Efficient machining method for complex window in thin-wall carburizing area

A carburizing zone and window technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem of poor guarantee of the dimensional accuracy and surface gloss of the processed surface, the processing parameters cannot be given too high, and the overall reduction of the tool Rigidity and other issues to achieve the effect of improving cutting stability, maintaining cutting stability, and improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Taking the complex window of the thin-walled carburizing zone of the active bevel gear as an example to introduce the invention:

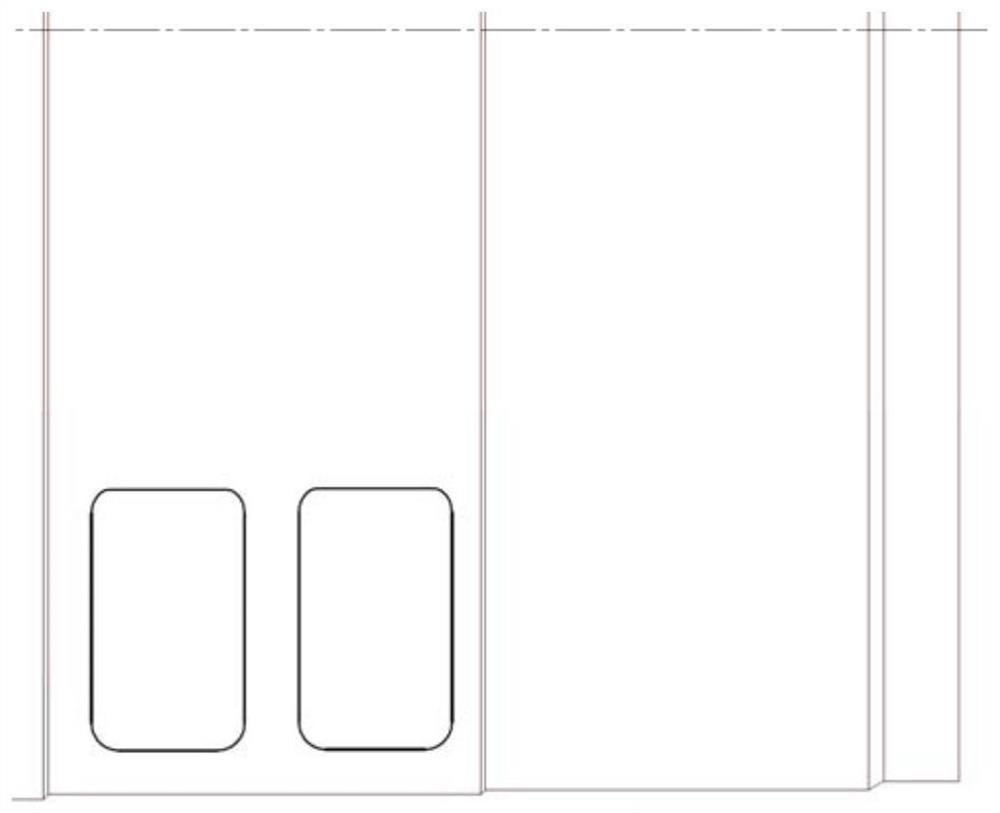

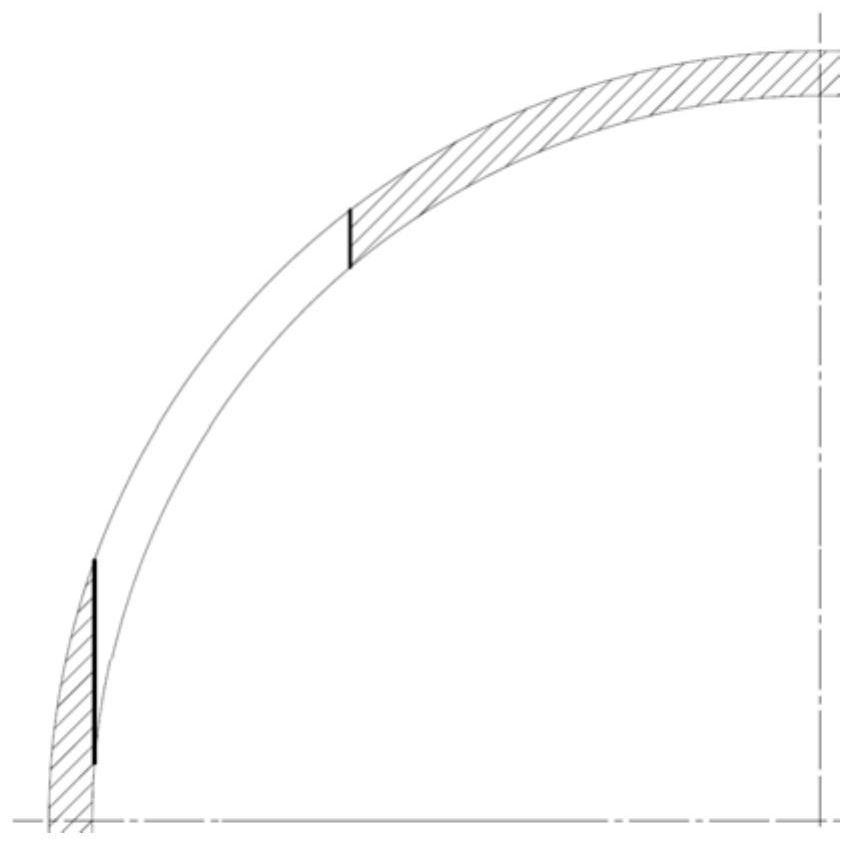

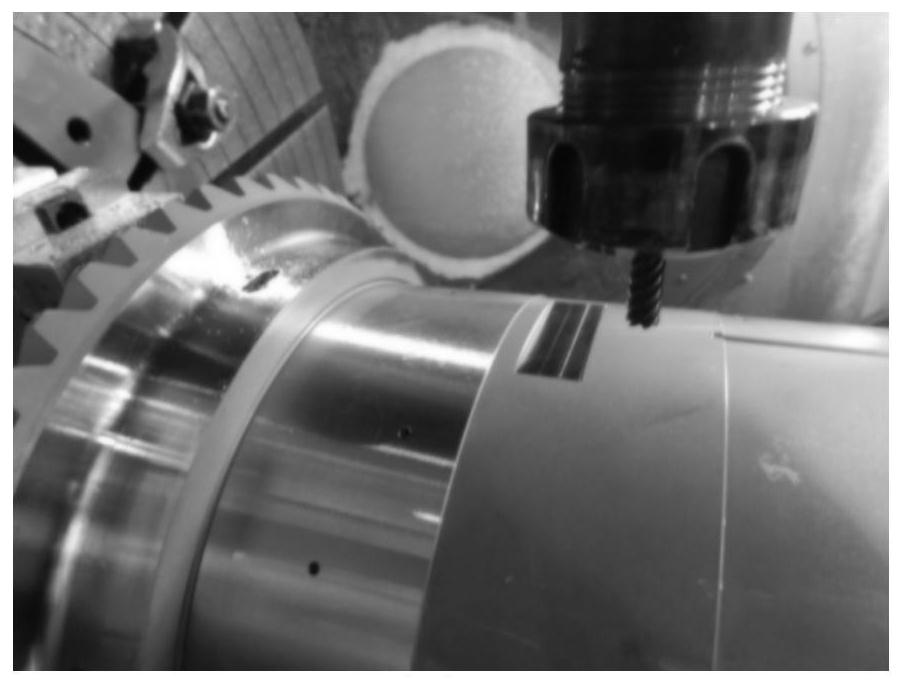

[0054] 1) Use a hard material end mill φ6 to remove material in the window surface area by plane milling, and use it as a working plane for subsequent drilling. The working plane is rectangular, with a length of 48.8mm and a width of 15mm. The programming strategy adopts the reciprocating plane milling method, the amount of cutting on one side is 0.5mm, and the cutting depth and large feed are adopted (cutting parameters: S=4000r / min, F=300mm / min) to improve the hardening material removal efficiency. The hard material end mill φ6 is a special end mill for hard material processing. The number of cutting edges is 6, which can reduce the cutting depth of each tooth per unit time, which is beneficial to protect the cutting edge of the tool, and is beneficial to the realization of durable and stable cutting. Surface gloss provides a stable and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com