Adjustable tuyere mechanism of glass tempering furnace

A glass tempering and adjustable technology, applied in the direction of glass tempering, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of affecting the effect of glass tempering, increasing the cost of tempering, and difficulty in uniform wind pressure, etc., to shorten the heat dissipation time and improve Efficiency, uniform wind pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

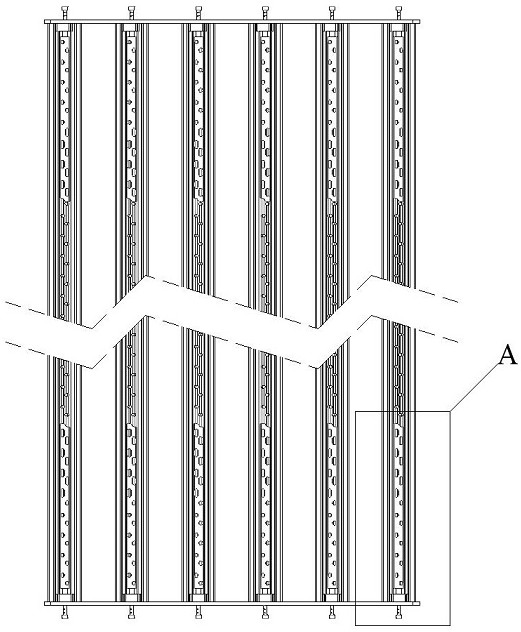

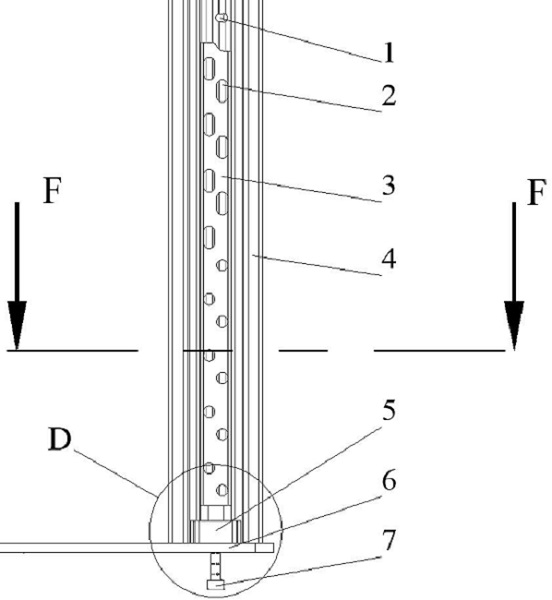

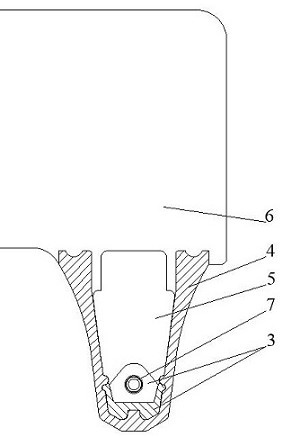

[0021] An adjustable air nozzle mechanism for a glass tempering furnace, the mechanism includes several air rows arranged up and down, the air row includes several strip-shaped air nozzles 4 arranged side by side, and the side of the strip-shaped air nozzles 4 facing the roller table of the tempering furnace A plurality of air outlet holes 1 of strip-shaped air nozzles are provided, and a tuyere inner sealing plate 3 and a tuyere plug 5 are installed inside each two ends of each strip-shaped air nozzle 4, and the tuyere plug 5 is fixed on the strip-shaped The two ends of the air nozzle 4 prevent air leakage from the gap between the two ports of the strip air nozzle 4. The perforated surface of the air nozzle inner sealing plate 3 is parallel to the perforated surface of the strip air nozzle 4. The air nozzle inner sealing plate 3 can translate or slide inside the strip air nozzle 4 to control the air outlet of the strip air nozzle The opening and closing quantity of 1 changes ...

Embodiment 2

[0023] The screw 7 passes through the wind row sealing plate 6 and the tuyere plug 5, and is connected with the tuyere inner sealing plate 3, and controls the translation distance of the tuyere inner sealing plate 3 inside the strip tuyere 4 according to the penetration depth of the screw 7, Adjust the number of aligned air outlet holes 2 on the inner sealing plate of the air nozzle and air outlet holes 1 of the strip air nozzle. If the air outlet hole 2 of the inner sealing plate of the air nozzle and the air outlet hole 1 of the strip air nozzle are not aligned, it is called the first gear, such as figure 2 , 4 , the first gear is suitable for blowing and cooling the smallest size glass; the air nozzle inner seal plate outlet hole 2 has a group of holes aligned with the strip air nozzle outlet hole 1, which is called the second gear, such as Figure 5 , 6 Compared with the first gear, the distance of a group of holes is enlarged in the second gear; the air outlet hole 2 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com