Energy-absorbing super-hydrophobic anti-icing coating for insulators and preparation method of energy-absorbing super-hydrophobic anti-icing coating

An insulator, super-hydrophobic technology, applied in coatings, radiation-absorbing coatings, epoxy resin coatings, etc., can solve problems such as low adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

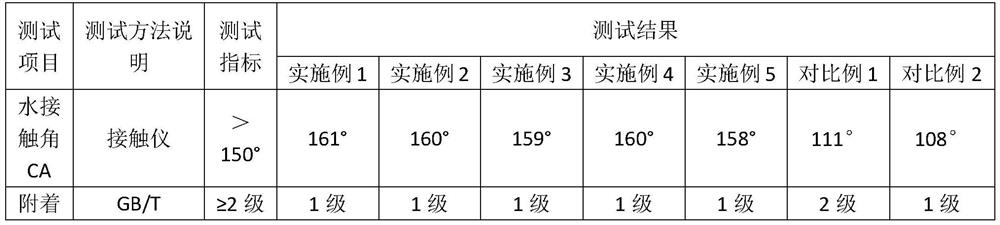

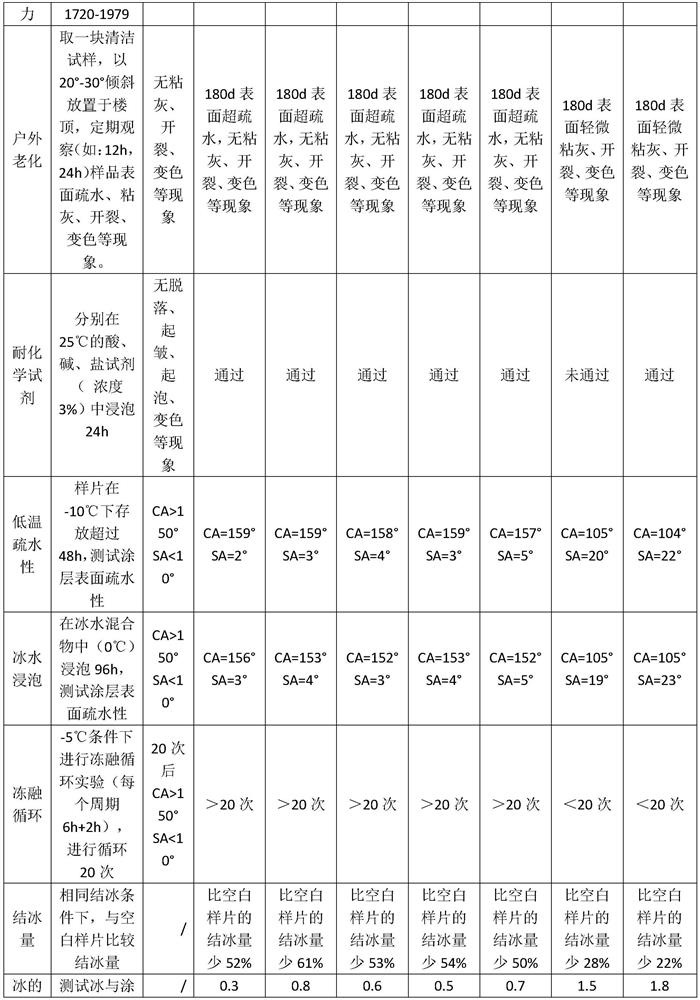

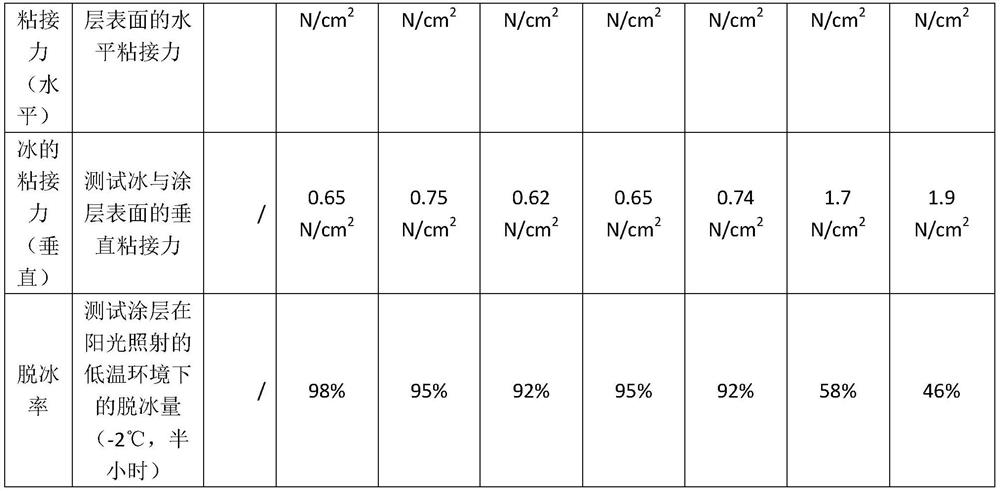

Examples

Embodiment 1

[0027] The energy-absorbing superhydrophobic anti-icing coating that present embodiment adopts comprises primer and finish paint:

[0028] The primer is composed of the following components in parts by weight: 20 parts of fluoro-silicon resin, 20 parts of acrylic resin, 15 parts of barium sulfate powder, 40 parts of butyl acetate and 5 parts of propylene glycol methyl ether acetate.

[0029] The top paint is composed of the following components in parts by weight: 5 parts of polytetrafluoroethylene powder, 2 parts of carbon black, 3 parts of titanium dioxide, and 90 parts of ethanol dispersion of modified nano silicon dioxide.

[0030] The particle size of the barium sulfate powder is 10-100 μm.

[0031] The modified nano silicon dioxide dispersion liquid is an ethanol dispersion liquid of nano modified silicon dioxide particles, the particle diameter is 100-1000nm, and the solid content is 10%.

[0032] In this embodiment, the preparation method of the energy-absorbing super...

Embodiment 2

[0038] The energy-absorbing superhydrophobic anti-icing coating that present embodiment adopts comprises primer and finish paint:

[0039] The primer is composed of the following components in parts by weight: 20 parts of fluoro-silicon resin, 20 parts of acrylic resin, 15 parts of calcium carbonate powder, 43 parts of butyl acetate and 2 parts of propylene glycol methyl ether acetate.

