Magnetic powder liquid sealing device with fluid dynamic pressure back conveying function

A magnetic fluid sealing, magnetic source technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve problems such as loss and leakage, and achieve the effect of avoiding partial loss and zero leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

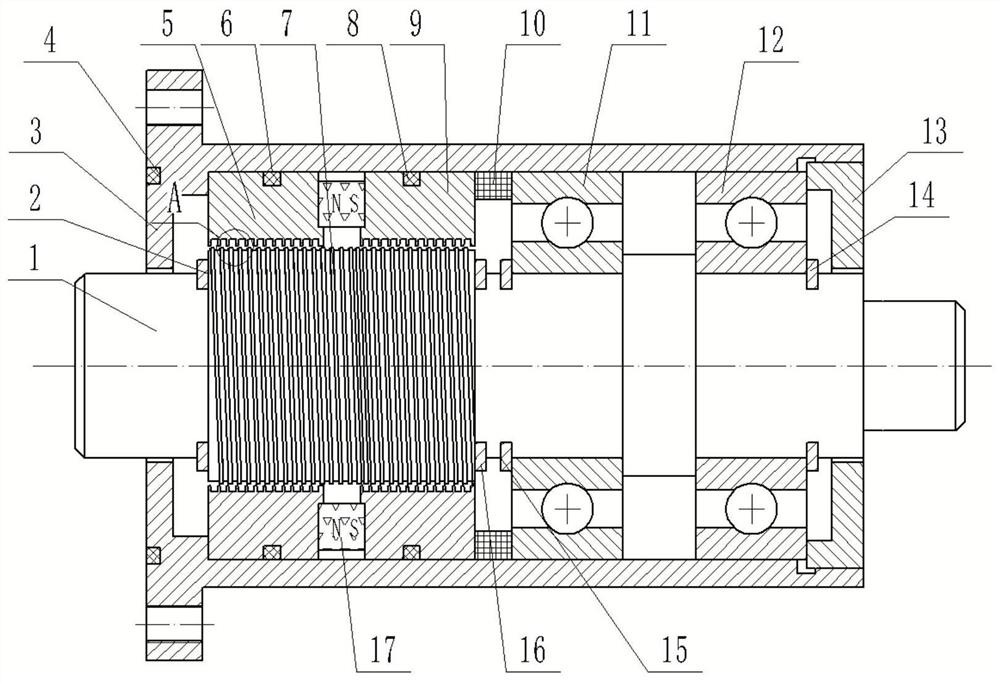

[0019] Such as figure 1 As shown, a magnetic powder sealed liquid device with hydrodynamic pressure reverse input includes a main shaft 1, a left sleeve retaining ring 2, a casing 3, an end face sealing O-ring 4, a left pole shoe 5, and a left pole shoe O-ring 6 , Spiral groove bushing 7, right pole shoe O-ring 8, right pole shoe 9, magnetic isolation ring 10, left bearing 11, right bearing 12, thread seal end cover 13, right bearing elastic retaining ring 14, left bearing elastic stop Circle 15, axle sleeve right retaining ring 16, magnetic source permanent magnet 17.

[0020] In this embodiment, the installation and working methods of the magnetic fluid sealing device for filtering magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com