Synthetic method of metal organic framework

A technology of metal-organic framework and synthesis method, which is applied in the field of preparation of metal-organic framework materials, can solve the problems of small specific surface area, low porosity, and poor stability of MOFs materials, and achieve improved mass transfer efficiency, simplified synthesis steps, and easy interaction. The effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

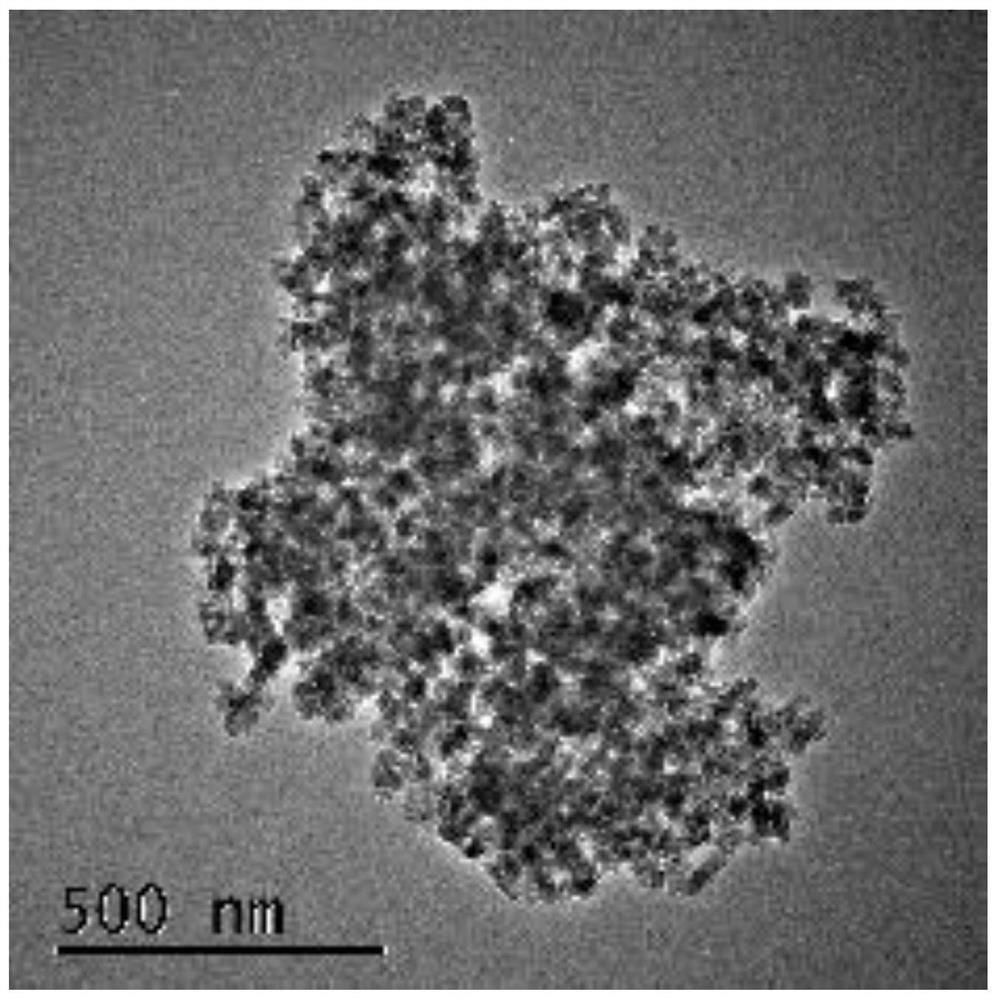

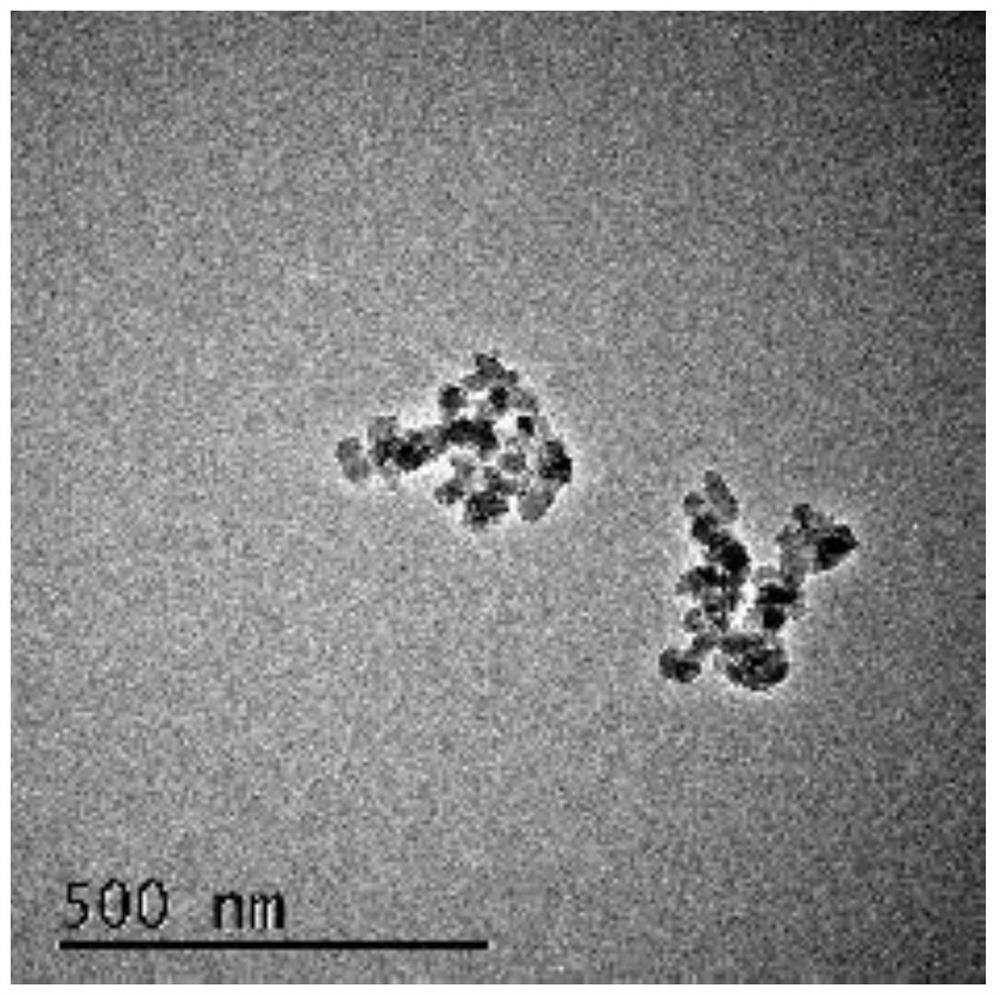

[0047] 0.23mmol of ZrCl 4 and 2.3mmol terephthalic acid were added to 2.3mmol N,N-dimethylformamide, stirred at room temperature until the solids were completely dissolved, then added 2.3mmol acetic acid, stirred evenly, added 0.23mmol water and 0.023mmol p-xylene; The above mixed solution was moved to a reaction kettle lined with polytetrafluoroethylene, and the reaction kettle was sealed, and the reaction temperature was controlled to be 100°C, and the reaction time was 10h; after the reaction was completed, the target product 1 was obtained by centrifugation, washing and drying, and its scanning Electron microscope image and nitrogen adsorption-desorption isotherm as shown in figure 1 , Figure 8 shown.

Embodiment 2

