Six-station rotating disc type sand blasting machine

A turntable type, sandblasting machine technology, applied in the field of sandblasting machines, can solve the problems of high labor intensity, time-consuming and laborious, and reduce the service life of equipment, so as to increase the scope of use, improve the sandblasting effect, and increase the sandblasting effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

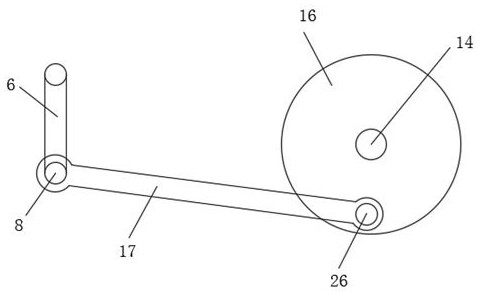

[0027] See Figure 1-9 , For example, a six-position rotary blasting machine embodiment of the present invention, comprises a housing 1, the housing 1 defines a blasting cartridge 2 is rotated, the upper sides symmetrically blasting cartridge 2 is mounted inside the crank 5, the crankshaft 5 includes a connecting section 7 and a support section 6, the crank 56 is rotatably connected to both sides of the upper housing 1 by a supporting section, there is a rack mounted on the connecting section 9, 9 fixedly mounted on the rack with a plurality of blasting guns 10, blasting guns 10 are connected to the air hose 12 and the sand feeding hose 11, one end segment 7 is provided with a connection end 8 extends, outside the upper case 1 is attached to the motor 13, the motor 13 is connected to the output terminal the drive shaft 14, the drive shaft 14 projects into the interior of the housing 1 and the runner 16 is attached to the eccentric wheel 16 is provided on the eccentric pin 26, eccen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com