Al-P-O series catalyst as well as preparation method and application thereof

A catalyst, al-p-o technology, used in chemical instruments and methods, physical/chemical process catalysts, dehydration of hydroxyl-containing compounds to prepare ethers, etc., can solve the problems of low selectivity of o-hydroxyphenethyl ether, etc. High product selectivity and the effect of avoiding aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a kind of preparation method of Al-P-O series catalyst, comprises the following steps:

[0028] mixing a water-soluble aluminum salt, a water-soluble phosphorus-containing compound, silica microspheres, an organic complexing agent, a pH regulator and water to obtain a mixed solution, aging the mixed solution, drying the solid product obtained by the aging, To obtain a catalyst precursor, the molar ratio of the phosphorus element in the water-soluble phosphorus-containing compound to the aluminum element of the water-soluble aluminum salt is ≤2:1; the pH value of the mixed solution is 5.5-6, and the silicon dioxide micro The ball is amorphous;

[0029] The catalyst precursor is calcined to remove the organic complexing agent to obtain the Al-P-O catalyst.

[0030] In the present invention, unless otherwise specified, the raw materials used are commercially available products well known to those skilled in the art.

[0031] In the present inventio...

Embodiment 1

[0069] Get 42.72g of anhydrous aluminum chloride to prepare 2mol / L aluminum chloride aqueous solution, add 12g of amorphous silicon dioxide microspheres (particle diameter is 5mm) and 8.16g of glucose and continue to stir;

[0070] Dissolve ammonium dihydrogen phosphate in 125mL ammonia water (10wt.%) and keep stirring, wherein the molar ratio of phosphate ion to aluminum ion is 1:1;

[0071] The solutions obtained in the above steps were mixed and continuously stirred, and stood at 80°C for 24 hours to obtain the aged material;

[0072] Heat the aged material at 80°C until the water evaporates to dryness and dry it in a drying oven at 100°C to obtain a solid material;

[0073] The solid material was calcined at 500°C for 6h to obtain an Al-P-O catalyst.

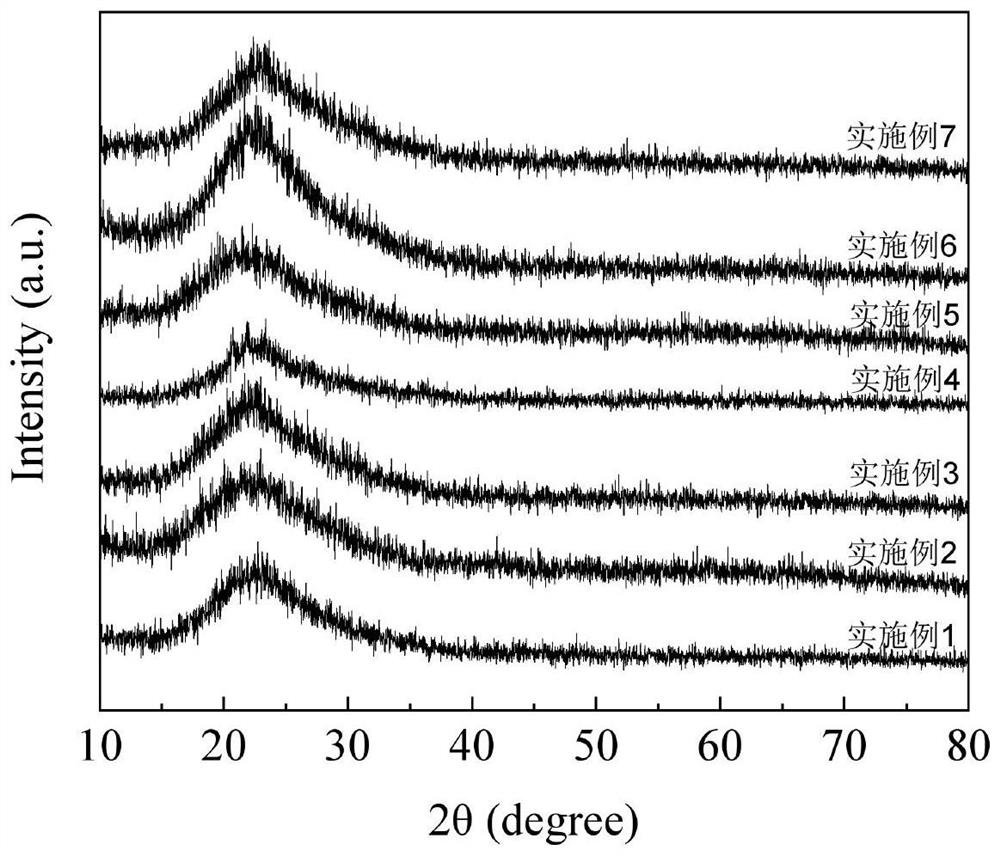

[0074] figure 1 Be the XRD spectrogram of the product obtained in this embodiment, by figure 1 It can be seen that the XRD pattern of the product prepared in this example has no obvious diffraction peak of aluminum-phosph...

Embodiment 2

[0077] Get 42.72g of anhydrous aluminum chloride to prepare 2mol / L aluminum chloride aqueous solution, add 24g of amorphous silicon dioxide microspheres (particle diameter is 5mm) and 8.16g of glucose and continue to stir;

[0078] Dissolve ammonium dihydrogen phosphate in 125mL ammonia water (10wt.%) and keep stirring, wherein the molar ratio of phosphate ion to aluminum ion is 1:1;

[0079] The solutions obtained in the above steps were mixed and continuously stirred, and stood at 80°C for 24 hours to obtain the aged material;

[0080] Heat the aged material at 80°C until the water evaporates to dryness and dry it in a drying oven at 100°C to obtain a solid material;

[0081] The solid material was calcined at 500°C for 6h to obtain an Al-P-O catalyst.

[0082] figure 1 Be the XRD spectrogram of the product obtained in this embodiment, by figure 1 It can be seen that the XRD pattern of the product prepared in this example has no obvious diffraction peak of aluminum-phosph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com