Method for laser processing of CFRP material

A laser processing and laser technology, which is applied in laser welding equipment, metal processing equipment, metal material coating technology, etc., can solve the problems of difficult to achieve complex structure surface cladding, low coating deposition rate, low coating adhesion, etc. , to achieve the effects of high coating forming efficiency, uniform and dense coating, and good chip removal conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

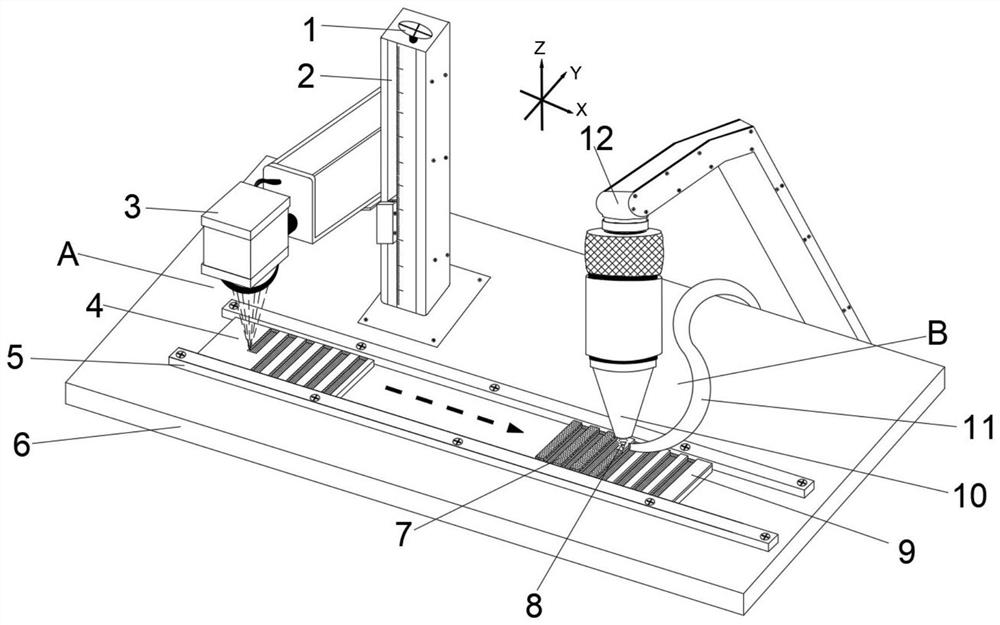

[0035] Example 1 as figure 1 , figure 2 and Figure 4 Shown, the method for laser processing CFRP material of the present invention, concrete steps are as follows:

[0036] A. Cut the polyphenylene sulfide (PPS)-based carbon fiber plate with a thickness of 3mm, a fiber content of 50%, and a unidirectional arrangement of fibers into squares of 3mm×30mm×50mm by wire cutting.

[0037] B. Pretreat the surface of CFRP plate 4 with laser degumming method. The pulse width of laser degumming is 200ns, the repetition frequency is 80KHz, the power is 100w, and the scanning speed is 2500mm / s, so that the surface carbon fiber is exposed, and the metal coating and wettability of carbon fiber;

[0038] C. Place the CFRP plate 4 that has been degummed on the fixed desktop 5, and fix it with the working table 6, and place it under the laser for laser milling and etching. Among them, the lifting axis 1 of the laser can adjust the vertical movement distance of the laser head, and the verti...

