Device and method for automatically arraying and uniformly adding grinding media of ball mill

A technology of grinding medium and adding device, which is applied in the direction of grain processing, etc., can solve the problems of easy ball jamming, ball blocking, high failure rate of equipment in the ball bin, and achieve the effect of solving the stuck state and continuous adding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

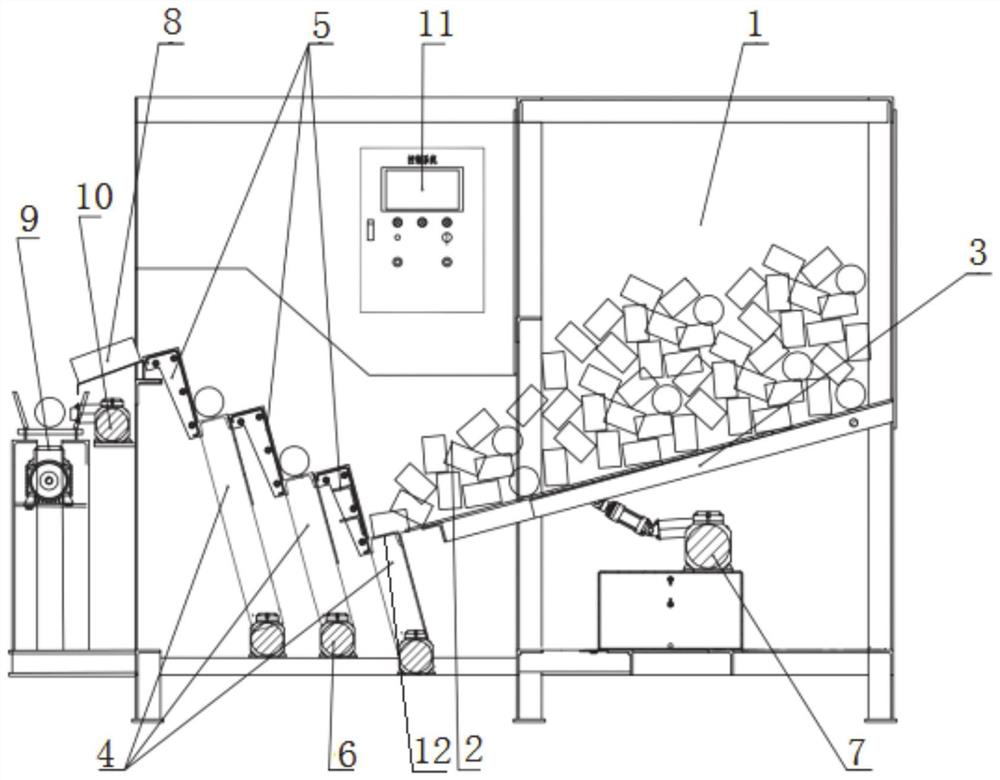

[0028] This embodiment provides a device for automatically aligning and evenly adding the grinding media of the ball mill, such as figure 1 As shown, it includes a storage bin 1, a whole row bin 2, a conveying device 9 and an adding device 10. The storage bin 1 is provided with a catch-up device, and the whole row bin 2 is provided with a multi-stage interval setting whole row lifting device 4; The material bin 1 and the alignment bin 2 are connected through the material inlet, and the conveying device 9 and the adding device 10 are arranged outside the alignment bin 2 .

[0029] Wherein, the material inlet is an opening with a certain height and width, which is opened along the side walls of the storage bin 1 and the alignment bin 2 .

[0030] Specifically, the feeding device includes a feeding board 3 and an adjustment mechanism 7, one end of the feeding board 3 is rotatably connected (for example, hinged) to the inner wall of the storage bin 1, and the other end of the feed...

Embodiment 2

[0043] This embodiment provides a method for automatically arranging and evenly adding the grinding medium of a ball mill. Using the device described in Embodiment 1, the grinding medium in the storage bin enters the arranging bin through the feeding device, and the first-level arranging and lifting The lifting plate of the device is lifted until its working surface is coplanar with the material guide surface of the first-level material guide step, and the grinding medium enters the second-level whole-row lifting device; The medium is arranged in a straight line, and is lifted step by step to the discharge end of the whole column warehouse 2 by means of the material guide step 5.

[0044] After that, the grinding medium falls to the conveying device according to the arrangement through the chute, and the conveying device transports the grinding medium to the adding device at the end. Mining media, the conveying device will automatically run to replenish the next grinding media...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com