Preparation method of high-activity spherical calcined coal gangue powder

A technology for calcining coal gangue with high activity, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problem of lack of synergistic consideration of particle shape control and pozzolanic activity improvement, and achieve a significant low-carbon effect , the effect of high sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

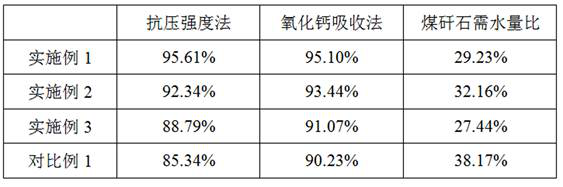

Embodiment 1

[0032]A method for producing high-activity spherical calcined coal gangue by combined jet pulverization-radio frequency plasma technology, comprising the following production steps:

[0033] (1) Jet crushing of coal gangue. Put the above-mentioned pre-mixed mixture powder into the jet crushing equipment. The main operating parameters of the jet mill are: compressed air flow rate 4L / min, installed power 20 kW, production capacity 50 kg / h , The discharge particle size is 2~60μm;

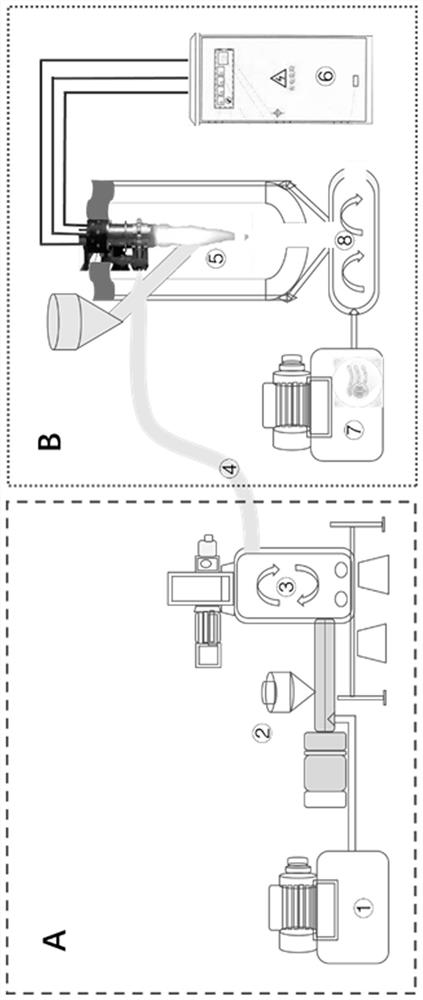

[0034] (2) RF plasma high temperature treatment, the RF plasma system consists of the following parts: RF plasma torch, RF plasma power supply, gas supply and powder feeding system, reaction chamber and collection chamber and bracket, vacuum pumping system, electrical control and Measuring systems, chillers. The operating parameters of the radio frequency plasma generation chamber are: power 50 kW, frequency 2.5 MHz, working gas is air, and the flame core temperature of the plasma generator is 900-100...

Embodiment 2

[0037] A method for producing high-activity spherical calcined coal gangue by combined jet pulverization-radio frequency plasma technology, comprising the following production steps:

[0038] (1) Preparation of raw meal: The gangue powder and red mud are weighed according to the mass ratio of 95:5 and mixed in advance.

[0039] (2) Airflow milling treatment: Put the above pre-mixed mixture powder into the airflow milling equipment. The main operating parameters of the airflow mill are: compressed air flow rate 10L / min, installed power 80 kW, production capacity 130kg / h, feed The particle size is not more than 5mm, the output particle size is 2-50μm, and the carrier gas flow is nitrogen.

[0040] (3) RF plasma high temperature treatment, the RF plasma system consists of the following parts: RF plasma torch, RF plasma power supply, gas supply and powder feeding system, reaction chamber and collection chamber and bracket, vacuum pumping system, electrical control and Measuring s...

Embodiment 3

[0043] A method for producing high-activity spherical calcined coal gangue by combined jet pulverization-radio frequency plasma technology, comprising the following production steps:

[0044] (1) Preparation of raw meal: Accurately weigh coal gangue powder, calcium carbide slag, and potassium sulfate according to the mass ratio of 92:7:1 and mix them in advance.

[0045] (2) Airflow milling treatment: Put the above pre-mixed mixture powder into the airflow milling equipment. The main operating parameters of the airflow mill are: compressed air flow rate 10L / min, installed power 100kW, production capacity 150kg / h, feed particle The diameter is not more than 5mm, the discharge particle size is 2~50μm, and the carrier airflow is air.

[0046] (3) RF plasma high temperature treatment, the RF plasma system consists of the following parts: RF plasma torch, RF plasma power supply, gas supply and powder feeding system, reaction chamber and collection chamber and bracket, vacuum pumpin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| activation index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com