Embodiment 2

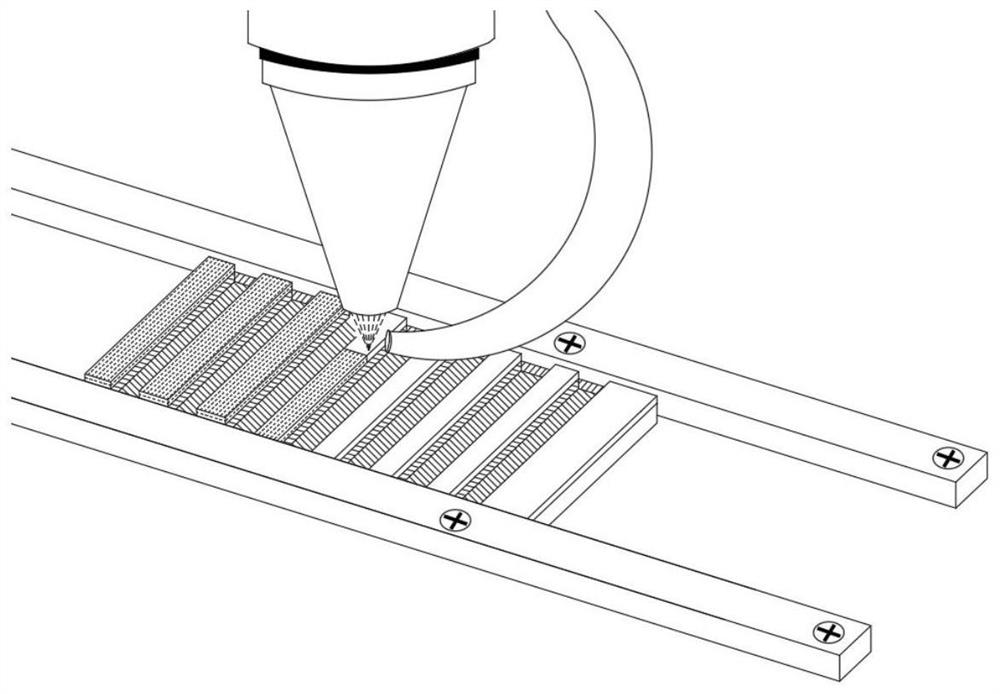

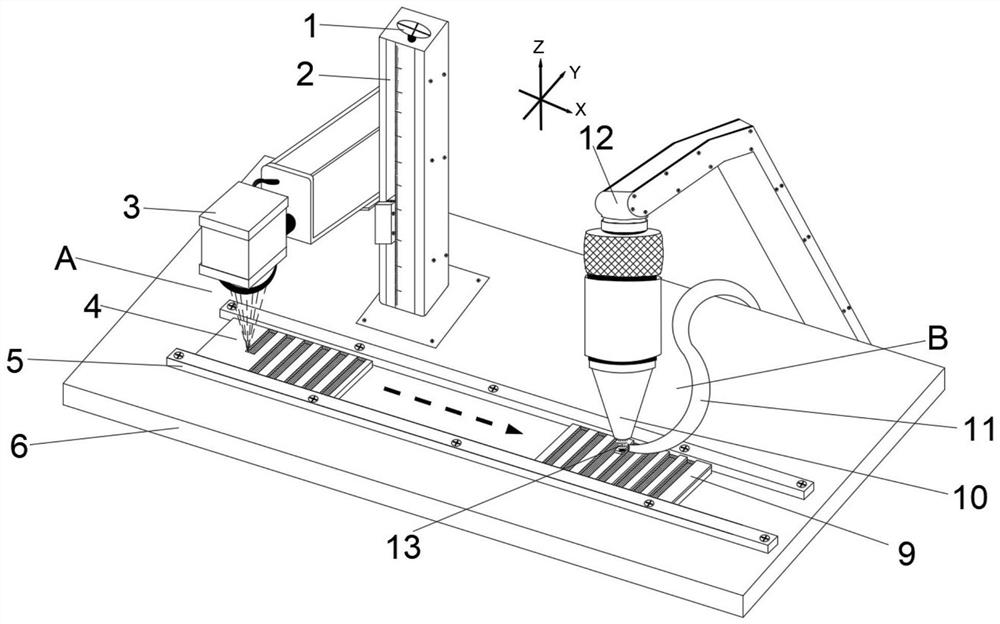

[0040] Example 2 as image 3 , Figure 4 and Figure 5 Shown, the method for laser processing CFRP material of the present invention, concrete steps are as follows:

[0041] A. Use wire cutting to cut the carbon fiber plate with epoxy resin as the matrix with a thickness of 4mm, a fiber content of 50%, and a unidirectional arrangement of fibers into squares of 4mm×30mm×50mm;

[0042] B. Pretreat the surface of the carbon fiber composite material plate by laser degumming method. The pulse width of laser degumming is 200ns, the repetition frequency is 80KHz, the power is 100w, and the scanning speed is 2500mm / s, so that the surface carbon fiber is exposed and the metal coating is increased at the same time wettability with carbon fiber;

[0043] C. Place the carbon fiber plate 4 that has been degummed on the fixed desktop 5, and fix it with the working table 6, and place it under the laser for laser milling and etching. Among them, the lifting axis 1 of the laser can adjust ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com