Fly ash-based geopolymer modified coal gangue concrete block and preparation method thereof

A technology of coal gangue concrete and fly ash, which is applied in the direction of cement production, etc., can solve the problems of not very superior performance and high cost, and achieve the effects of good modification effect, repair of surface defects, and superior flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

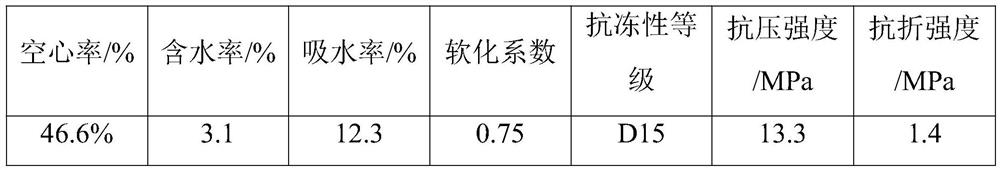

Embodiment 1

[0032] A fly ash base polymer modified coal gangue concrete block, comprising the following raw materials in parts by weight:

[0033] 80 parts of fly ash, 40 parts of slag, 180 parts of cement, 150 parts of water, 700 parts of coal gangue coarse aggregate, 300 parts of coal gangue fine aggregate, 240 parts of coal gangue sand, 40 parts of water glass, 4 parts of sodium hydroxide , 3 parts of water reducing agent.

[0034] Wherein, the method for obtaining the coal gangue coarse aggregate and coal gangue fine aggregate is as follows: the coal gangue is crushed and screened by a jaw crusher and used as block coarse and fine aggregates.

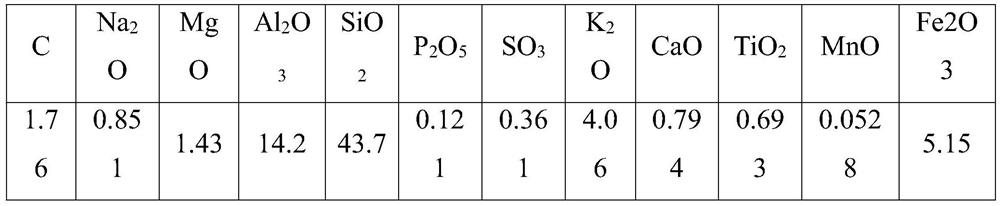

[0035] It should be noted that the coal gangue in the embodiment of the present disclosure is collected from the Zhangjiamao coal mine in northern Shaanxi.

[0036] In the scheme of the embodiment of the present disclosure, the fly ash is high-quality Class I fly ash from a power plant, and the specific surface area should be greater than 400㎡...

Embodiment 2

[0054] A fly ash base polymer modified coal gangue concrete block, comprising the following raw materials in parts by mass / weight:

[0055] 105 parts of fly ash, 45 parts of slag powder, 205 parts of cement, 175 parts of water, 785 parts of coal gangue coarse aggregate, 360 parts of coal gangue fine aggregate, 296 parts of coal gangue sand, 47 parts of water glass, 4.2 parts of sodium hydroxide parts, 3.8 parts of water reducing agent.

[0056] Wherein, the method for obtaining the coal gangue coarse aggregate and coal gangue fine aggregate is as follows: the coal gangue is crushed and screened by a jaw crusher and used as block coarse and fine aggregates.

[0057] It should be noted that the coal gangue in the embodiment of the present disclosure is collected from the Zhangjiamao coal mine in northern Shaanxi.

[0058] In the scheme of the embodiment of the present disclosure, the fly ash is high-quality Class I fly ash from a power plant, and the specific surface area shoul...

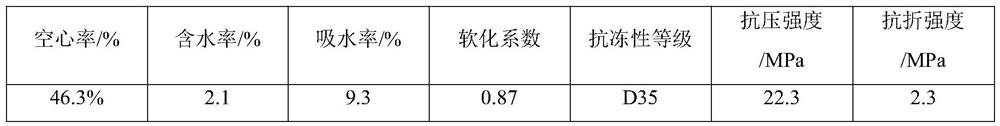

Embodiment 3

[0076] A fly ash base polymer modified coal gangue concrete block, comprising the following raw materials in parts by mass / weight:

[0077] 115 parts of fly ash, 49 parts of slag powder, 213 parts of cement, 167 parts of water, 755 parts of coal gangue coarse aggregate, 349 parts of coal gangue fine aggregate, 289 parts of coal gangue sand, 46 parts of water glass, 5.2 parts of sodium hydroxide parts, 3.4 parts of water reducing agent.

[0078] Wherein, the method for obtaining the coal gangue coarse aggregate and coal gangue fine aggregate is as follows: the coal gangue is crushed and screened by a jaw crusher and used as block coarse and fine aggregates.

[0079] It should be noted that the coal gangue in the embodiment of the present disclosure is collected from the Zhangjiamao coal mine in northern Shaanxi.

[0080] In the scheme of the embodiment of the present disclosure, the fly ash is high-quality Class I fly ash from a power plant, and the specific surface area shoul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com