Bamboo-wood-based gas diffusion catalytic electrode and application thereof

A catalytic electrode and gas diffusion technology, which is applied in the field of catalysis, can solve the problems of increasing electrode impedance, not being able to realize the utilization of the original structure of biomass, and increasing binders, etc., and achieve simple preparation methods, high-current carbon dioxide electrolysis, and wide application foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

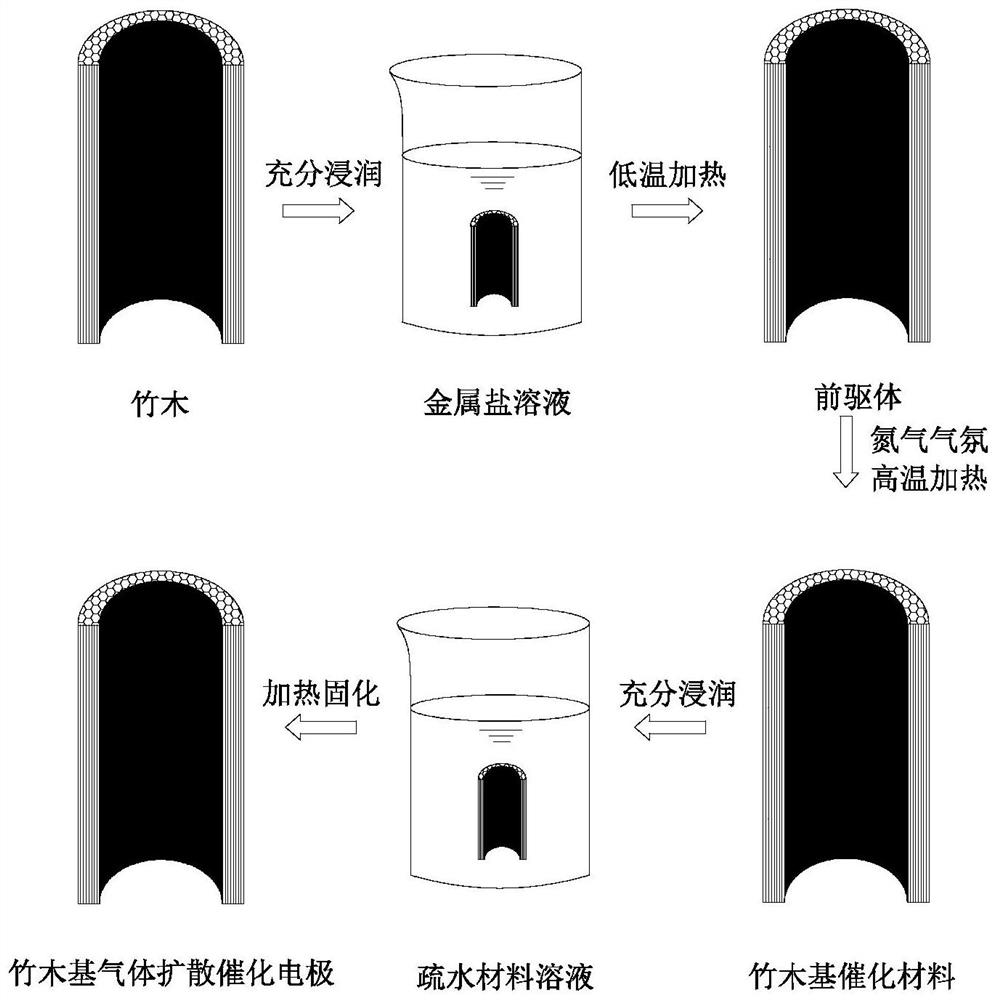

[0027] Reference manual attached figure 1 , a method for preparing a bamboo-wood-based gas diffusion catalytic electrode, comprising the steps of:

[0028] Step 1: Dissolve the metal salt in water, fully immerse the bamboo and wood material, remove the water by heating at low temperature after taking it out, and obtain the bamboo and wood precursor; preferably, take out the bamboo and wood material from the metal salt solution and remove the impregnated bamboo and wood material. The metal solution residue on the outer surface of the wood material can prevent the metal load on the outer surface of the bamboo and wood material from being too high. Wherein, in the catalytic electrode, the thickness of the bamboo and wood raw material is 1-4 cm. When the thickness is too low, the reaction area is too small, which is not conducive to the increase of the electrolysis current; when the thickness is too high, the lateral mass transfer rate will limit the reaction rate of the outer are...

Embodiment 1

[0040] A preparation method of a bamboo-wood-based gas diffusion catalytic electrode, comprising the following steps:

[0041] Step 1: Immerse dried bamboo wood in copper nitrate solution, the mass ratio of bamboo wood material to copper nitrate is 10:1, after soaking overnight, take it out, and heat at 353K for 6 hours to obtain the precursor;

[0042] Step 2: Place the precursor in a tube furnace, and perform a high-temperature heating reaction in an ammonia atmosphere: raise the temperature to 673K at a rate of 2K / min, keep the temperature constant for 2h, then continue to heat up to 1073K, and keep the temperature constant for 1h; when cooling down, First cool down to 573K at a rate of 2K / min, and then cool naturally to room temperature to obtain bamboo and wood-based biomass materials;

[0043] Step 3: immerse the bamboo and wood biomass material in 10% PTFE solution, and sonicate for 10s. After taking it out, the material was placed in a tube furnace and heated at a l...

Embodiment 2

[0045] A preparation method of a bamboo-wood-based gas diffusion catalytic electrode, comprising the following steps:

[0046] Step 1: Immerse dried bamboo and wood in nickel nitrate solution, the mass ratio of bamboo and wood material to nickel nitrate is 100:1, after soaking overnight, take it out, and heat at 353K for 6 hours to obtain the precursor;

[0047] Step 2: Place the precursor in a tube furnace, and perform a high-temperature heating reaction in an ammonia atmosphere: raise the temperature to 673K at a rate of 2K / min, keep the temperature constant for 2h, then continue to heat up to 1073K, and keep the temperature constant for 1h; when cooling down, First cool down to 573K at a rate of 2K / min, and then cool naturally to room temperature to obtain bamboo and wood-based biomass materials;

[0048] Step 3: immerse the bamboo and wood biomass material in 10% PTFE solution, and sonicate for 10s. After taking it out, the material was placed in a tube furnace and heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com