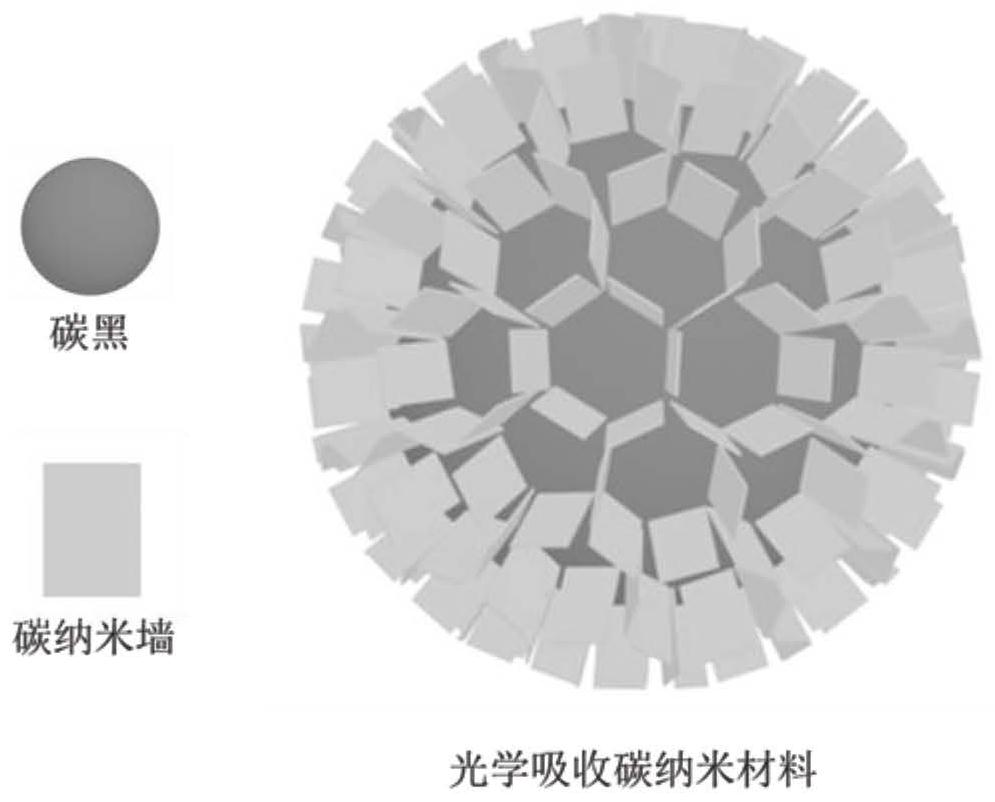

High-optical-absorption carbon nanomaterial and preparation method thereof

A carbon nanomaterial and nanomaterial technology, which are applied in the field of high optical absorption carbon nanomaterials and their preparation, can solve the problems of low impedance matching degree, reduce the light absorption ability of materials, limit the development of light absorption coating, etc., and achieve good interface impedance matching, The effect of efficient optical absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] refer to figure 1 , a high optical absorption carbon nanomaterial, using carbon black with an average particle size of 1000nm as a substrate, and vertically growing carbon nanowalls on its surface through a tubular radio frequency-plasma enhanced chemical vapor deposition system, the preparation method is as follows:

[0022] (1) Evenly spread the dry carbon black particles in the quartz boat, and place the quartz boat in the quartz tube heating zone of the chemical vapor deposition system, and then vacuumize the deposition device.

[0023] (2) Feed the reducing gas hydrogen into the deposition device, the flow rate is 30 sccm, and the temperature is raised to 700° C., and kept at this temperature for 40 minutes to reduce or eliminate defects such as stress, dislocation and impurities on the carbon black surface.

[0024] (3) Regulate the power of the radio frequency device to be 300W, and keep the temperature and hydrogen flow of step (2), feed 30sccm methane and 30scc...

Embodiment 2

[0028] A kind of high optical absorption carbon nano material, adopts the carbon black that average particle size is 2000nm as matrix, grows carbon nano wall vertically on its surface by tubular radio frequency-plasma enhanced chemical vapor deposition system, and its preparation method is as follows:

[0029] (1) Evenly spread the dry carbon black particles in the quartz boat, and place the quartz boat in the quartz tube heating zone of the chemical vapor deposition system, and then vacuumize the deposition device.

[0030] (2) Feed the reducing gas hydrogen into the deposition device, the flow rate is 30 sccm, and the temperature is raised to 700° C., and kept at this temperature for 40 minutes to reduce or eliminate defects such as stress, dislocation and impurities on the carbon black surface.

[0031] (3) Regulate the power of the radio frequency device to be 300W, and keep the temperature and hydrogen flow of step (2), feed 30sccm methane and 30sccm argon to grow the carb...

Embodiment 3

[0035] A kind of high optical absorption carbon nano material, adopts the carbon black that average particle size is 2000nm as matrix, grows carbon nano wall vertically on its surface by tubular radio frequency-plasma enhanced chemical vapor deposition system, and its preparation method is as follows:

[0036] (1) Evenly spread the dry carbon black particles in the quartz boat, and place the quartz boat in the quartz tube heating zone of the chemical vapor deposition system, and then vacuumize the deposition device.

[0037] (2) Feed the reducing gas hydrogen into the deposition device, the flow rate is 30 sccm, and the temperature is raised to 700° C., and kept at this temperature for 40 minutes to reduce or eliminate defects such as stress, dislocation and impurities on the carbon black surface.

[0038] (3) Regulate the power of the radio frequency device to be 300W, and keep the temperature and hydrogen flow of step (2), feed 30sccm methane and 30sccm argon to grow the carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com