A prefabricated bridge pier all-round structural inspection and maintenance platform

A structural inspection, all-round technology, applied in bridges, bridge construction, bridge maintenance and other directions, can solve the problems of affecting the detection accuracy, inability to detect, accurate positioning and stop, etc., to reduce the detection risk, take up less space, and set up compact effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

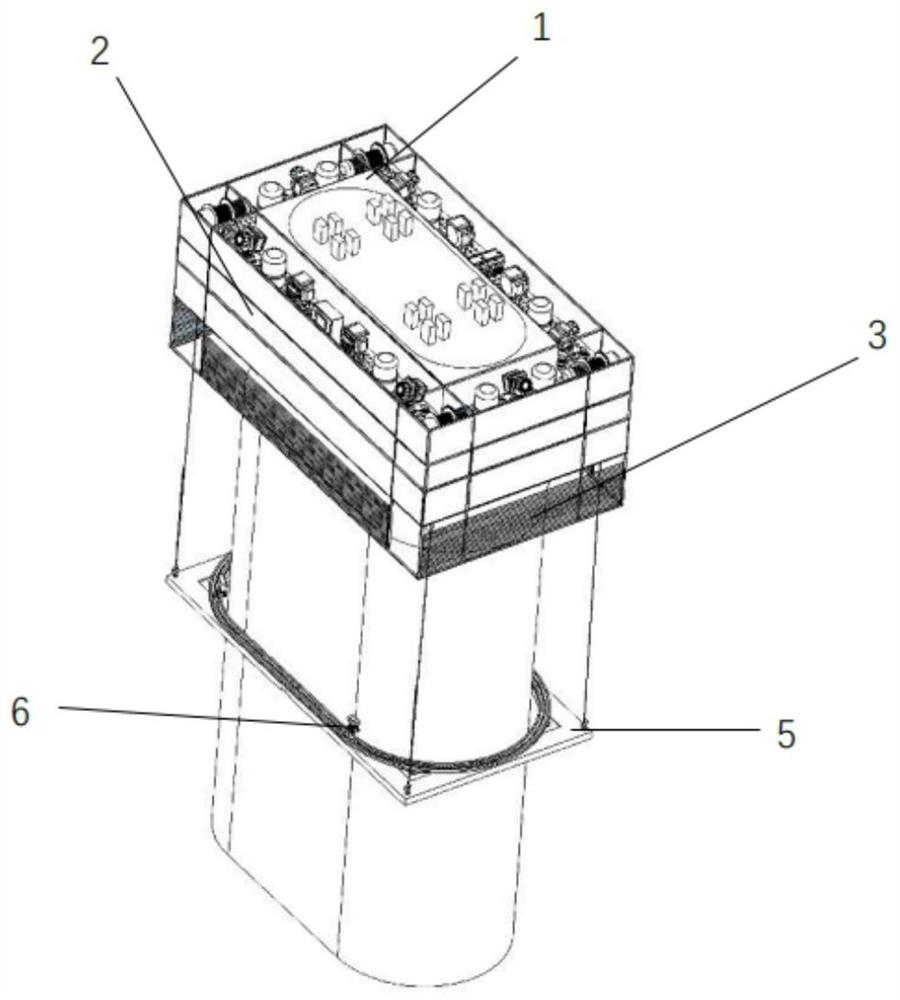

[0071] Such as figure 1 , a prefabricated bridge pier all-round structure detection and maintenance platform, including a prefabricated bridge pier surrounding structure, a carrying frame arranged above the prefabricated bridge pier surrounding structure, a lifting device arranged in the upper space of the carrying frame, and a hydraulic pressure device arranged in the lower space of the carrying frame Ballast platform and inspection and maintenance platform.

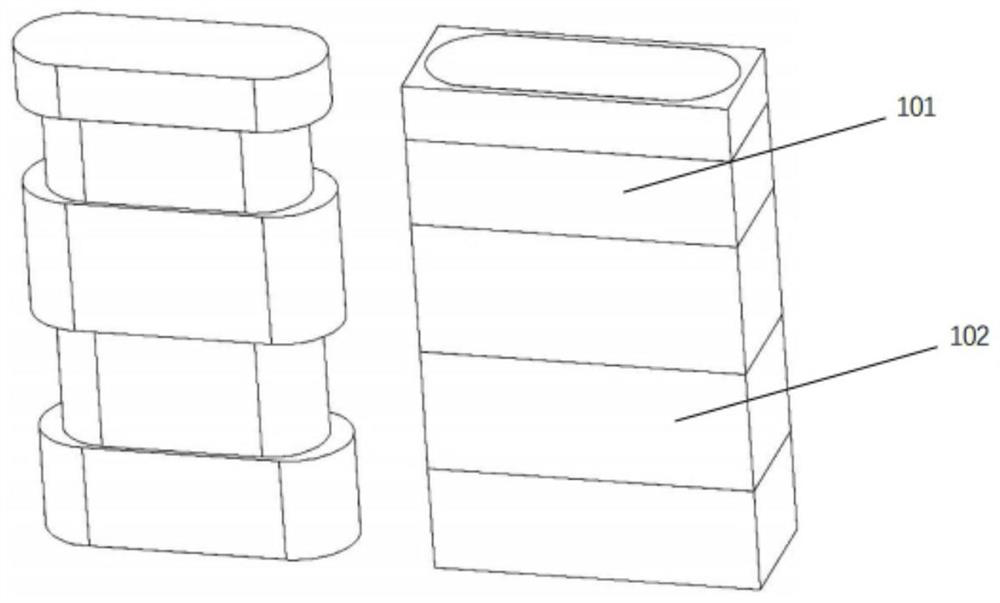

[0072] Such as image 3 , the surrounding structure of the prefabricated pier includes the upper and lower protruding concrete structures, and the prefabricated concrete structure cooperates with the reserved structure of the pier at the initial stage of the pier.