[0040] The top paint consists of the following components in parts by weight: 4 parts of polytetrafluoroethylene powder, 2 parts of carbon black, 2 parts of titanium dioxide, and 96 parts of ethanol dispersion of modified nano silicon dioxide.

[0041] The particle size of calcium carbonate powder is 10-100 μm.

[0042] The modified nano silicon dioxide dispersion liquid is a methanol dispersion liquid of nano modified silicon dioxide particles, the particle diameter is 100-1000nm, and the solid content is 12%.

[0043] In this embodiment, the preparation method of the energy-absorbing super-...

Embodiment 3

[0049]The energy-absorbing superhydrophobic anti-icing coating that present embodiment adopts comprises primer and finish paint:

[0050] The primer is composed of the following components in parts by weight: 20 parts of fluoro-silicon resin, 25 parts of epoxy resin, 10 parts of barite powder, 40 parts of butyl acetate and 5 parts of propylene glycol methyl ether acetate.

[0051] The top paint consists of the following components in parts by weight: 2 parts of polytetrafluoroethylene powder, 1 part of carbon black, 1 part of titanium dioxide, and 96 parts of ethanol dispersion of modified nano silicon dioxide.

[0052] The particle size of the barite powder is 10-100 μm.

[0053] The modified nano silicon dioxide dispersion liquid is a methanol dispersion liquid of nano modified silicon dioxide particles, the particle diameter is 100-1000nm, and the solid content is 13%.

[0054] In this embodiment, the preparation method of the energy-absorbing super-hydrophobic anti-icing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com