Gasification slag fertilizer and composting method

A technology for gasification slag and composting, which is applied in the preparation of organic fertilizers, organic fertilizers, and excretion of fertilizers, etc., can solve the problems of ineffective utilization of gasification slag and N loss, and achieve the effect of promoting composting, reducing N loss and reducing Effects of Ammonia Emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0061] This preparation example is used to illustrate the preparation method of gasification slag

[0062] The black water comes from the crude synthesis gas from the gasifier, which is sprayed and washed with water by the Venturi scrubber and the scrubber, and then flashed to produce a process medium with a relatively high solid content (10%-15%).

[0063] The gasification slag in the black water is processed by removing floating beads using a device for removing floating beads. The device for removing floating beads includes a separation tank, a settling tank and a buffer tank. The separation tank includes a separation chamber and a stirring tank arranged in the separation chamber. The black water inlet, the dilution water inlet and the black water outlet communicated with the separation chamber, and the stirring member is set to stir the black water entering the separation chamber so that the black water adheres to the gasification slag and is wrapped in the gasification sla...

Embodiment

[0066] This example is used to illustrate the method of composting.

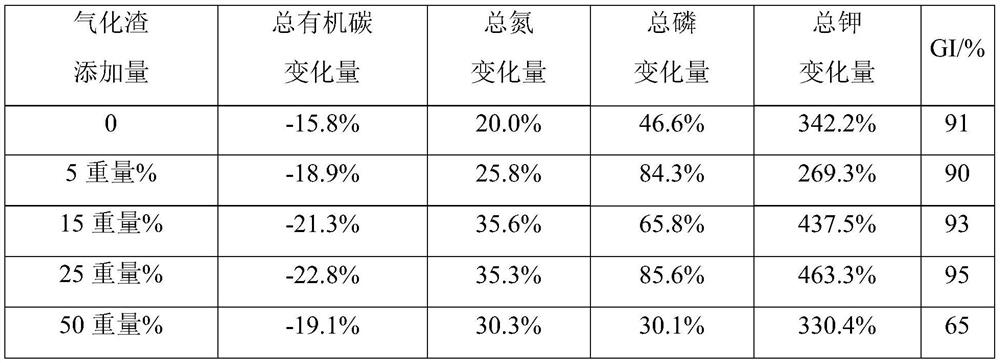

[0067] (1) Add crushed straw (0.5-1.5cm in particle size), chicken manure and the gasification slag prepared in Preparation Example 1 to the composting raw material, and mix them uniformly to obtain the composting raw material, wherein the amount of each component is such that The carbon-to-nitrogen ratio of compost raw materials is in the range of 38-44, the water content is in the range of 50-60%, and the consumption of gasification slag is respectively 0% by weight (that is, no gasification slag is added), 5% by weight, 15% by weight, 25% by weight, 50% by weight;

[0068] (2) Put the composting raw materials into the compost bin to pile up into strips with a height of 0.5 meters and a diameter of 1.0 meters to obtain a fermentation heap and leave it to ferment; wherein, the bottom of the compost bin is equipped with a stainless steel screen (screen aperture diameter 1-2mm), the fermentation heap is plac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com