Black box pressure-resistant storage tank for submersible vehicle

A black box and storage tank technology, which is applied in the field of black box pressure-resistant storage tanks for submersibles, can solve problems such as seawater corrosion resistance, poor sealing performance, unfavorable arrangement and removal, and complicated opening mechanism, so as to avoid corrosion and water leakage problems, and facilitate Cable connection, the effect of meeting anti-corrosion requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

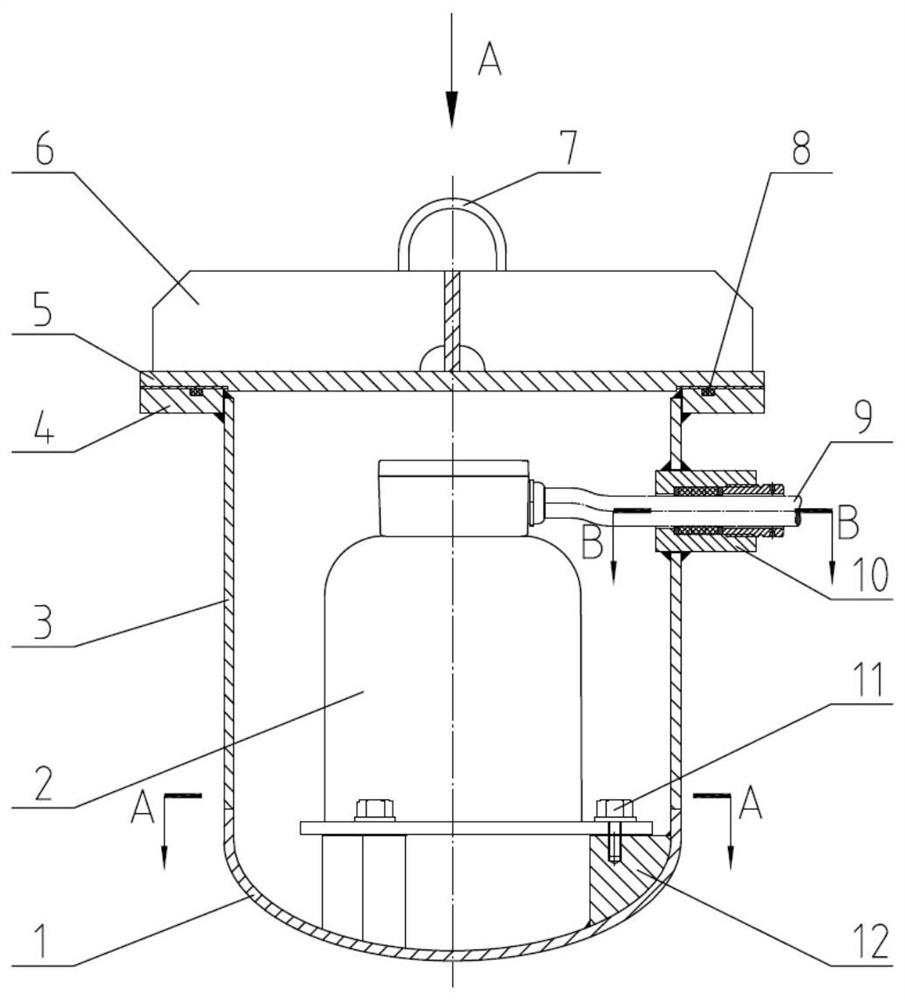

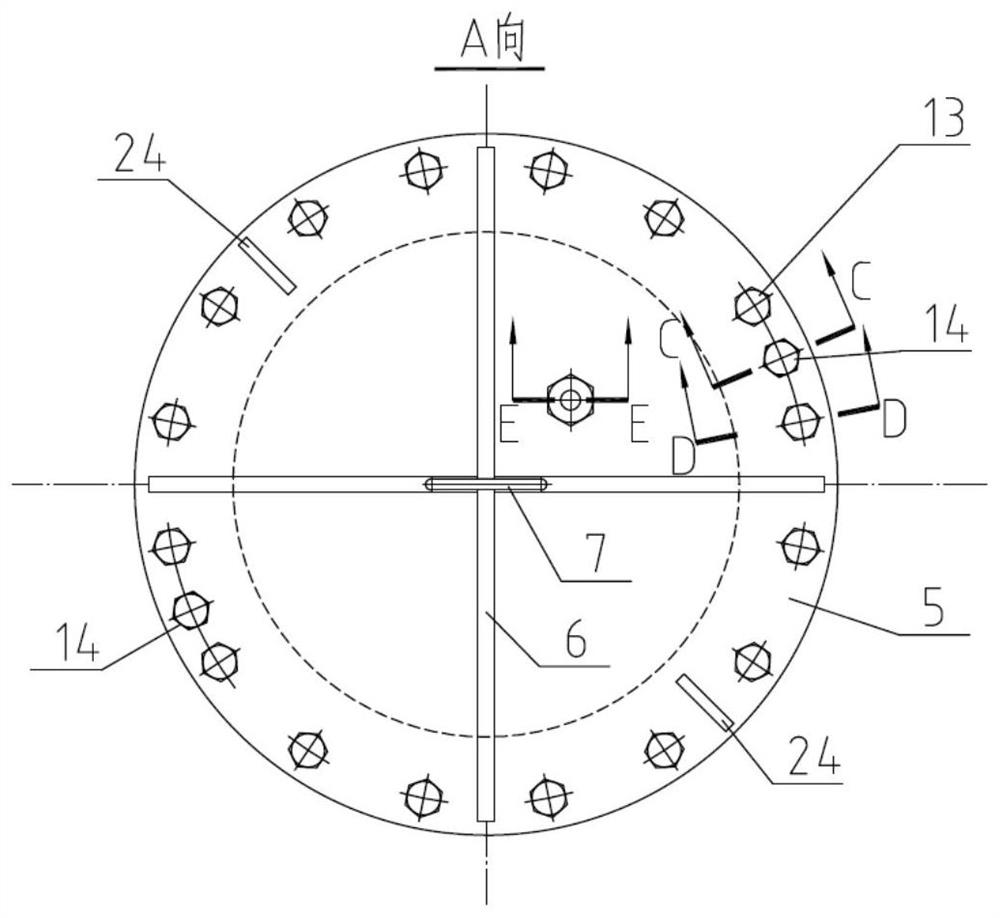

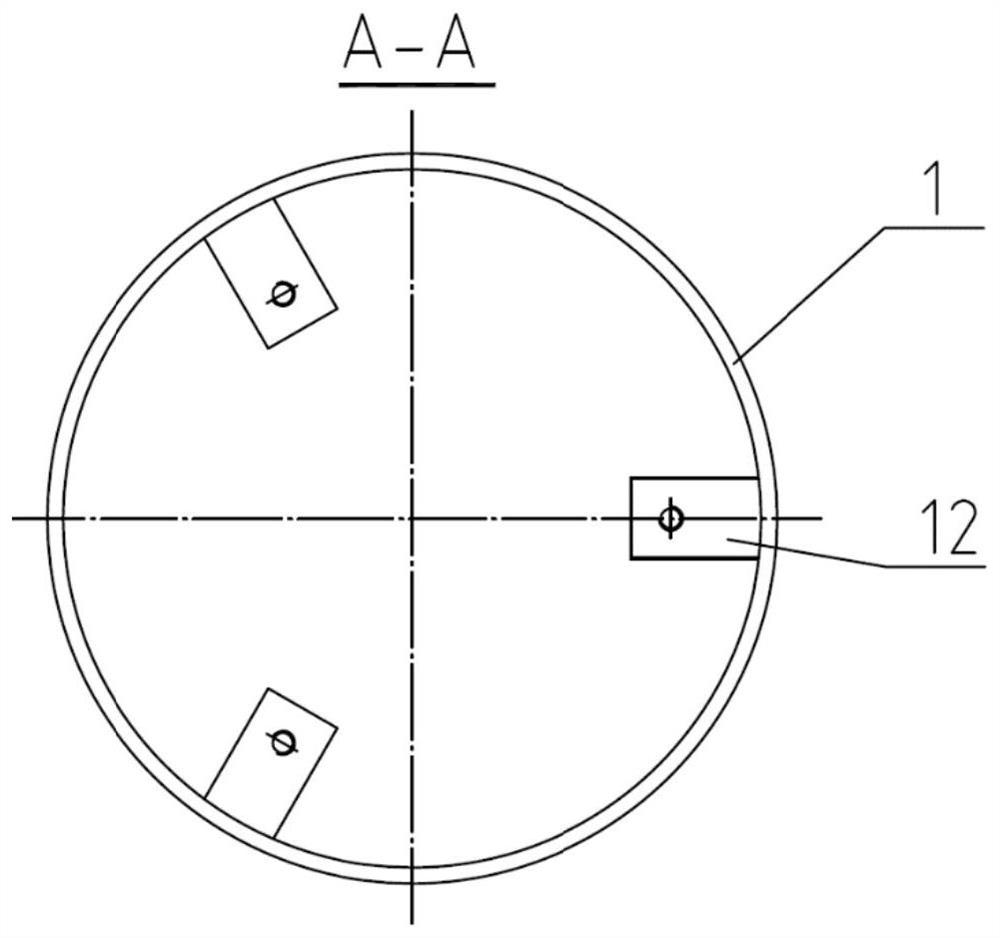

[0021] A black box pressure-resistant storage tank for a submersible, such as figure 1 and figure 2 As shown, it includes a tank body and a tank cover that can withstand the external pressure at the limit diving depth and does not undergo plastic deformation. The tank body includes a pressure-resistant cylinder 3 and elliptical heads welded to both ends of the pressure-resistant cylinder 3 respectively. Flat welding method Lan 4, the tank cover includes a cover plate 5 and a reinforcing rib 6 welded on the outer surface of the cover plate 5, a lifting lug 7 for lifting and an ear plate 24 for installing with a submersible; figure 1 and image 3 As shown, a black box base 12 is welded in the oval head 1, and the black box 2 for the submersible is installed on the black box base 12 through the black box fastener 11, as figure 1 and Figure 4 As shown, the pressure-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com