Efficient paint dipping device for transformer winding

A transformer winding and varnish dipping technology, which is applied in the field of transformers, can solve the problems of prolonging the varnish dipping process, long soaking time, and lack of drying devices, etc., and achieve the effects of shortening the varnish dipping process, improving automation, and speeding up the process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

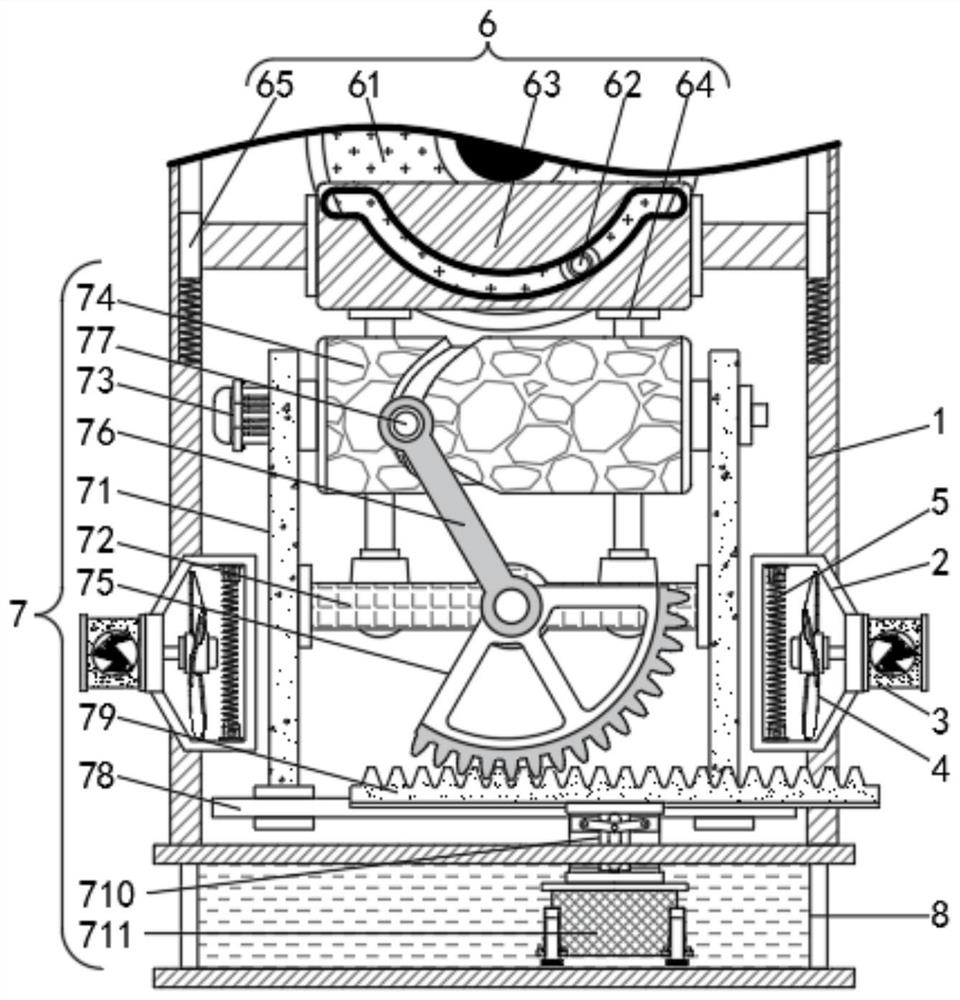

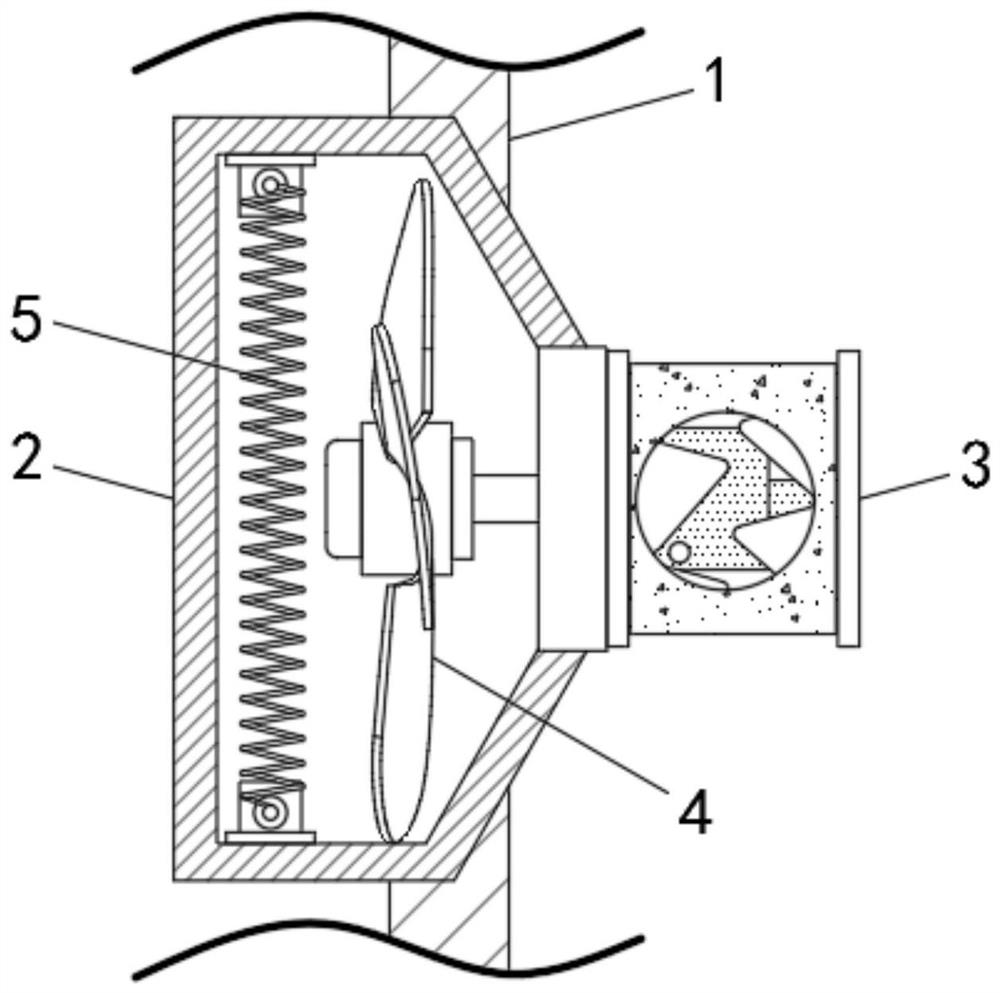

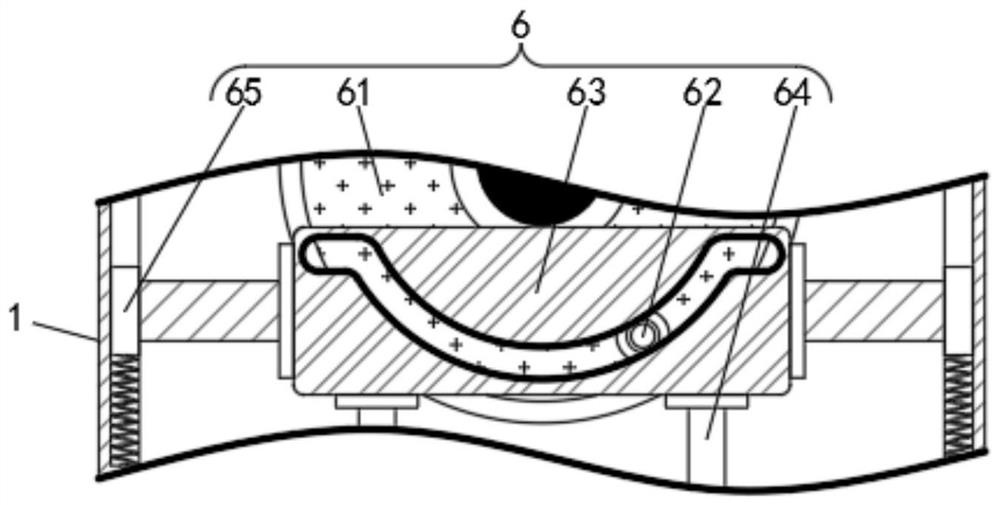

[0024] see Figure 1-3 , a high-efficiency paint dipping device for transformer windings, comprising a device main body 1, an air diffuser cover 2 is arranged on both sides of the device main body 1, a first motor 3 is fixedly connected to the outer end of the device main body 1, and the rotating shaft of the first motor 3 The fan blade 4 is fixedly connected to the top, and the inner side of the fan blade 4 is provided with a heating wire 5. The upper end of the equipment body 1 is provided with a lifting mechanism 6. The lifting mechanism 6 includes a driving disc 61, and the front end of the driving disc 61 is fixedly connected with a cylindrical pin 62. The outside of the cylindrical pin 62 is movably connected with a lifting plate 63, and the rear end of the drive plate 61 is fixedly connected with an output motor. The inside of the lifting plate 63 is provided with an arc-shaped groove, and the radius of the arc-shaped groove is the same as the radius of the circular movi...

Embodiment 2