[0049] Add 0.46mmol of ZrOCl2 8H2O and 0.23mmol of terephthalic acid to 920mmol of N,N-dimethylacetamide, stir at room temperature until all the solids are dissolved, add 92mmol of formic acid, add 23mmol of water and 0.23mmol of tris Toluene, stirred evenly at room temperature; move the above mixed solution to a reaction kettle lined with polytetrafluoroethylene, seal the reaction kettle, control the reaction temperature to 120°C, and the reaction time to 12h; after the reaction, centrifuge, wash and Dried to obtain the target product 2, its scanning electron microscope picture and nitrogen adsorption-desorption isotherm are as follows figure 2 , Figure 9 shown.

Embodiment 3

[0051]Add 0.23mmol of zirconyl nitrate and 0.46mmol of terephthalic acid to 115mmol of acetonitrile, stir at room temperature until the solids are completely dissolved, add 11.5mmol of benzoic acid and stir evenly, add 11.5mmol of water and 2.3mmol of durene; then Move the above mixed solution to a reaction kettle lined with polytetrafluoroethylene, seal the reaction kettle, control the reaction temperature to 150°C, and the reaction time to 24h; after the reaction, centrifuge, wash and dry to obtain the target product 3, which Scanning electron microscope image and nitrogen adsorption-desorption isotherm as shown in image 3 , Figure 10 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com