Waterborne polyurethane-polyurea dispersion resin as well as preparation method and application thereof

A water-based polyurethane and dispersion technology, applied in the field of glass fiber impregnation film-forming agent, can solve the problems of not meeting the requirements of glass fiber processing, limited number of functional groups, low proportion of active ingredients, etc., and achieve excellent film-forming properties Solvent resistance, excellent solvent resistance, effects of high strength and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

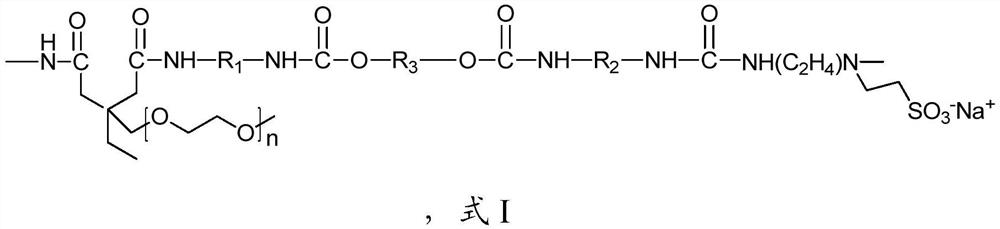

Method used

Image

Examples

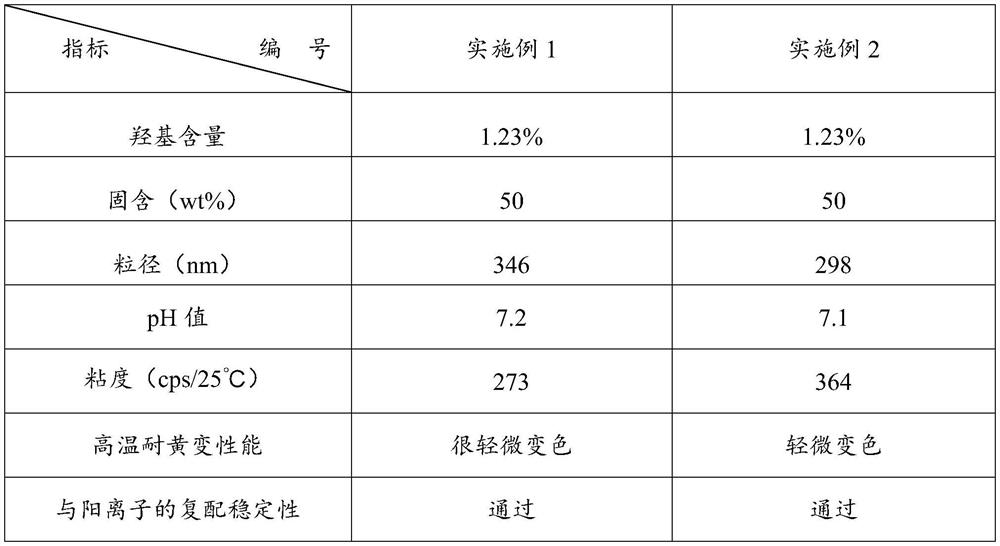

Embodiment 1

[0105] (1) Add 37.84g HDI, 50g IPDI, 23g Ymer TM N120, 240g PNA2000, 16.4g neopentyl glycol, 0.12g BiCat8108, and 37g acetone, stirred and heated to 80°C for 3 hours, reacted until the NCO in the system basically reached or approached the theoretical value, and an isocyanate-terminated prepolymer was generated;

[0106] (2) Then cool down the system to about 50-56°C, add 550g of acetone, stir evenly, maintain the temperature between 40-45°C, dissolve and dilute the materials in the system, and obtain the diluted isocyanate-terminated prepolymer;

[0107] (3) Dissolve 4g of IPDA, 4g of hydroxyethylethylenediamine and 1.6g of A95 in 40g of water, stir thoroughly to obtain an aqueous solution, and add it to the diluted isocyanate obtained in step (2) within 1 to 3 minutes In the end-capped prepolymer, maintain the system at 45-50°C for chain extension reaction for 25 minutes; pour the prepolymer prepared by the chain extension reaction into a dispersion cup, and add it under h...

Embodiment 2

[0111] (1) Add 37.84g HDI, 50g IPDI, 23g Ymer TM N120, 240g of PTMEG2000, 16.4g of neopentyl glycol, 0.12g of BiCat8108 and 37g of acetone, stirred and heated to 80°C for 3 hours of reaction until the NCO in the system basically reached or approached the theoretical value, and an isocyanate-terminated prepolymer was generated;

[0112] (2) Then cool down the system to about 50-56°C, add 550g of acetone, stir evenly, maintain the temperature between 40-45°C, dissolve and dilute the materials in the system, and obtain the diluted isocyanate-terminated prepolymer;

[0113] (3) Dissolve 4g of IPDA, 4g of hydroxyethylethylenediamine and 1.6g of A95 in 40g of water, stir thoroughly to obtain an aqueous solution, and add it to the diluted isocyanate obtained in step (2) within 1 to 3 minutes In the end-capped prepolymer, maintain the system at 45-50°C for chain extension reaction for 25 minutes; pour the prepolymer prepared by the chain extension reaction into a dispersion cup, an...

Embodiment 3

[0117] (1) Add 37.84g HDI, 50g IPDI, 23g Ymer TM N120, 240g of CMA654, 12g of neopentyl glycol, 0.12g of BiCat8108 and 37g of acetone, stirred and heated to 80°C for 3 hours of reaction until the NCO in the system basically reached or approached the theoretical value, and an isocyanate-terminated prepolymer was generated;

[0118] (2) Then cool down the system to about 50-56°C, add 550g of acetone, stir evenly, maintain the temperature between 40-45°C, dissolve and dilute the materials in the system, and obtain the diluted isocyanate-terminated prepolymer;

[0119] (3) Dissolve 4g of IPDA, 4g of hydroxyethylethylenediamine and 1.6g of A95 in 40g of water, stir thoroughly to obtain an aqueous solution, and add it to the diluted isocyanate obtained in step (2) within 1 to 3 minutes In the end-capped prepolymer, maintain the system at 45-50°C for chain extension reaction for 25 minutes; pour the prepolymer prepared by the chain extension reaction into a dispersion cup, and add...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com