[0026] see Figure 1-2 and Figure 4 , a high-efficiency paint dipping device for transformer windings, comprising a device main body 1, an air diffuser cover 2 is arranged on both sides of the device main body 1, a first motor 3 is fixedly connected to the outer end of the device main body 1, and the rotating shaft of the first motor 3 The fan blade 4 is fixedly connected to the top, and the inner side of the fan blade 4 is provided with a heating wire 5. The upper end of the equipment body 1 is provided with a lifting mechanism 6, and the lower end of the lifting mechanism 6 is provided with a paint dipping mechanism 7. The paint dipping mechanism 7 includes a fixing plate 71 , the inner side of the fixed plate 71 is fixedly connected with a support arm 72, the left end of the fixed plate 71 is fixedly connected with a second motor 73, the upper end of the support arm 72 is provided with a roller 74, and the middle part of the support arm 72 is movably connected with a secto...

Embodiment 3

[0028] see Figure 1-4 , a high-efficiency paint dipping device for transformer windings, comprising a device main body 1, an air diffuser cover 2 is arranged on both sides of the device main body 1, a first motor 3 is fixedly connected to the outer end of the device main body 1, and the rotating shaft of the first motor 3 The fan blade 4 is fixedly connected to the top, and the inner side of the fan blade 4 is provided with a heating wire 5. The upper end of the equipment body 1 is provided with a lifting mechanism 6. The lifting mechanism 6 includes a driving disc 61, and the front end of the driving disc 61 is fixedly connected with a cylindrical pin 62. The outside of the cylindrical pin 62 is movably connected with a lifting plate 63, and the rear end of the drive plate 61 is fixedly connected with an output motor. The inside of the lifting plate 63 is provided with an arc-shaped groove, and the radius of the arc-shaped groove is the same as the radius of the circular movi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com