Positive pole piece and solid-state battery comprising same

A positive pole piece and solid-state electrolyte technology, applied in the field of solid-state batteries, can solve problems such as high interface impedance, poor contact tightness, and small contact area, and achieve excellent cycle performance, improve interface impedance, and good interface contact performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0072] The present invention does not limit the preparation method of the positive pole piece. In the first optional embodiment, the positive pole piece of the present invention can be prepared by the following method:

[0073]The positive electrode slurry is obtained by mixing the positive electrode active material, polymer monomer, conductive agent, lithium salt, initiator and solvent to initiate polymerization; the positive electrode slurry is coated on one or two functional surfaces of the positive electrode current collector, and after After drying treatment, the positive electrode sheet is prepared.

[0074] In the second optional embodiment, the positive electrode sheet of the present invention can be prepared by the following method:

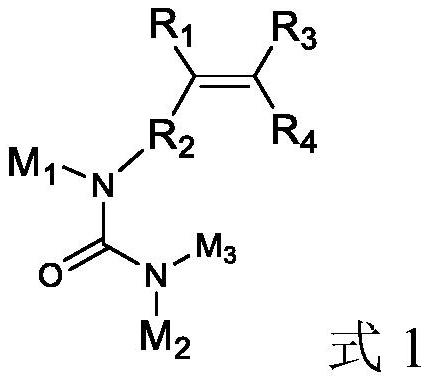

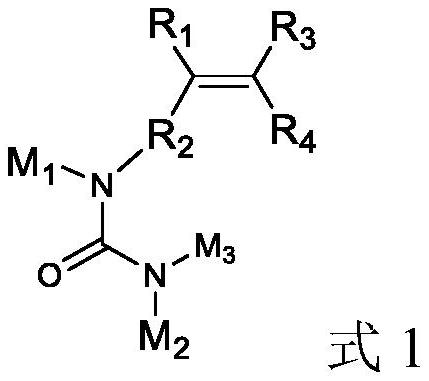

[0075] Mixing polymer monomers and initiators and initiating a polymerization reaction to prepare a polymer; mixing the prepared polymer, positive electrode active material, conductive agent, lithium salt and a second solvent to obtain a...

Embodiment 1

[0088] The preparation method of the solid-state battery of this embodiment includes the following steps:

[0089] 1) Preparation of positive electrode sheet

[0090] The preparation method of positive pole piece comprises the following steps:

[0091] S1: Add the raw materials for the first monomer preparation into dimethyl sulfoxide to fully react to obtain the first monomer, then add the first monomer and the second monomer to the polymerization solvent and mix them uniformly, then add the initiator and mix them to initiate Polymerization reaction to obtain polymer.

[0092] S2: Mix and disperse the positive electrode active material, polymer, lithium salt, auxiliary agent, conductive agent, binder, etc. in the solvent to obtain the positive electrode slurry; apply the positive electrode slurry on the two functional surfaces of the aluminum foil, and bake at 100°C After drying for 24 hours, rolling and cutting, the positive electrode sheet was obtained.

[0093] 2) Prepa...

Embodiment 2

[0104] The preparation method of the solid-state battery of this embodiment includes the following steps:

[0105] 1) Preparation of positive electrode sheet

[0106] The preparation method of positive pole piece comprises the following steps:

[0107] Mix and disperse the positive electrode active material, polymer monomer, initiator, lithium salt, auxiliary agent, conductive agent, and binder in the solvent to obtain the positive electrode slurry; apply the positive electrode slurry on the two functional surfaces of the aluminum foil, 55 After polymerization for 3 hours at °C, the positive electrode slurry was dried at 100 °C for 24 hours to obtain a positive electrode sheet.

[0108] 2) Preparation of negative electrode sheet

[0109] The 50 micron copper-based composite lithium provided by Tianjin Zhongneng Lithium Industry Co., Ltd. is used as the negative electrode, in which the thickness of the copper foil is 10 microns, and the lithium layer is 20 microns;

[0110] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com