Mode converter from rectangular waveguide TE10 mode to circular waveguide rotating TE11 mode

A technology of mode converter and rectangular waveguide, which is applied in the field of millimeter wave and terahertz devices, can solve the problems that the circular polarization mode cannot be directly obtained, large processing and assembly errors, large structural size, etc., and achieves low processing and assembly difficulty and easy processing High production and conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

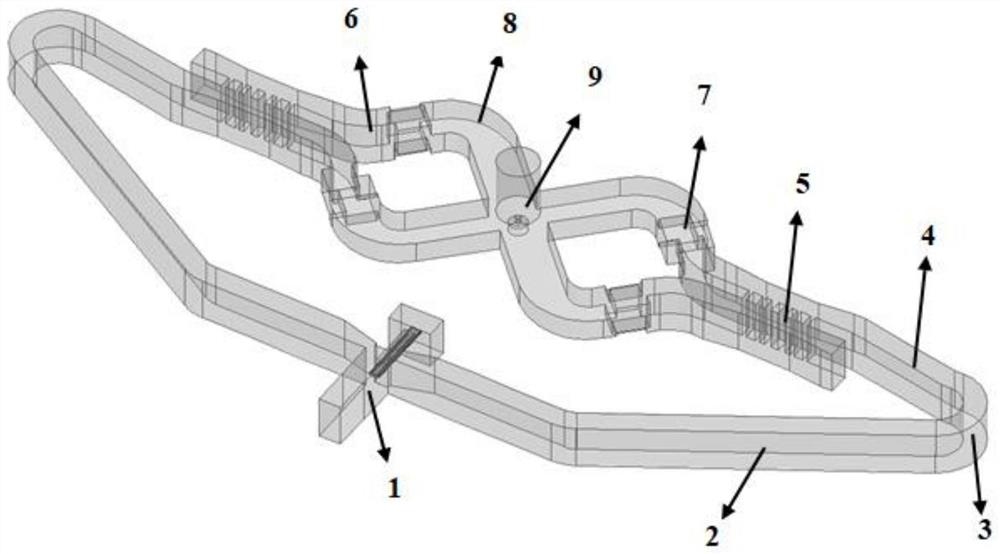

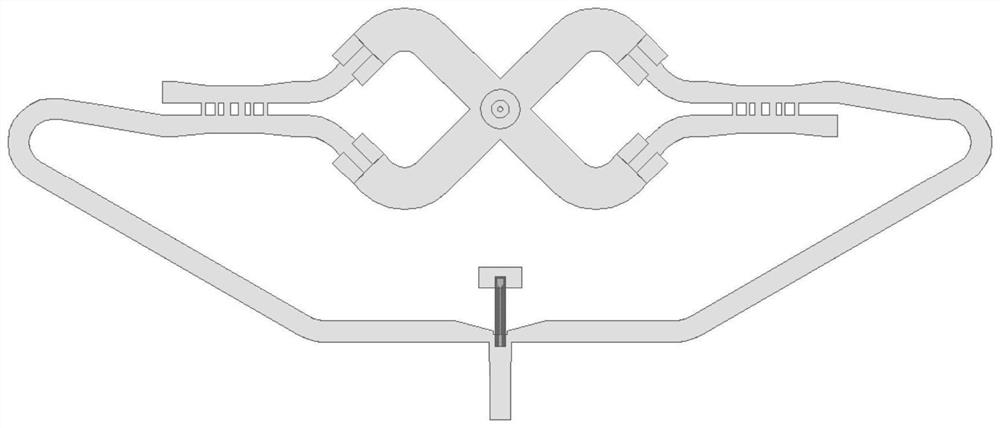

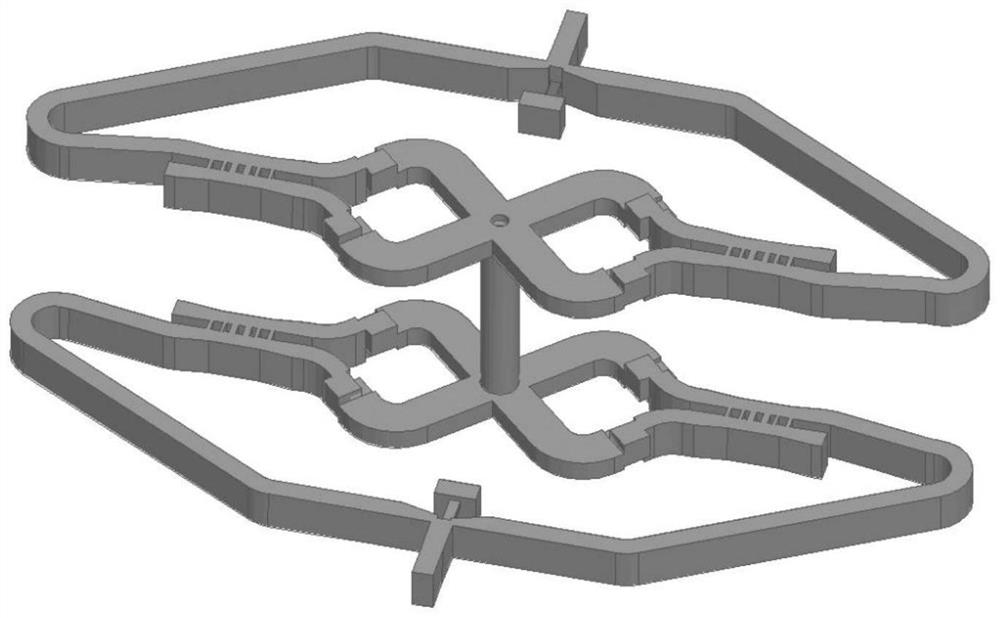

[0026] This embodiment provides a mode converter from a rectangular waveguide TE10 mode to a circular waveguide rotating TE11 mode with a center frequency of 220 GHz, the structure is as follows figure 1 and figure 2 As shown, it includes a coplanar magic T structure 1, two bent waveguides, two 3dB couplers 5, four 45° arc bent waveguides 6, four 90° waveguide twisters 7, and four 90° arcs curved waveguide 8 and a 4-way combiner 9 .

[0027] The coplanar magic T structure 1 includes a rectangular waveguide input port, a first rectangular waveguide output port, a second rectangular waveguide output port and an isolation port using a microstrip probe output, the first rectangular waveguide output port and the second rectangular waveguide output port The ports are respectively connected to the input end of the corresponding 3dB coupler 5 by bending 180° through the corresponding bent waveguide, and the bent waveguide is composed of a long inclined waveguide 2, a 150° circular a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com