Air pump capable of rapidly replacing diaphragm

An air pump and diaphragm technology, applied to pumps with flexible working elements, pumps, pump components, etc., can solve the problems of valve volume dust, diaphragms are easy to lose elasticity, and cannot be repaired and replaced by themselves, so as to reduce the difficulty of operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

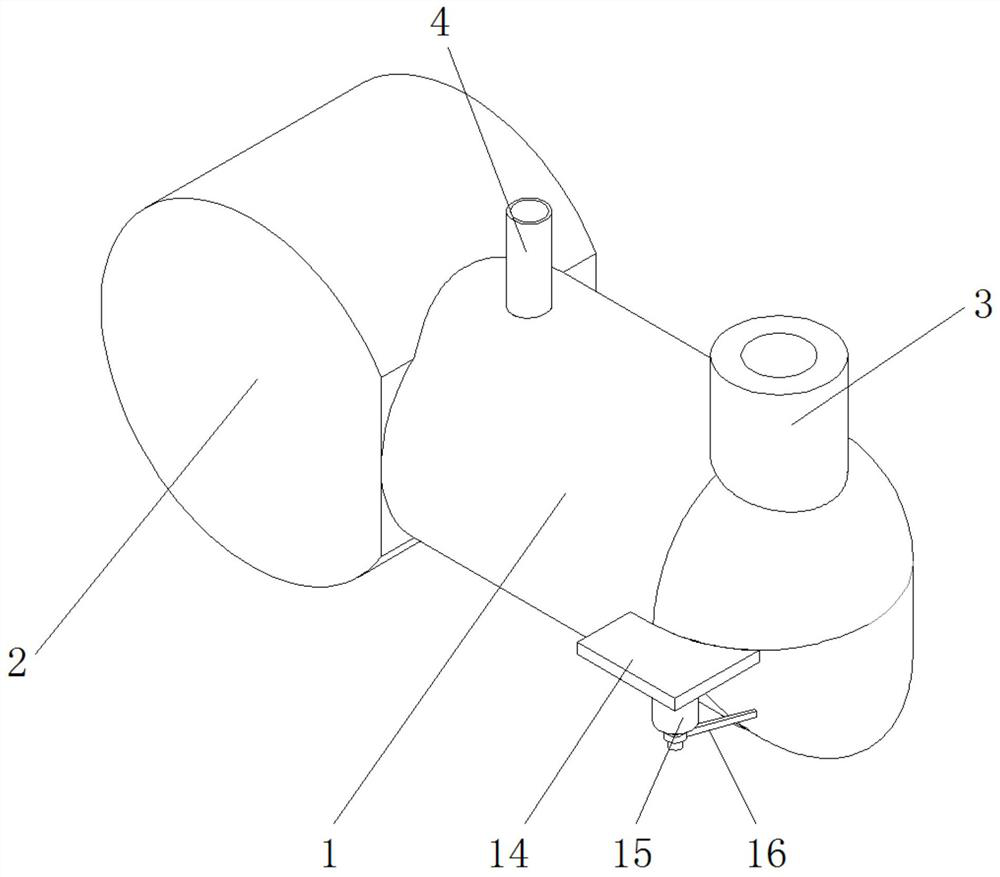

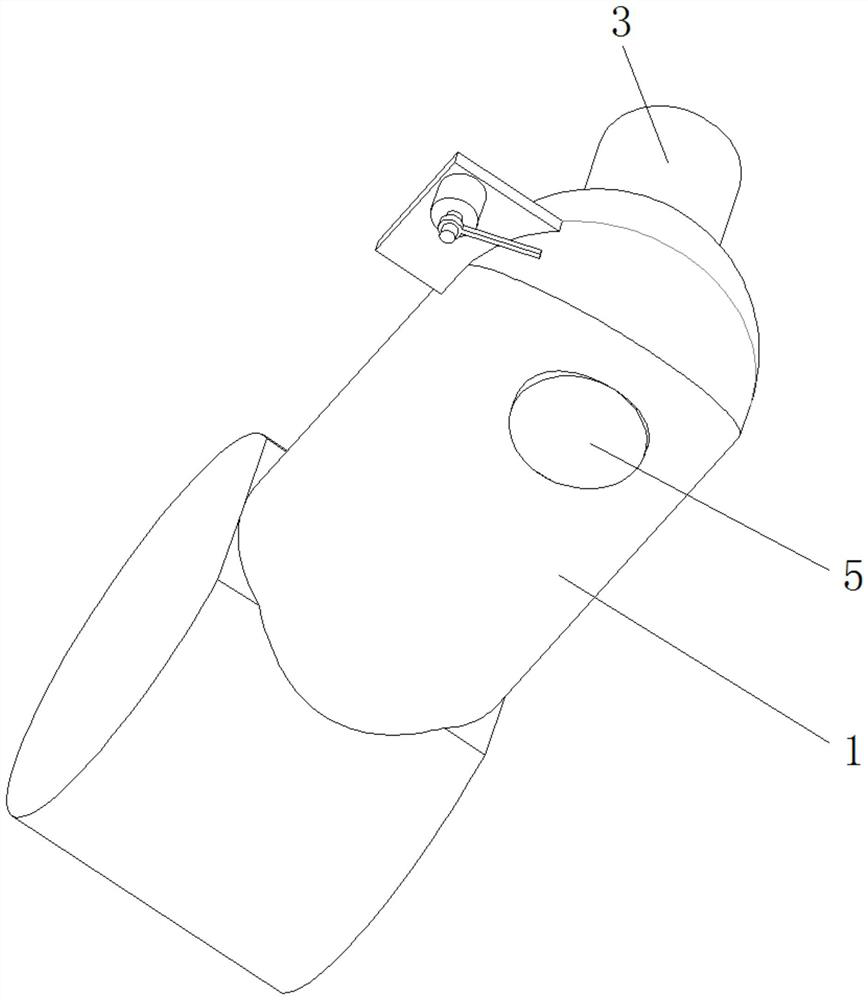

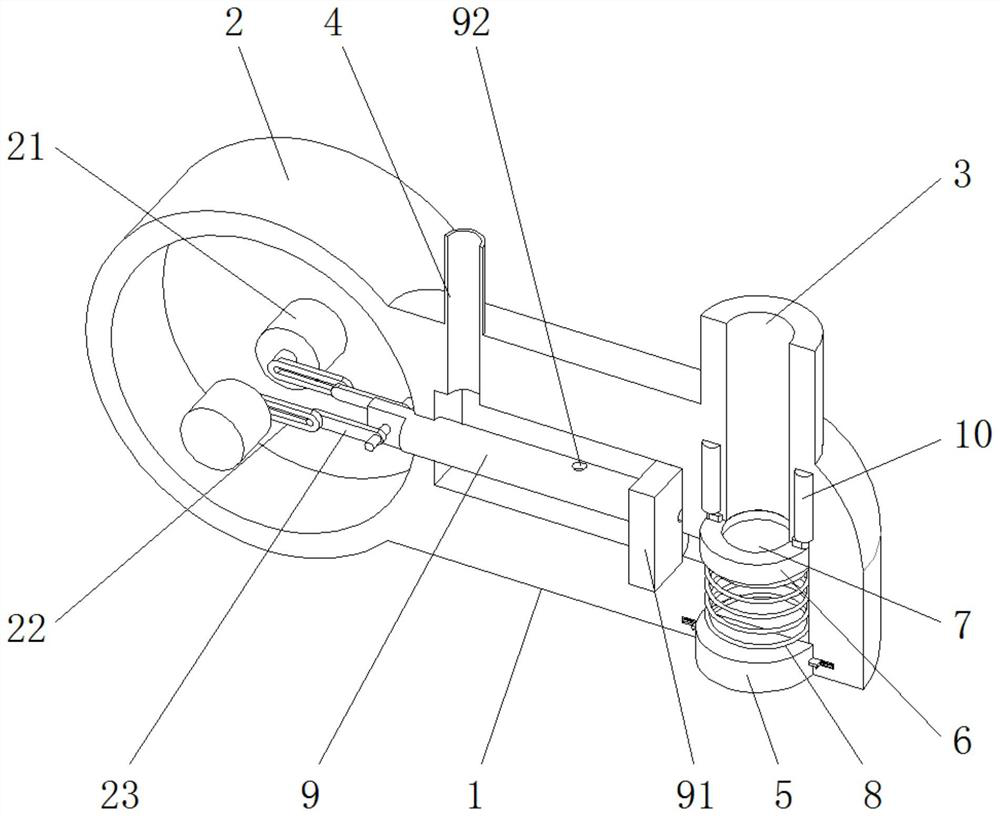

[0027] An embodiment of the present invention provides an air pump that can quickly replace the diaphragm, such as Figure 1-7 As shown, it includes an air chamber 1, and the rear end of the air chamber 1 is welded with a driving chamber 2. An air intake pipe 3 is welded on the top of the front end of the air chamber 1, and an air outlet pipe 4 is welded on the top of the rear end of the air chamber 1. An air groove is provided in the air chamber 1, and an air pipe 9 is arranged in the air groove, and a piston 91 is welded at the front end of the air pipe 9, and the piston 91 slides and fits with the air groove.

[0028] as attached Figure 4 As shown, the air inlet pipe 3 and the air outlet pipe 4 are all connected with the air groove, the air inlet pipe 3 is located in front of the air groove, and the bottom of the air chamber 1 is provided with a base plate 5 below the air inlet pipe 3 . In the intake pipe 3, a positioning ring 6 is slidably fitted, and a diaphragm 7 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com