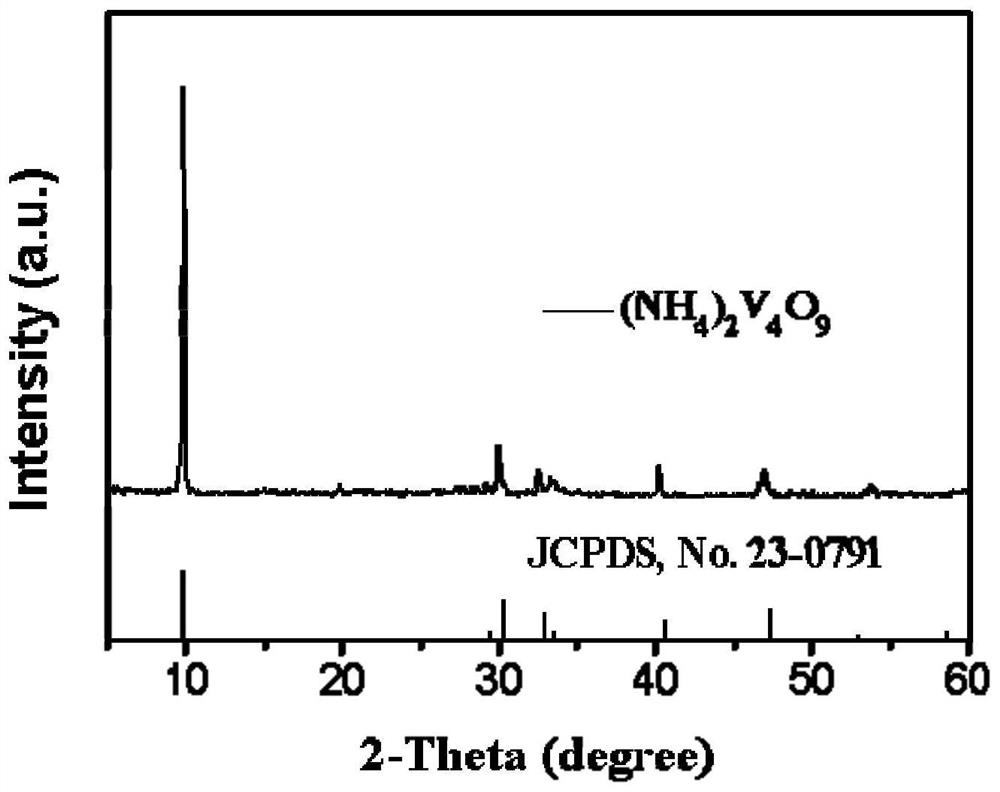

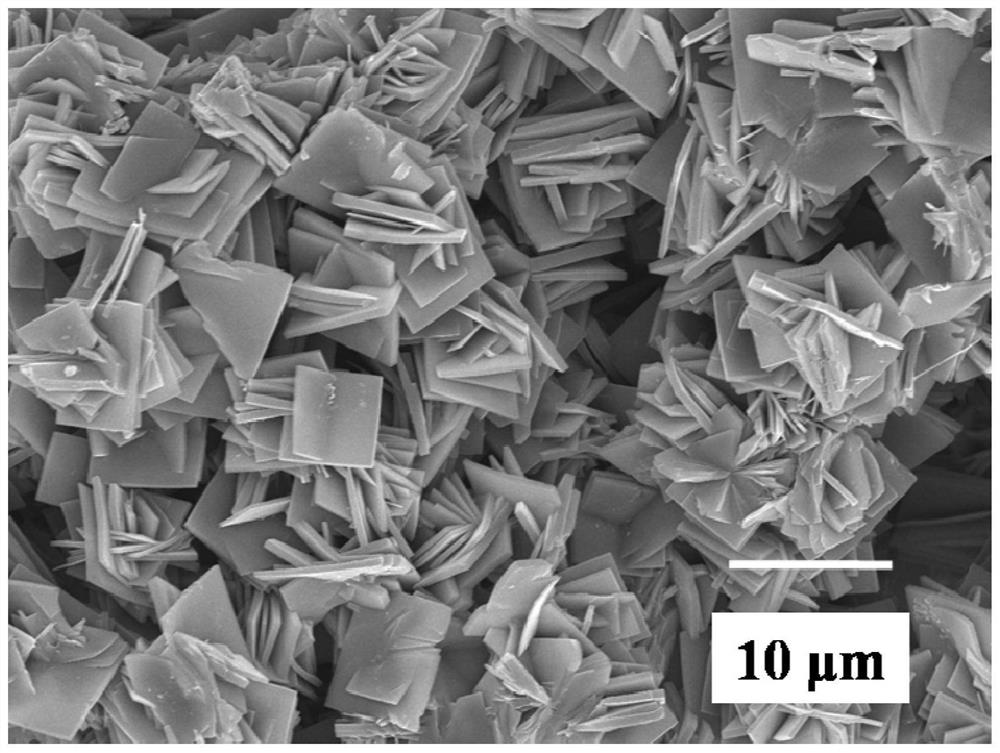

Preparation method of flaky (NH4) 2V4O9 flexible zinc ion battery electrode material

A zinc-ion battery and electrode material technology, applied in battery electrodes, active material electrodes, positive electrodes, etc., can solve the problems of rapid electrochemical performance decay, shedding, active material cracking, etc., achieving low cost, increasing contact area, Low environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1, the NH 4 VO 3 Dissolve evenly in a mixed solvent of ethylene glycol and water at a volume ratio of 1:1 at 40°C to obtain NH 4 + NH at a concentration of 0.1mol / L 4 VO 3 Solution, marked as A solution;

[0029] Step 2, take 60ml of A solution and add 0.5mL dodecyl dimethyl betaine to it, then adjust the pH to 4 with 0.5mol / L hydrochloric acid solution to obtain B solution;

[0030] Step 3: Alternately wash the carbon cloth of the flexible base material with acetone and distilled water to remove dust and impurities, then soak it in 0.5mol / L hydrochloric acid solution, dry it after washing with distilled water, and then completely immerse the flexible base material in the above B solution , and then ultrasonically react for 1h at an ultrasonic power of 200W;

[0031] Step 4, according to the filling ratio of 70%, place the B solution soaked in the flexible base material in a reaction kettle lined with polytetrachloroethylene, and react at a hydrothermal tempe...

Embodiment 2

[0035] Step 1, the NH 4 VO 3Dissolve evenly in a mixed solvent of ethylene glycol and water at a volume ratio of 1:1 at 50°C to obtain NH 4 + NH at a concentration of 0.05mol / L 4 VO 3 Solution, marked as A solution;