[0073] As shown in Figure 4(a)-(b), the four corners of the upper space where the frame is mounted are provided with lifting devices, and the upper platform is provided with early warning devices, detection storage devices and positioning storage devices. ...

Embodiment 2

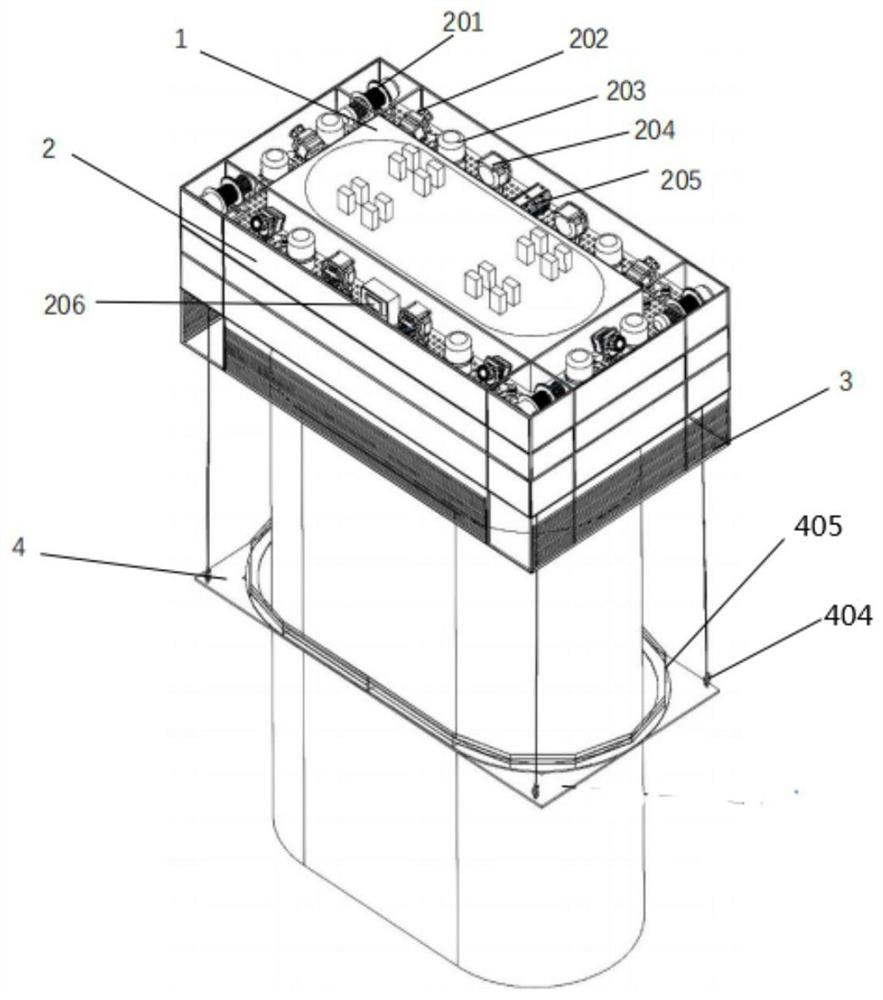

[0094] Such as figure 2 , this embodiment performs maintenance operations based on the platform. According to the test results of the bridge pier, the staff judges whether maintenance of the bridge pier is required.

[0095] After the detection work is completed, the staff judges whether maintenance is required for the pier. When maintenance is required, the staff disassembles and replaces the detection operation device of the detection maintenance platform and the maintenance operation device on the hydraulic ballast platform. When switching between the detection operation device and the maintenance operation device, the staff will disassemble the drive motor, transmission chain and bridge pier inspection equipment contained in the detection operation device. The structure, outer structure and safety guardrail are installed inside the transmission track, and then the first part and the second part are connected again, and then the staff leave the prefabricated pier all-roun...

Embodiment 3

[0104] In this embodiment, an early warning device, a detection storage device and a location storage device are provided on the upper platform carrying the frame. The early warning device includes an infrared sensor, a warning light and a siren.

[0105] The infrared sensor sends infrared rays to the surrounding waters, detects the speed and position information of the ships in the nearby waters, and sends the acquired speed and position information of the ships to the positioning storage device, and the positioning storage device judges whether the ships can safely pass through the waters under the bridge, Keep boats moving through the waters under the bridge at a safe speed. When it is judged that the ship is sailing at a dangerous speed or that the ship is in danger of colliding with the pier, the warning light will emit red light, and at the same time, the siren will emit a prompt voice to give an audible and visual warning to the corresponding ship.

[0106] The positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com