Preparation method of CoMo2S4/foamed nickel supercapacitor electrode material

A technology of supercapacitors and electrode materials, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double-layer capacitors, etc., can solve the problems of energy density gap, cycle stability failing to reach its theoretical cycle life, etc., and achieve high conductivity, The effect of shortening the charge transfer path and simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) The size of a nickel 5 × 1 cm by 2 M hydrochloric acid, respectively, washed with ethanol and deionized water, ultrasonic, vacuum dried standby;

[0029] (2) Weigh 3 mmolCo (NO 3 ) 2 · 6h 2 O was dissolved in 50 mL of deionized water, sufficiently stirred at room temperature for 10 min, to give a pink solution; Weigh 3 mmolNa 2 MOO 4 · 7h 2 O and 5 mmolCO (NH 2 ) 2In the pink solution added to the above obtained, it is vigorously stirred for 20 min to obtain a uniform solution, spare;

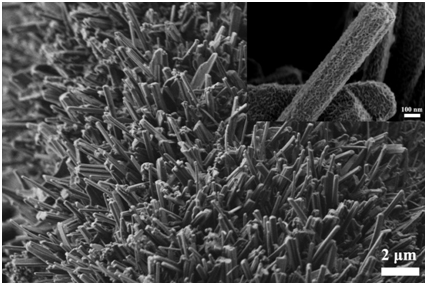

[0030] (3) The foam nickel of step (1) and the solution of step (2) are transferred to the polytetrafluoroethylene liner, and after sealing 140 ° C, the reaction is 12 h, naturally cooled to room temperature, collect the reaction. The foam nickel with the product is used to clean three times with deionized water and anhydrous ethanol, dry after drying. 4 / Foam nickel, spare;

[0031] (4) COMOo obtained by step (3) 4 / NF is placed in the polytetrafluoroethylene liner, adding 50 ml of 0....

Embodiment 2

[0033] (1) Size of 5 × 1 cm foam nickel was washed with 2 M hydrochloric acid, anhydrous ethanol and deionized water.

[0034] (2) Weigh 3 mmolco (NO 3 ) 2 · 6h 2 O Soluble in 50 ml deionized water, stirred at room temperature for 10 min to give a pink solution; weigh 3 mmolna 2 MOO 4 · 7h 2 O and 5 mmolco (NH 2 ) 2 In the pink solution added to the above obtained, it is vigorously stirred for 20 min to obtain a uniform solution, spare;

[0035] (3) The foam nickel of step (1) and the solution of step (2) are transferred to the polytetrafluoroethylene liner, and after sealing 140 ° C, the reaction is 12 h, naturally cooled to room temperature, collect the reaction. The foam nickel with the product is used to clean three times with deionized water and anhydrous ethanol, dry after drying. 4 / Foam nickel, spare;

[0036] (4) COMOo obtained by step (3) 4 / Nf is placed in the polytetrafluoroethylene liner, adding 50 ml of 0.01 m of thioacetamide solution. After sealed, the reaction k...

Embodiment 3

[0038] (1) Size of 5 × 1 cm foam nickel was washed with 2 M hydrochloric acid, anhydrous ethanol and deionized water.

[0039] (2) Weigh 3 mmolco (NO 3 ) 2 · 6h 2 O Soluble in 50 ml deionized water, stirred at room temperature for 10 min to give a pink solution; weigh 3 mmolna 2 MOO 4 · 7h 2 O and 5 mmolco (NH 2 ) 2 In the pink solution added to the above obtained, it is vigorously stirred for 20 min to obtain a uniform solution, spare;

[0040] (3) The foam nickel of step (1) and the solution of step (2) are transferred to the polytetrafluoroethylene liner, and after sealed, it is placed in a temperature of 140 ° C for 12h. Naturally, after cooling to room temperature, after collecting the reaction The foam nickel of the product is cleaned with deionized water and anhydrous ethanol, and after drying, get Comoo 4 / Foam nickel, spare;

[0041] (4) COMOo obtained by step (3) 4 / Nf is placed in a polytetrafluoroethylene liner, and 50 ml of 0.01 m of thioacetamide solution is added....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com