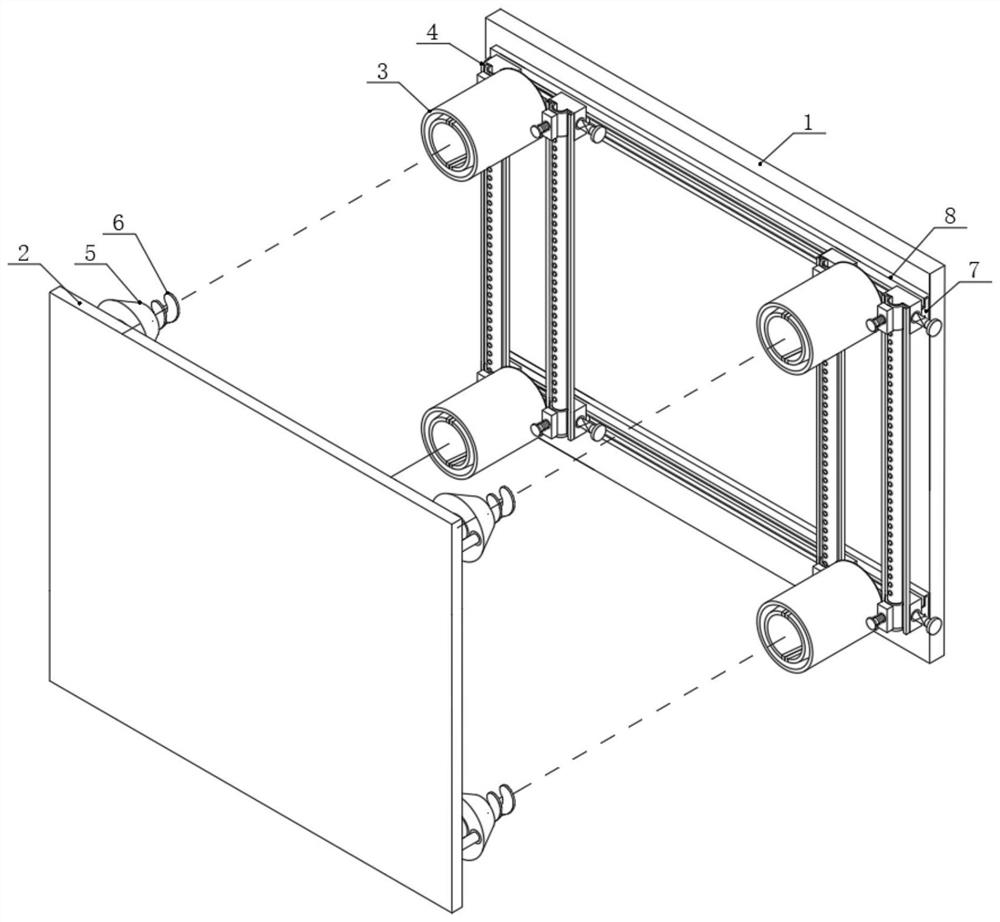

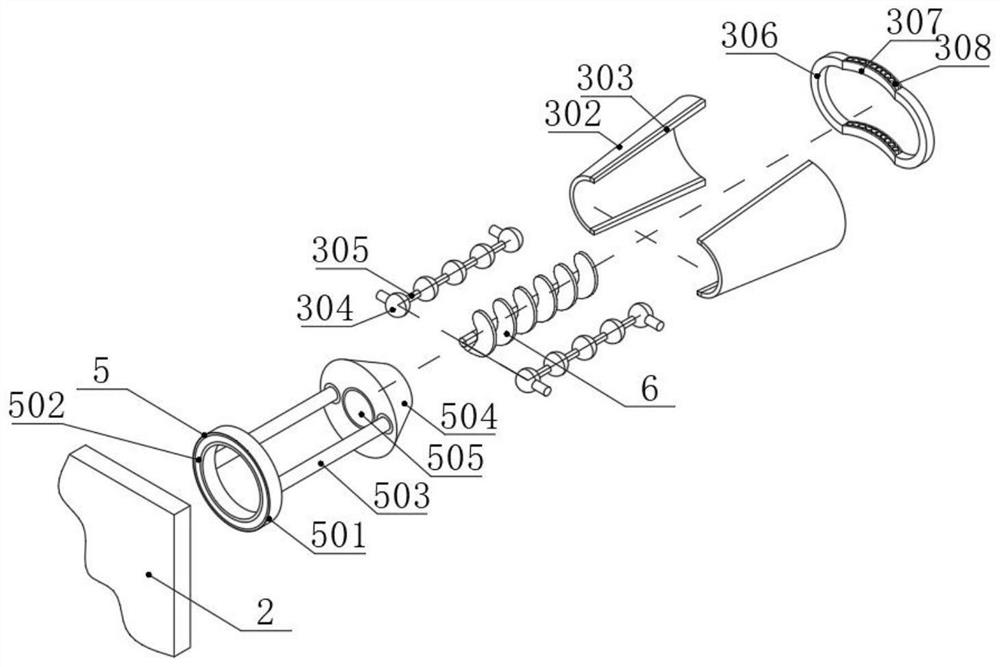

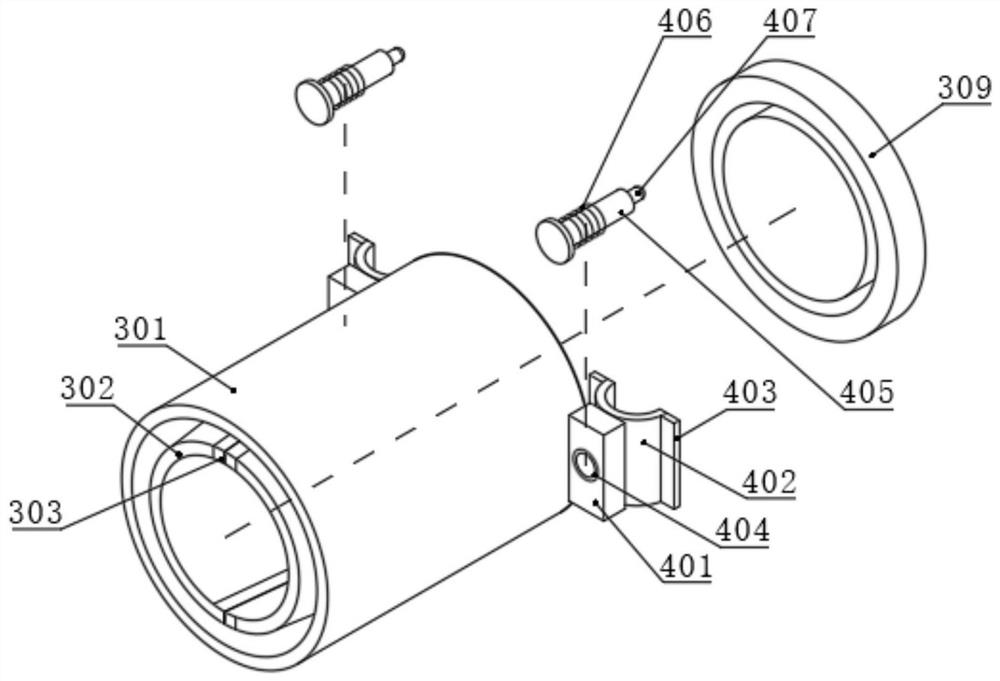

[0035] see Figure 1-7 , the present invention provides a technical solution: a prefabricated wall tile installation structure, including an assembly base 1 and a decorative brick 2, the decorative brick 2 is movably assembled on one side of the assembly base 1, and the two sides of the assembly base 1 are Both ends are fixed with a slide rail seat 8, and the inner cavity of the slide rail seat 8 is slidably connected with an assembly block 7. One side of the assembly block 7 is fixed with an adjustment mechanism 4, and one side of the adjustment mechanism 4 is movably connected with an assembly block. Mechanism 3, a plurality of assembly nails 6 are fixed on one side of the decorative brick 2, and the assembly nails 6 are detachably connected in the assembly mechanism 3, and the outer wall of the assembly nail 6 is provided with an abutment mechanism 5, The two sides of the abutment mechanism 5 are attached to the assembly mechanism 3 and the decorative brick 2 respectively; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com