[0036] Step 2, take 60ml of A solution and add 0.8mL dodecyl dimethyl betaine to it, then adjust the pH to 2 with 0.2mol / L hydrochloric acid solution to obtain B solution;

[0037] Step 3: Alternately wash the carbon paper sheet of the flexible substrate material with acetone and distilled water to remove dust and impurities, then soak it in a 1mol / L hydrochloric acid solution, dry it after cleaning with distilled water, and then completely immerse the flexible substrate material in the above B solution , and then ultrasonically react at an ultrasonic power of 200W for 0.5h;

[0038] Step 4, according to the filling ratio of 50%, place the B solution soaked in the flexible base material in a reaction kettle lined with polytetrachlorethylene, and react at a ...

Embodiment 3

[0041] Step 1, the NH 4 VO 3 Dissolve evenly in a mixed solvent of ethylene glycol and water at a volume ratio of 1:1 at 50°C to obtain NH 4 + NH with a concentration of 0.18mol / L 4 VO 3 Solution, marked as A solution;

[0042] Step 2, take 60ml of A solution and add 1.2mL dodecyl dimethyl betaine to it, then adjust the pH to 3 with 0.8mol / L hydrochloric acid solution to obtain B solution;

[0043] Step 3: Alternately wash the carbon cloth of the flexible base material with acetone and distilled water to remove dust and impurities, then soak it in 0.4mol / L hydrochloric acid solution, dry it after washing with distilled water, and then completely immerse the flexible base material in the above B solution , and then ultrasonically react for 1.5h at an ultrasonic power of 300W;

[0044] Step 4, according to the filling ratio of 60%, place the B solution soaked in the flexible base material in a reaction kettle lined with polytetrachlorethylene, and react at a hydrothermal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com