Preparation method of dry-method electrode pole piece, electrode pole piece and battery cell

An electrode pole piece and dry method technology, which is applied in the field of battery preparation, can solve the problems of self-supporting membrane hole edges, uneven feeding, and excessive material volume, and achieve the goal of improving the poor uniformity of the membrane and improving the quality and performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention relates to a preparation method of a dry-process electrode pole piece, which comprises the steps of preparing a fibrous mixed material from raw material powder, stirring and sieving the mixed material to obtain a pole piece powder, and the pole piece powder The step of preparing electrode pole pieces after processing.

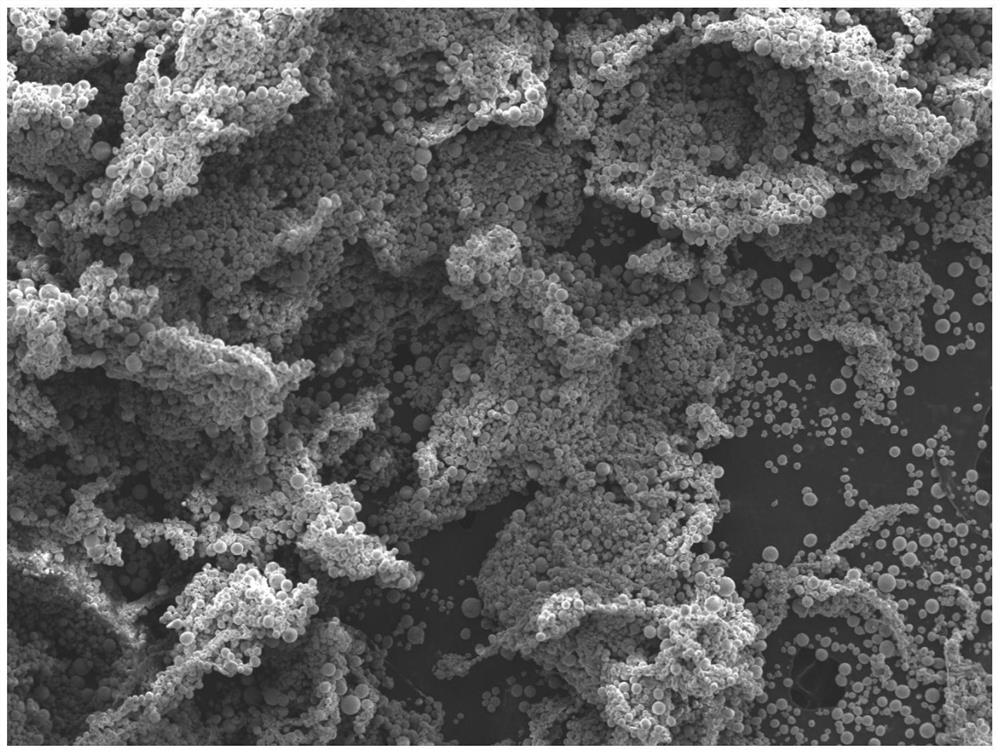

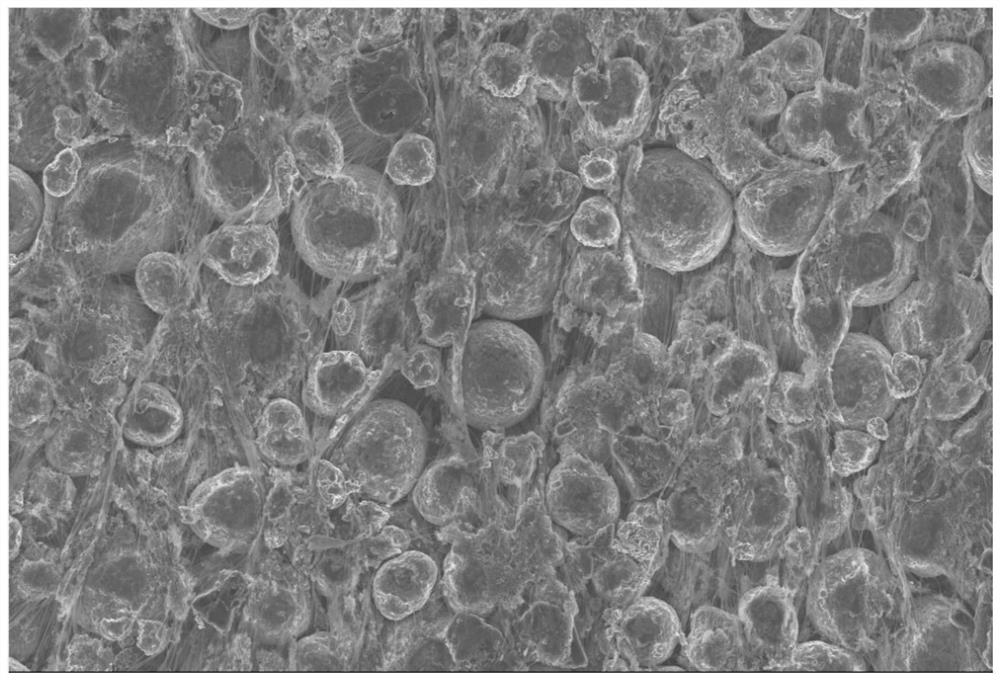

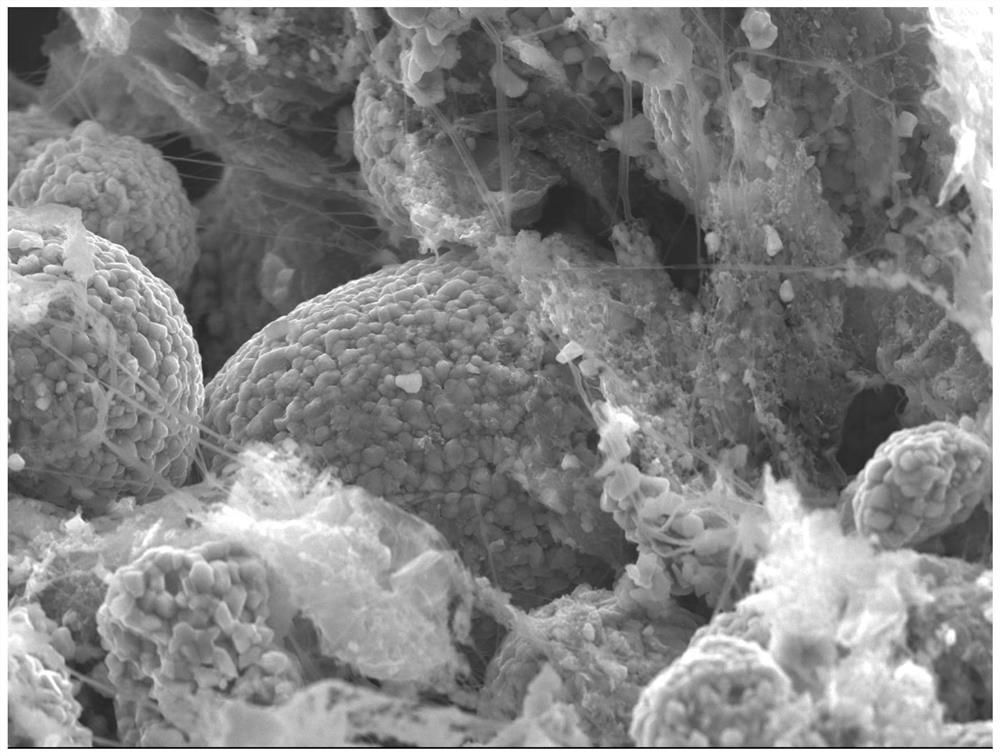

[0032] In the preparation method of the dry electrode pole piece of the present invention, after going through powerful fibrosis steps such as ultra-high-speed stirring or grinding, the obtained material has a high degree of fibrosis, and can be formed into agglomerates by lightly kneading by hand. The raw material is stirred slowly at low speed first, and then stirred quickly at high speed to obtain agglomerated material with small particles. The material passes through the screen, and the screened granular material is directly fed into the roller press to obtain a sheet of self-supporting film directly. The self-supporting film has good s...

Embodiment 1

[0064] According to the positive electrode active material NCM811 (NCM represents its main components nickel, cobalt, manganese, while 811 represents the ratio of the three components 8:1:1) accounted for 92% by weight, and the conductive agent SP accounted for 2% by weight , Conductive agent activated carbon accounts for 2% by weight, binder PTFE accounts for 4% by weight, negative electrode active material Gr accounts for 97% by weight, conductive agent SP accounts for 1% by weight, and binder PTFE accounts for 2% by weight The ratio is mixed and fiberized.

[0065] The obtained highly fibrous material is subjected to the "binder fiberization control process", that is, the material is put into a crescent knife mixer for slow stirring for 3 minutes, and fast stirring for 1 minute, and then the material is sieved through an 18-mesh sieve. , to obtain the regulated material after sieving.

[0066] Put the regulated material into the roller press and feed it to obtain a self-su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com